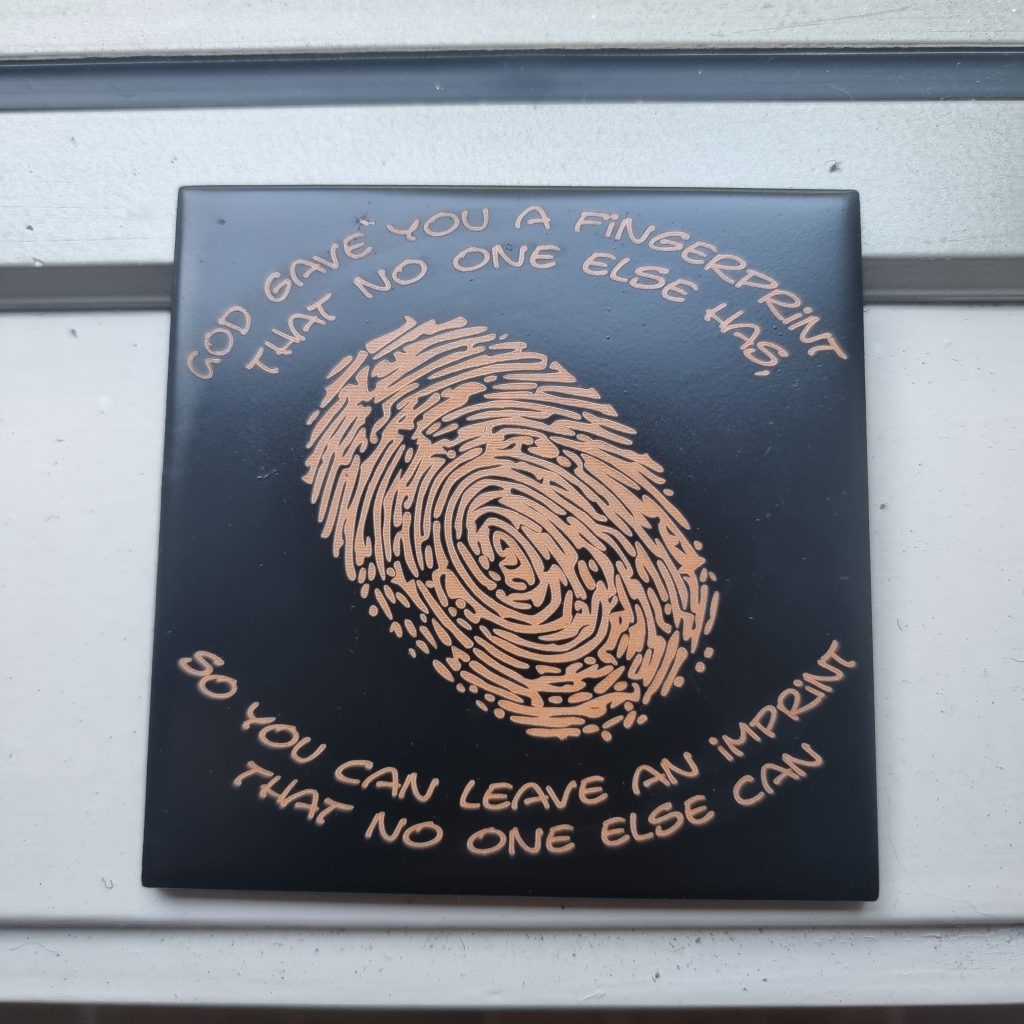

An impressive laser tile engraving. All you need to know!

Engraving on porcelain tiles

Diode lasers are awesome tools for CNC machines. Their ability to engraving and cutting a wide variety of materials is incredible. One of their most impressive abilities is engraving on porcelain.

To engrave on porcelain, a special procedure must be followed, a method,

Norton White Tile Method…

I discovered Nicky Norton’s Facebook group some months ago. The first thought of me, after seeing the engraved tiles, was to find the chance to make a big engraving on a wall or on a floor…

When someone ordered from me an image of kitchen tiles, I was really happy !

