In this post we are describing some types of lasers: Co2, Solid-state, fiber & dye lasers.

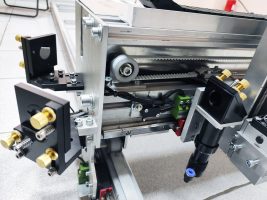

The CO2 (Carbon-Dioxide) Laser

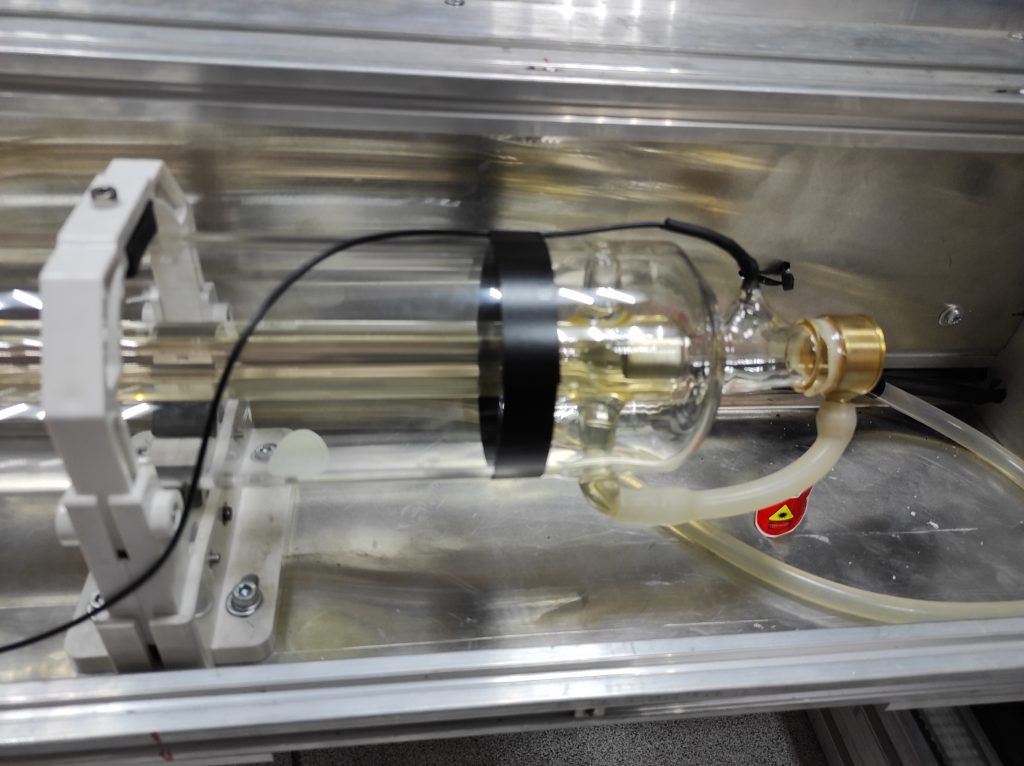

CO2 lasers are lasers using gas mixtures. Light amplification in these lasers occurs due to the vibrating transitions in CO2 molecules.

The gas laser operation concept

The nitrogen (N2) molecules transfer the pumping energy to the carbon- dioxide (CO2) molecules. The active medium in the tube is a gas mixture and consists, particularly, of carbon dioxide (CO2), nitrogen (N2) and Helium (He); sometimes it can additionally comprise hydrogen (H2), water vapors or xenon (Xe). The CO2 laser machine mode of operation is as follows: electric pumping excites the nitrogen molecules and makes them pass to a metastable state, in which they transfer their excitation energy to the CO2 molecules. An excited CO2 molecule emits a photon at the atomic level.

This photon collides with atoms of another excited CO2 molecule, which emits two photons. Thus, a great number of photons are generated in the tube. The other gases, helium, for example, depopulates the lower laser level and decreases the heat. Water vapor and hydrogen can turn carbon monoxide to carbon dioxide, and the reaction will start again from the beginning.

