Diode lasers have been gaining popularity recently.

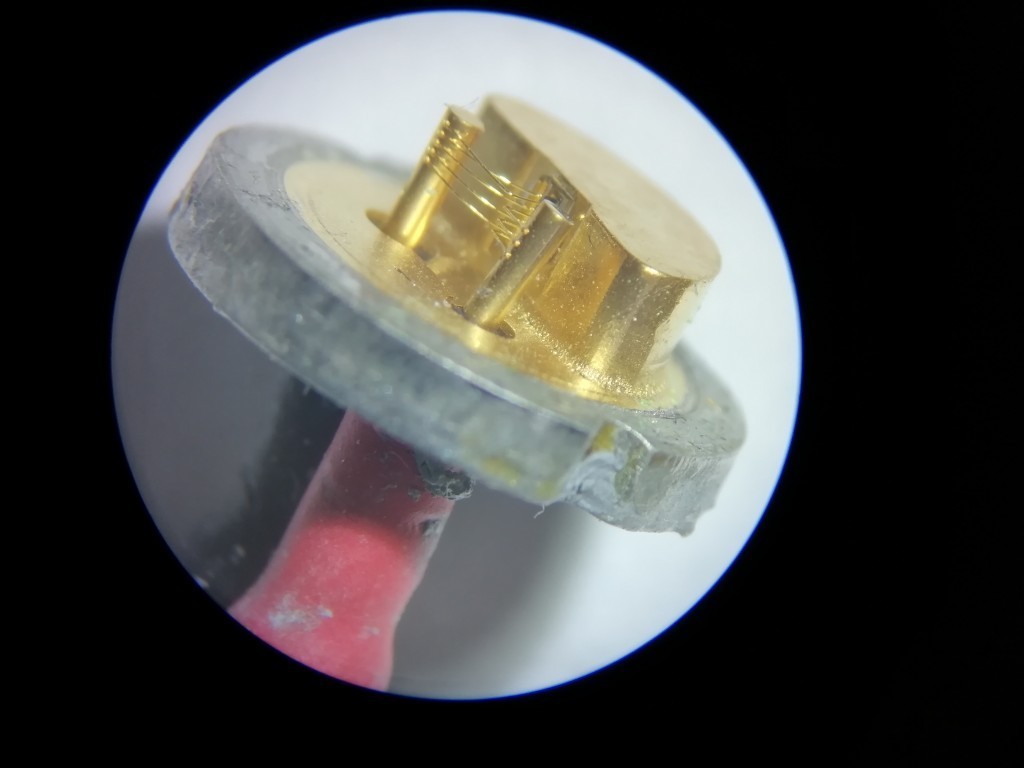

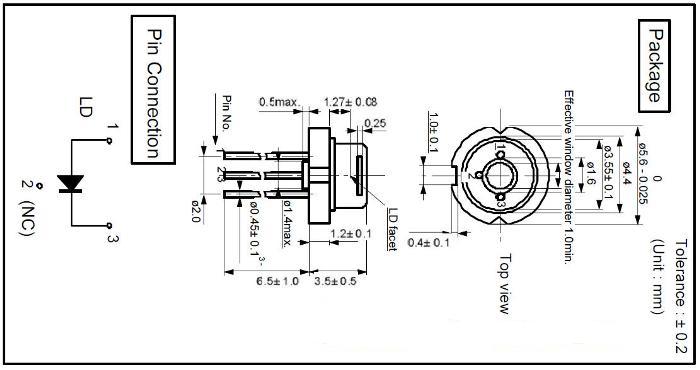

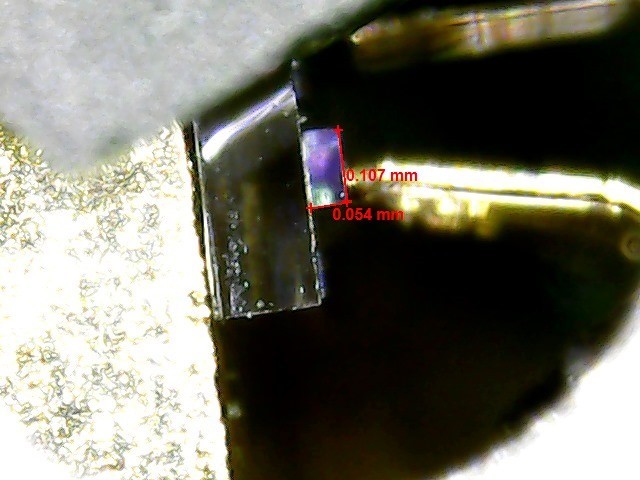

The technology of laser diode manufacture is rather complicated. Being a VERY SMALL piece, the laser diode has a multi-layer structure that makes the manufacturing process quite difficult and requires great skill. Quality is an essential feature for all laser types, that is why the number of high-quality laser diode manufacturers is limited.

One of them is NICHIA (Japan).

The structure of a laser diode

If you take a look at a wiki diagram you will notice that a multi-layer system is quite complex. https://upload.wikimedia.org/wikipedia/commons/thumb/c/c6/Simple_sch_laser_diode.svg/800px-Simple_sch_laser_diode.svg.png

A big problem and some limitation is heat conductivity. While generating photons (light), a laser diode creates much heat as well, which should be removed, that is why there are not so many powerful laser diodes on the market. The max by NICHIA NUBM44 / 47 has only 7-watt optical power output in a CW mode.