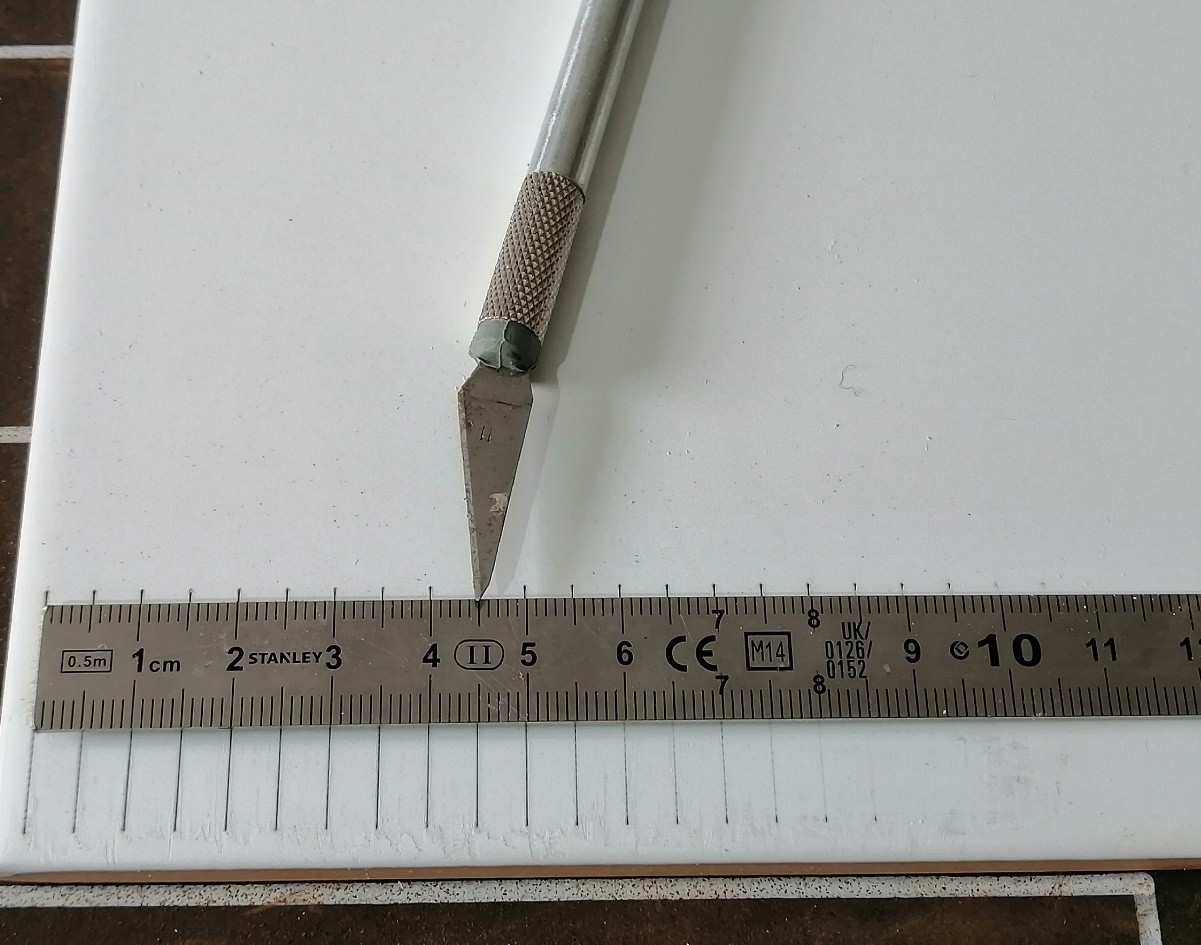

The material

was 200×200 mm white ceramic porcelain tiles which, there is no chance to engrave on them except if they are painted with a color spay with high content on Titanium dioxide (TiO₂). I used for this project Rustoleum Painters Touch spray.