The tube has two mirrors. The first one is not transparent, usually made of copper (Cu), the second one at the beam exit is a semitransparent diamond mirror. Due to its high resistance and insensitivity to thermal shock, it ensures the safety of the whole system.

This is what makes the photons go through, but not all of them. A number of particles remain in the tube to reproduce its kind. Leaving the semitransparent mirror, the photons get to the spatial filter, which cleans the laser from side modes, then to the lens collecting the particles into a direct beam.

All the photons have the same wavelength, move parallel to each other, that is why the laser beam does not diffuse, unlike ordinary light. Modern CO2 laser cutters are horizontal, hence to direct the beam to the workpiece a mirror system reflecting the beam at the right angle is used.

The CO2 laser wavelength is 10,6 μm. The average power varies between a few tens of watt and some kilowatts.

Types of gas lasers used with CNC

- No-flow lasers with sealed tubes. Their power ranges from some watts to some hundreds of watts. The no-flow lasers differ from its counterparts by the fact that the gas and the entire beam path are inside the tube. Gas tubes are endurable compact units with a lifetime of thousands of hours.

- The laser with the fast axial and transverse flow. The excess heat in this laser is absorbed by a fast flow of a gas mixture that passes through an external cooling element, such as water. This type of the laser produces a power of several kilowatts.

- Diffuse cooling lasers. Gas in this laser is placed between two flat RF-electrodes with water cooling. The generated excess heat is transferred to the electrodes by diffusion. This laser generates a power of several kilowatts.

- Lasers with a transversely excited medium. They is characterized by high gas pressure. Transverse excitations are performed by a row of electrodes located along the tube, as the voltage required for a longitudinal discharge quickly becomes high. Since the gas discharge cannot be stable under high pressure in the tube, this type of laser can only work in a pulsed mode. The laser with a transversely excited medium produces a power of several tens of kilowatts;

- The Co2 laser with a power of several megawatts. They are used in antimissile weapons. The distinctive feature of these powerful lasers is that the energy is transferred not by means of a gas discharge but by means of a chemical reaction, which provides for huge output power.

Advantages of CO2 laser machines for cutting

- High-quality cutting, delicate cuts and edges;

- High effectiveness due to high power;

- High-speed operation due to high power;

- The absence of solid waste as CO2 lasers use gas as an active medium.

- Low level of noise and vibration. The laser generates radiation inside a locked tube, which absorbs any additional vibrations.

- A wide range of processed materials.CO2 lasers cut plastic, fabric, leather, cardboard, paper;

- Low energy consumption;

- CO2 laser machine software makes it possible to perform complex cutting, thereby turning a complex virtual model into reality;

- Choice of the radiation intensity. You can choose a laser intensity mode, which ensures the processing of different types of materials and making indentation and cuts of various depth.

- Defectless operation. СО2 machines are equipped with a CNC software, due to which the laser performs accurate movements and cuts according to the design in the program.

- Possibility to cut flexible materials such as paper or fabric due to the absence of contact between the carriage and the surface of the processed material.

- Compatibility of the components. Thus, a laser tube can be easily substituted with another one.

- Easy maintenance;

- No need to further process the edges. Thanks to the high power of the CO2 laser, cuts and edges are clean and accurate and do not require polishing or additional treatment.

- Compactness. CO2 lasers are compact and don’t need much space.

CO2 laser drawbacks when cutting or engraving:

- A limited volume of gas in the gas tube, which is gradually spent.

- The fragility of the gas tube. The tube made of glass can be broken when carelessly moved, transported or handled.

- Constant need in cooling. When inside a gas tube radiation is generated the temperature of the gas mixture increases. To prevent overheating of the CNC CO2 machine, which will result in its damage, it is necessary to use a cooling system to cool the gad tube.

- Different power for different materials. This is when an advantage turns into a disadvantage. Materials of various nature need a corresponding laser power for cutting. Otherwise, an item will be damaged.

- A malfunction at low power.