Of course, you can run it up to 10 watt in an impulse mode but that is almost its physical limit.

Applications of laser diodes

The field of the laser diode application depends on its wavelength. For example, 808 nm is commonly used for pumping DPSS (Diode-pumped solid-state) laser modules on Nd:YAG crystals. A lot of laser diodes are used in LED projectors.

They are also widely used in spectrography and in medicine.

On the research gate portal https://www.researchgate.net/ you can find a lot if interesting scientific research papers.

Advantage

The laser diodes’ biggest advantage is their size.

For example, a 7 watt NUBM44 from NICHIA is only 9 mm. If you want to get 10 watt out of an Nd:YAG you have to build a pretty big and complex machine, unlike in the case with diode lasers, which is why they are getting more and more popular.

Disadvantage

One of the biggest disadvantages of a diode laser is its beam quality. Most of the quite powerful laser diodes with an optical power over 1000 mW (1W) have a pretty low beam quality that makes it difficult to focus. Thus, you can focus a single-mode laser beam to as small a spot as a wavelength, while with a multi-mode laser it might be quite tricky to focus the beam to it a really tiny spot.

A constant wave (CW) mode vs. an impulse mode

Most laser diodes work great in a CW mode. For some applications that are very important. While the total power can reach a few watts the energy of a single pulse is just tiny.

Laser engraving and cutting abilities

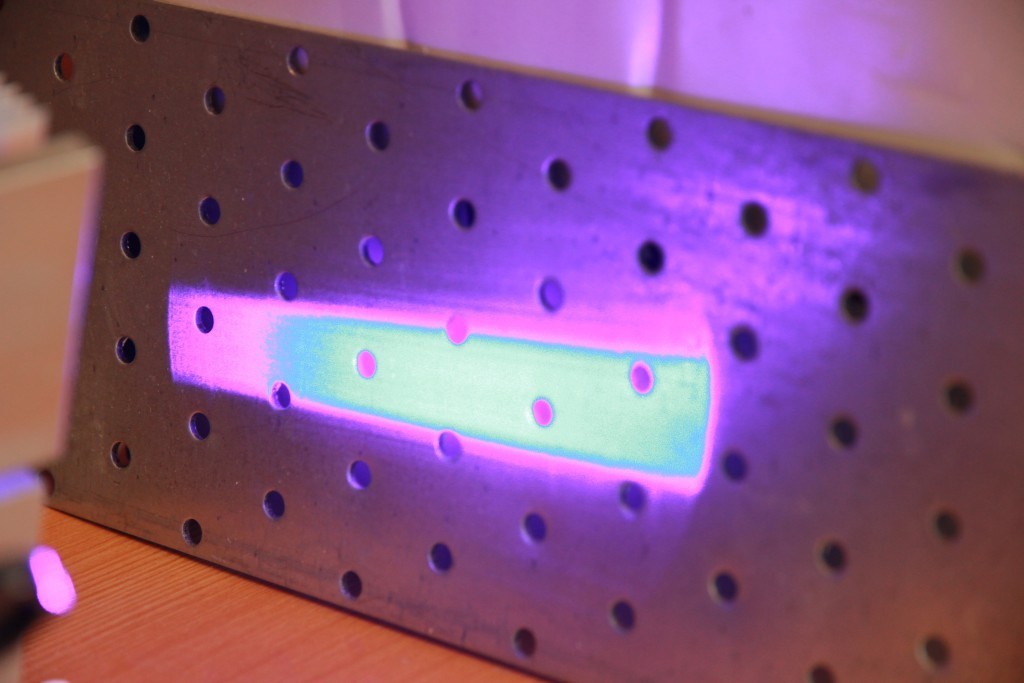

Some powerful lasers with 405 / 445 nm wavelength have become today’s favorite tools for engraving and cutting among makers and hobbyists.

That is because 5-7 watt of the optical laser power can easily cut up to 8 mm of acrylic and 6 mm of wood and plywood https://www.youtube.com/watch?v=7wN1fUY6KKE

https://endurancelasers.com/all-you-need-to-know-about-wood-and-plywood-laser-cutting/

For a better engraving and cutting process, you can use an air pump with an air-assist and get pretty decent results.

A diode laser is an affordable tool that can be installed on almost any 3D printer or a CNC router. There is a number of credible companies providing pretty reliable and endurable laser tools but stay away from Chinese fake lasers. They will not give you anything but bad emotions, absolute disappointment and zero support. https://endurancelasers.com/my-experience-with-non-branded-chinese-made-lasers/

If you are an experienced electrical engineer or you have plenty of time you can build your own laser based on open-source technology.

https://endurancelasers.com/diy-laser-kit/

Summing up, diode lasers are reliable universal tools for engraving and cutting of a wide variety of materials except transparent and metallic.

To cut metal you need high pulse energy impossible to get in a CW mode that is why high power Co2, Fiber or DPSS laser modules are mostly used for this purpose.

A video explaining how the diode laser works

https://www.youtube.com/watch?v=b1glooiyUq4

About diode lasers applications >>> https://endurancelasers.com/about-some-interesting-applications-of-diode-lasers/

More about diode lasers >>> https://endurancelasers.com/about-diode-solid-state-lasers/

Learn more about different types of lasers >>> https://endurancelasers.com/comparison-of-a-different-types-of-lasers-and-different-wavelength/