All you need to know about how to pattering your smartphone case

Color Patternin of a Smartphone Case Using a DPSSL (Endurance 10 Watt DPSS Laser Nd: YAG, 1064 nm, F = 30mm).

Today we will tell you how to turn an ordinary plastic case for a smartphone into an exclusive and original Cyberpunk-style accessory.

For this task, we need a cell phone case (we’ve chosen a protective bumper for the Redmi Note 8 Pro model), acrylic paint sprays of different colors, and an Endurance laser machine CNC 3018.

The method of cell phone patterning is similar to the Norton method that we used to create images on ceramic tiles

Getting started

Here is the processing procedure in detail:

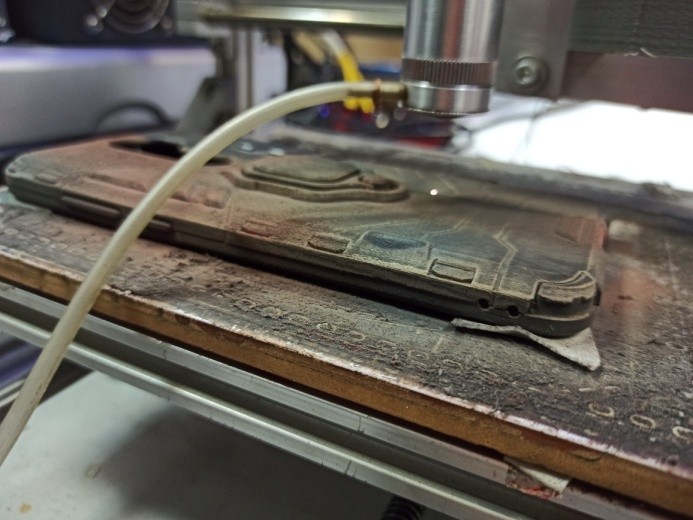

We spray various surface areas of the plastic phone case with paint of different colors in random succession. It is important that there is enough time between the paint applications for each color coating to get dry (about 10-15 minutes). We apply the paint in a thin and even layer. After we have finished color painting the phone case, we spray the entire surface of the case with black paint.

After painting, it’s better to leave the phone case for a day to completely dry (this is not obligatory, but it’s worthwhile to wait for a little).