- Limited possibilities of work with metal. CO2 laser is able only to engrave metal.

To summarize we may conclude that CO2 lasers are the most powerful tools for cutting, engraving, polishing and other processing operations for materials of various types. CO2 laser machines don’t make waste because their cutting tool is a laser beam generated by atoms in a gas tube.

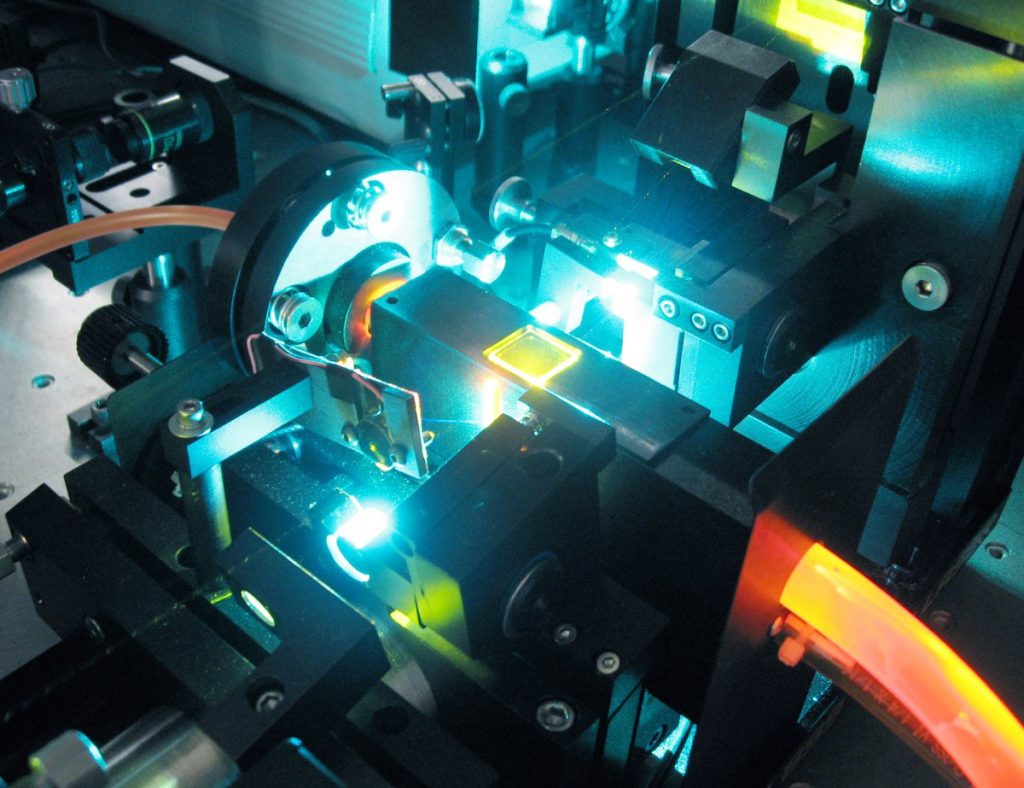

Dye Lasers

These lasers are called dye lasers because they use a solution of aniline dyes in water, alcohol, acid and other solvents as their lasing medium. The medium is in a dye cell placed between the laser mirrors. The energy of the dye molecule is pumped optically, only instead of a flash lamp pulse ruby lasers were firstly used, and laser – gas lasers. A pumping laser is mounted outside the fluid-state laser, not inside the laser, with its beam directed to the cell through a window in the laser housing. Today it is also possible to generate a beam with a flash lamp but not for all dyes. The liquids can emit light pulses of various wavelengths – from ultraviolet to infrared with a power of from several hundreds of kilowatts to several megawatts (millions of watts) depending on the dye type in the cell. Dye lasers have one peculiarity. They all have the same wavelength. This feature is based on the nature of the stimulated emission of atoms, which, in its turn, is the ground of the laser effect. In large and heavy molecules of organic dyes, stimulated emission occurs immediately in a wide wavelength band. To achieve monochromaticity from the dye laser, a light filter is placed in the path of the beam. This is not just a tinted glass. This is a set of glass plates that transmit light of only one wavelength. Changing the spacing between the plates, it is possible to lightly change the laser wavelength. Such a laser is called tunable. It is enough to change a lasing liquid cuvette to make the laser generate light in different parts of the specter: to go from blue light to red, or from ultraviolet to green. They are most high-potential for the structure research of any matter. By tuning the radiation frequency, you can find out which wavelength of light is absorbed or diffused along the path of the beam. In this way, it is possible to determine the composition of the atmosphere and clouds at a distance of up to two hundred kilometers, to measure the pollution of water or air, determining at once what size particles pollute it. That is, you can build a device that automatically and continuously controls the purity of water and air.