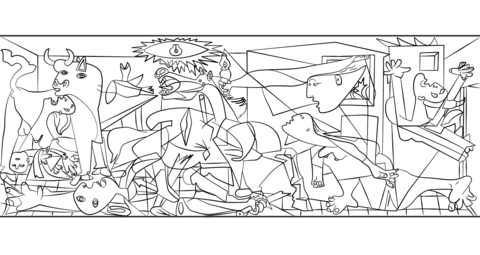

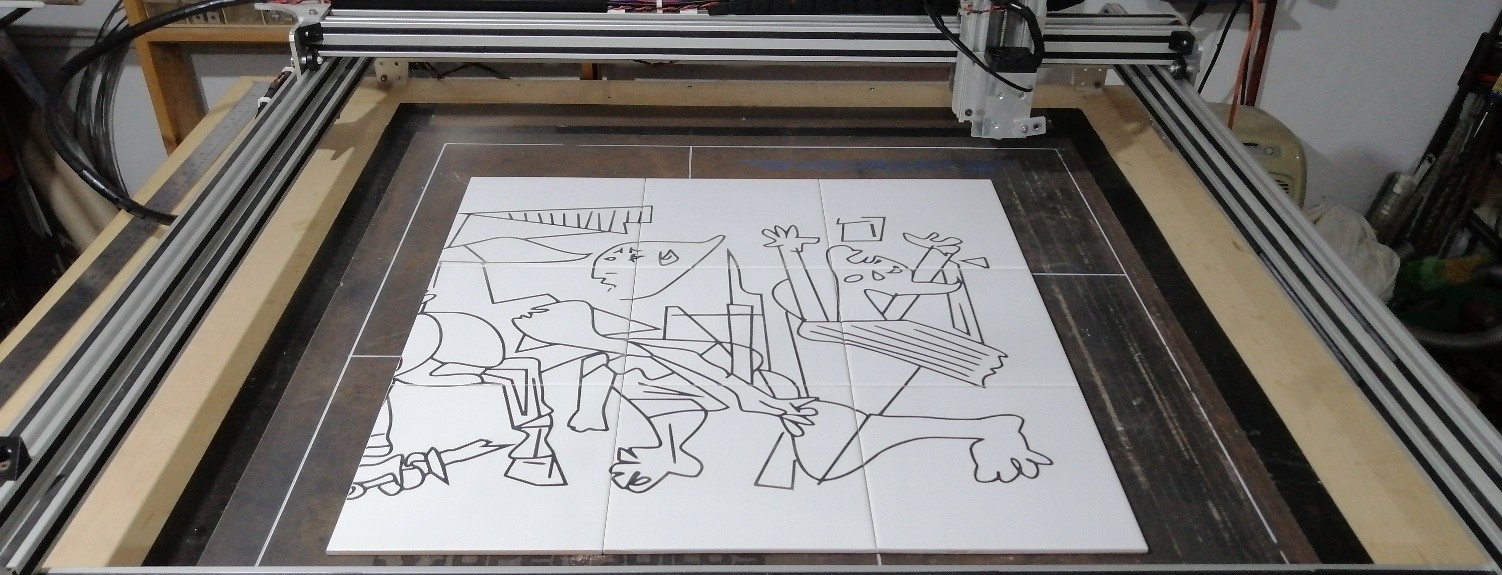

The image

The image is from a coloring book, I found online and transformed to DXF.

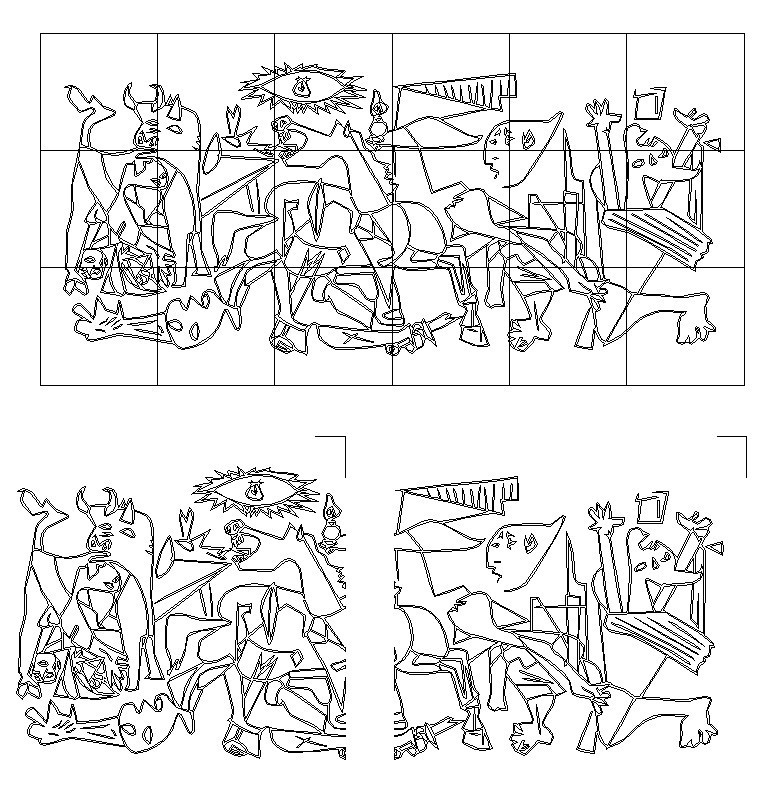

The dimensions of the image is 1120×500 mm, 18 tiles in total.