Next steps – preparing

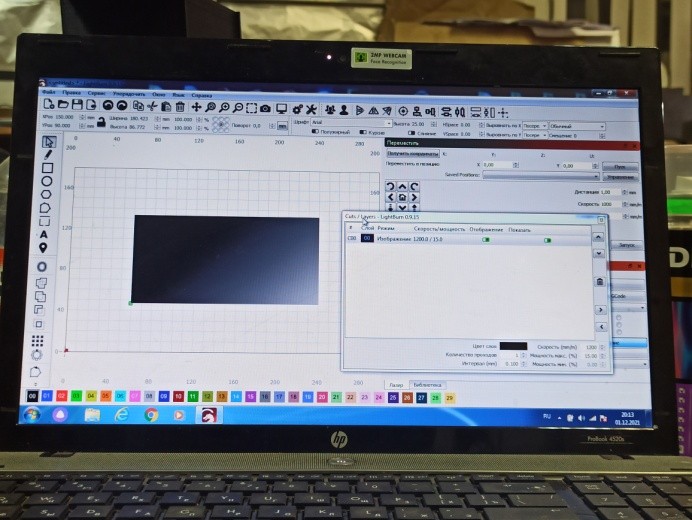

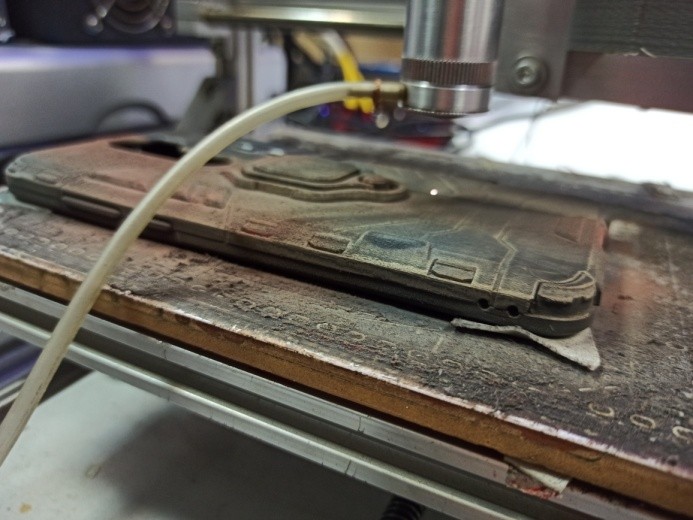

After the paint has completely dried, we place the painted case on the laser desktop and fix it with adhesive tape. Then we open a template for engraving in the LightBurn program (in our case, this is a normal black-and-white gradient), adjust the size of the template in accordance with the size of the case and select the following parameters of the laser operation: processing speed 1200 mm / min, power 15%, number of passes 1 , filling density 0.1 mm. The focal point is 2 mm above the work surface. After choosing the settings, we start the laser. It takes about an hour and a half to laser process a template, 85mm by 165mm in size,.

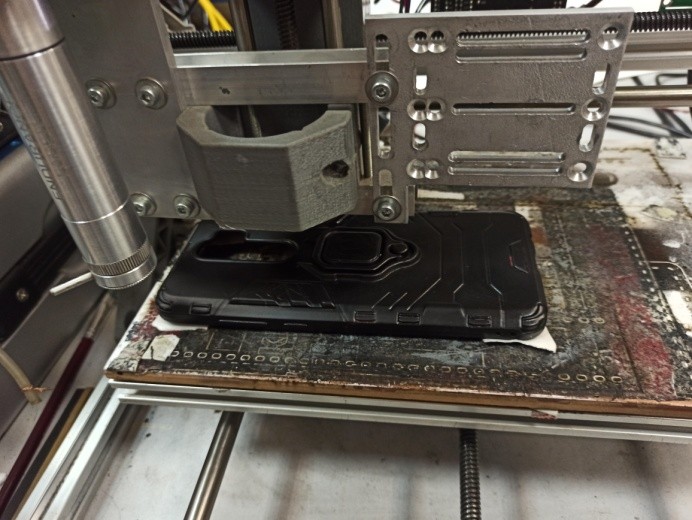

Lasering process

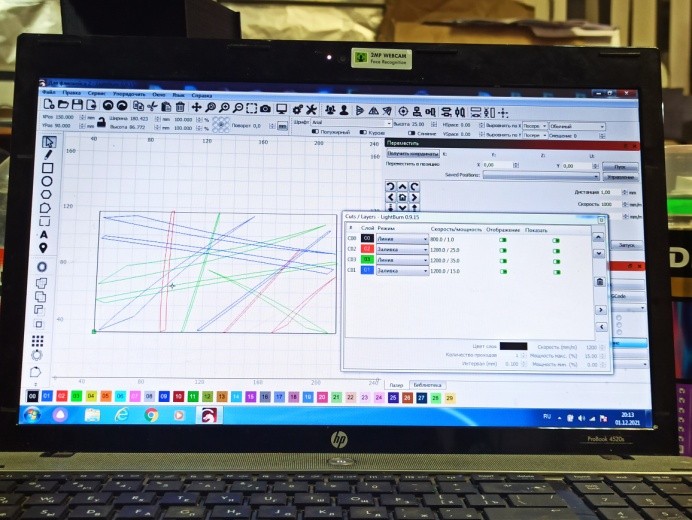

Upon completion of the lasing process, the case should be rinsed with water, after which you can see a new color of the surface. But the processing is not yet over. Our goal is to add a Cyberpunk style to our cell phone case. To do this, we place the case on the laser desktop again, and open another vector file pattern in LightBurn. Different elements of this pattern should be processed using different power parameters (15%, 25%, 35%) to obtain new various effects.

The general parameters of engraving are as follows: processing speed 1200 mm / min, number of passes 1, spacing 0.1 mm. After setting the parameters, we start the laser.

This stage of engraving requires much less time – a little more than 15 minutes since the processing is carried out using a template in the vector format. At the end of the laser operation, the case should be rinsed with water.

Now you can see the finished result. The case looks unusual and really cool.

That’s all. We hope you find it interesting.

How to cut Polyurethane Protection Film with a diode laser for your smartphone