But along with broadband liquid lasers, there are those, in which the monochromaticity is, on the contrary, much higher than that of solid-state or gas lasers.

The laser wavelength can alter, becoming shorter or longer by some one hundredth (with good lasers). The shorter is the distance the mirrors, the wider is the band. For semiconductor lasers, for example, it is already several wavelengths, and for a laser-based on Neodymium salts, this band is one ten-thousandth. Such constancy of the wavelength can be obtained only with large gas lasers, and even then, if we take all the necessary measures for this: ensure the stability of the temperature of the tube, the strength of the current supplying it, and include a system for automatic adjustment of the radiation wavelength into the laser circuit. In this case, the radiation power should be minimal: with its increase, the band expands. On the other hand, in a liquid Neodymium laser, a narrow emission band is natural and it remains unchanged even with a noticeable increase in the radiation power, which is extremely important for all kinds of accurate measurements.

Therefore, the accuracy of measurements depends on how accurately the wavelength of the light emitted by the laser is maintained. A 100-fold decrease in the laser radiation bandwidth promises a 100-fold increase in the length measurement accuracy.

Solid-State Lasers

Solid-state lasers use a solid active medium such as: glass and crystals (unlike gas in gas lasers and liquid in dye lasers) doped with rare-earth elements. Garnet crystals are the most commonly used in solid-state lasers. Yttrium aluminum garnets (YAG) crystals doped with erbium (Er) and Neodymium(Nd) are the most versatile laser crystals. Solid-state lasers with Neodymium phosphate glass have the most active pulses.

In solid-state lasers, light energy is used as a pumping source. Light sources such as flash lamps, arc lamps, or laser diodes are used to achieve pumping.

Types of Solid-State Lasers

Depending on the mode of the laser power output, there are continuous and pulsed lasers. Each of them finds application and has its own characteristics. The main difference is that pulsed solid-state lasers have higher power. Since for each discharge, the photons are “accumulated”, one pulse is capable of producing more energy than continuous generation over a similar period of time. The less the impulse lasts, the more powerful each discharge is. Lasers that emit ultrashort pulses, of the order of femtoseconds to ten picoseconds, are called ultrafast lasers or femtosecond lasers.

Solid-state lasers are becoming more widespread in various areas of life and production. Air-cooled solid-state lasers are becoming less expensive and, therefore, more attractive for users.

Due to their by high beam quality, solid-state lasers are perfect not only for metal cutting but also for welding. Today, they are used in new technologies of electronic devices, in medicine, optical information processing, in integral and fiber optics, laser spectroscopy, laser chemistry, nonlinear optics, ultrafast photography, seismographs and various physical devices.

Laser engraving

Solid-state lasers are becoming more and more popular for laser engraving. The laser beam burns out shallow grooves according to the maker’s design, leaving the rest of the processed surface of the item intact. It is optimal to choose a solid-state pulse laser for engraving in terms of the power-to-price ratio.

Fiber laser

Fiber lasers are a special kind of solid-state lasers, with high output power, high beam quality, broad wavelength specter, and high efficiency.