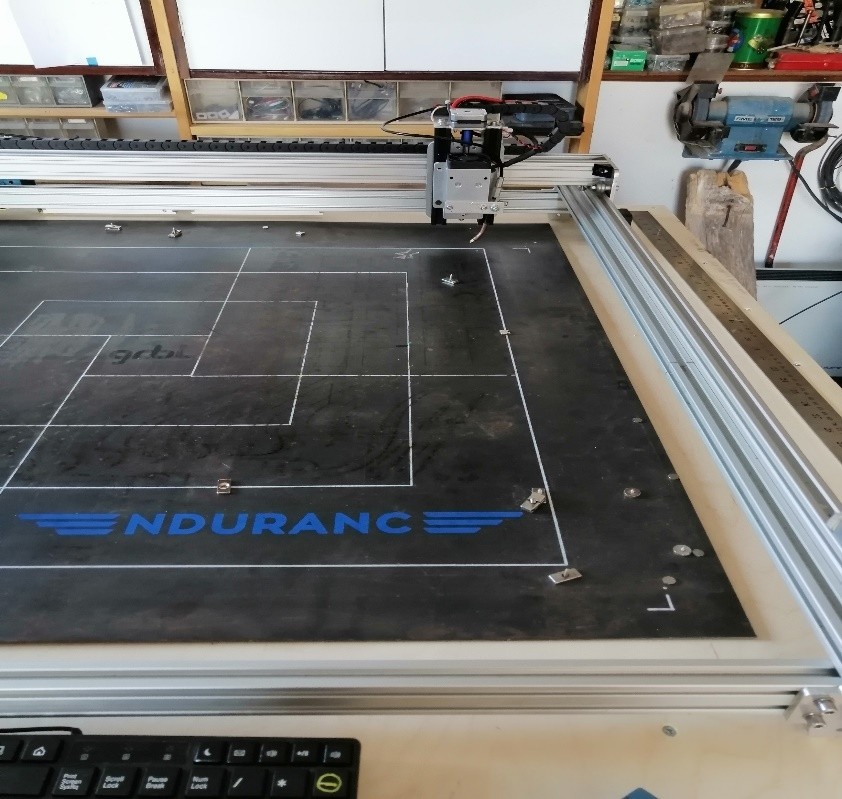

The engrave area of my shopmade CNC machine is 790×820, so I cut the image in half. 9 tiles for each part. I made a mark on the upper right side of each picture to help me align the image on the tiles. The grid on the machine’s worktop helped a lot to aline the tiles on it..

The thin Black Line…

The ideal focus of the lens is critical for the method

To find the smaller bean spot I use the z-axis. And a special g code based on one for 3d printers I found on the Endurance laser site.

After running the g code I have chosen by eye the thinner line and moved the z axis +4,5mm

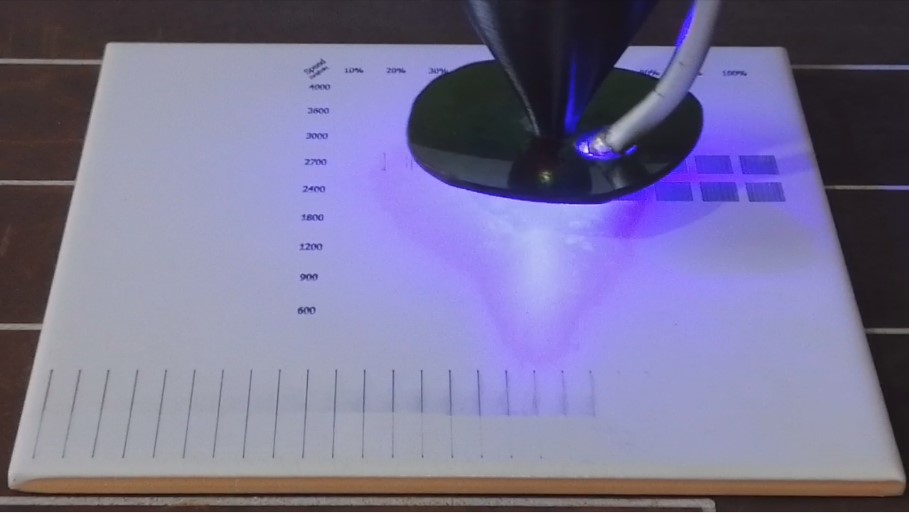

Having set the zoom is time to find out the best settings. For this reason engraving, a test card on the tile is very helpful. I used a file written by John Baynton-Glen ( https://www.facebook.com/groups/endurancelasers/permalink/1342982562753830)

At about 1600 mm/min with 70% power, I had a good result on black color.

CAM and settings

I use Vectric Aspire with a post-processor from J Tech (J TECH Dynamic Laser M4 No_Z)

Having some banding issues I used Cross Hatch at 45 degrees

Power: 70%

Feed Rate: 1600 mm/min

G-code sender and time…

I used OpenBuilds CONTROL as a g-code sender for the specific project

The left part took about 7h and the right one about 6h, both cross hatch…

Thoughts and results

- Low power lasers have a big advantage to NWT method on raster images due to the small bean spot and to the high Dpi.

- I believe that high-power lasers have a big advantage to NWT method on vector images reaching higher feed rates.

- Finding a way to replace the commercial sprays with (maybe !) pure TiO2 , would reduce the cost of the method.

- Air assist is not recommended from the method.

- It would be interesting to make some trials with a spacer on “invincible: -in order to have a smaller bean spot- . I have already ordered one from Endurace and it is on the way !…

Was done by Michail Gedeon

How to make a color image on white tile with the laser (Norton method)