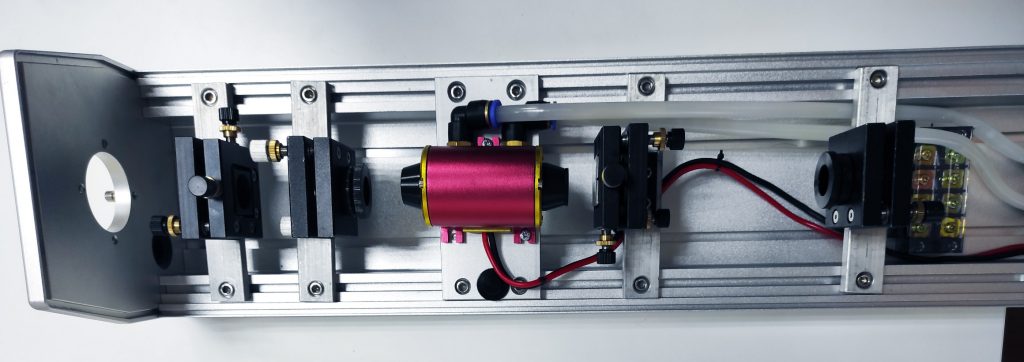

A fiber laser is a universal tool widely used in various fields of industry. Its efficiency is around 70%, which helps reduce time expenditure for works of any complexity. The device consists of two main parts: pumping lamps and an optical cable with a light conductivity fiber and a core of rock crystal inside.

The fiber laser is used for:

As a universal tool, the fiber laser is suitable for processing surfaces when a high-precision operation is required; it can cut even sharp angles. The main purpose of the fiber laser is a procession of metals of various thicknesses and densities.

It is widely used for:

building cars, vessels, air transport, rockets included;

building sea and railway cars, shipping containers;

making jewelry and engraving (the beam precision of the fiber laser allows doing most elaborate work);

production of metal structures in the construction of residential, office, retail facilities, as well as in the construction of metal advertising structures;

works in the military-industrial complex.

The fiber laser does a great job of processing stone (natural and artificial) as well as glass and some types of plastic.

The main differences between the fiber and gas lasers are as follows:

The fiber laser fits to process such materials as silver, copper, brass, while the gas laser is unable to do it. On the other hand, the CO2 laser copes better with paper, glass, plywood, wood and fabrics of various nature.

The fiber laser is easy to work with and does not require any special qualification. Its operating principle is clear enough. Due to its simple construction, the fiber laser can be installed on any small machine or a welding unit. Its key feature is an optically active or silica fiber, where the radiation generation takes place and from where goes to the processed material.

Advantages of the fiber laser over gas and solid-state lasers:

The fiber laser is a user-friendly, powerful device, indispensable in industry.

The fiber laser efficiency is around 70%. It is twice as high as that of other lasers.

It has an optimal wavelength, which remains stable during the entire operation period. This mode makes it possible to transmit the laser beam over a greater distance without loss and focus it to a tiny point, which is important when doing engraving or processing hard-to-rich areas.

High frequency of pulse repetition provides for performance stability when doing welding, marking or cutting of various materials. The power of the fiber laser radiation is great enough to ensure the weld strength, at the same time it prevents it from melting through.

The versatility of the fiber laser

The fiber laser does not need any special maintenance or cleaning. It does not require any special environmental conditions, so you can keep it (use) it in any place. It is also possible to upgrade the laser for new technological processes.

Since the fiber laser beam is strictly directed (focused) and is able to process a small size surface, the material around it is not heated. That’s why the use of this laser is safe for others. The fiber laser is a compact device suitable for a vast scope of applications.

Possible use cases

Co2 and diode laser

– cut wood fast and precise, to do wood inlay work with fine edges

– 2d engrave fast with details, to engrave paintings of different sizes

– 3d relief engrave fast and precise, to produce finer results than CNC

Fiber lasers

– cut some thin metal sheet such as copper and brass, 1 to 1.5mm

– 2d or 3d sub-surface engraving, bubblegram in glass, acrylics

30W cut 1mm brass

60W cut 1.5mm brass