In this article, we will look at how to properly apply QR on various types of black plastic using a laser.

To apply a QR code to the material, a 10 watt DPSS laser with a wavelength of 1064 nm was used with an RC1001 galvanometer. Lens mounted on an OPEX SL-1064-112-163G galvanometer, focal length 163 mm.

The original image from the customer (Fig. 1) was of poor quality and it was decided to redraw it (Fig. 2).

Figure 1 – The original image of the QR code

For the redrawn image, a color inversion was performed, and a frame was added around the edges. These actions were made to better read the QR code on black plastic, since when the image is burned on this material, the pattern becomes a color close to white.

Figure 2 – Redrawn QR code image

In the future, the text that was in the original image will be added in the laser control program itself.

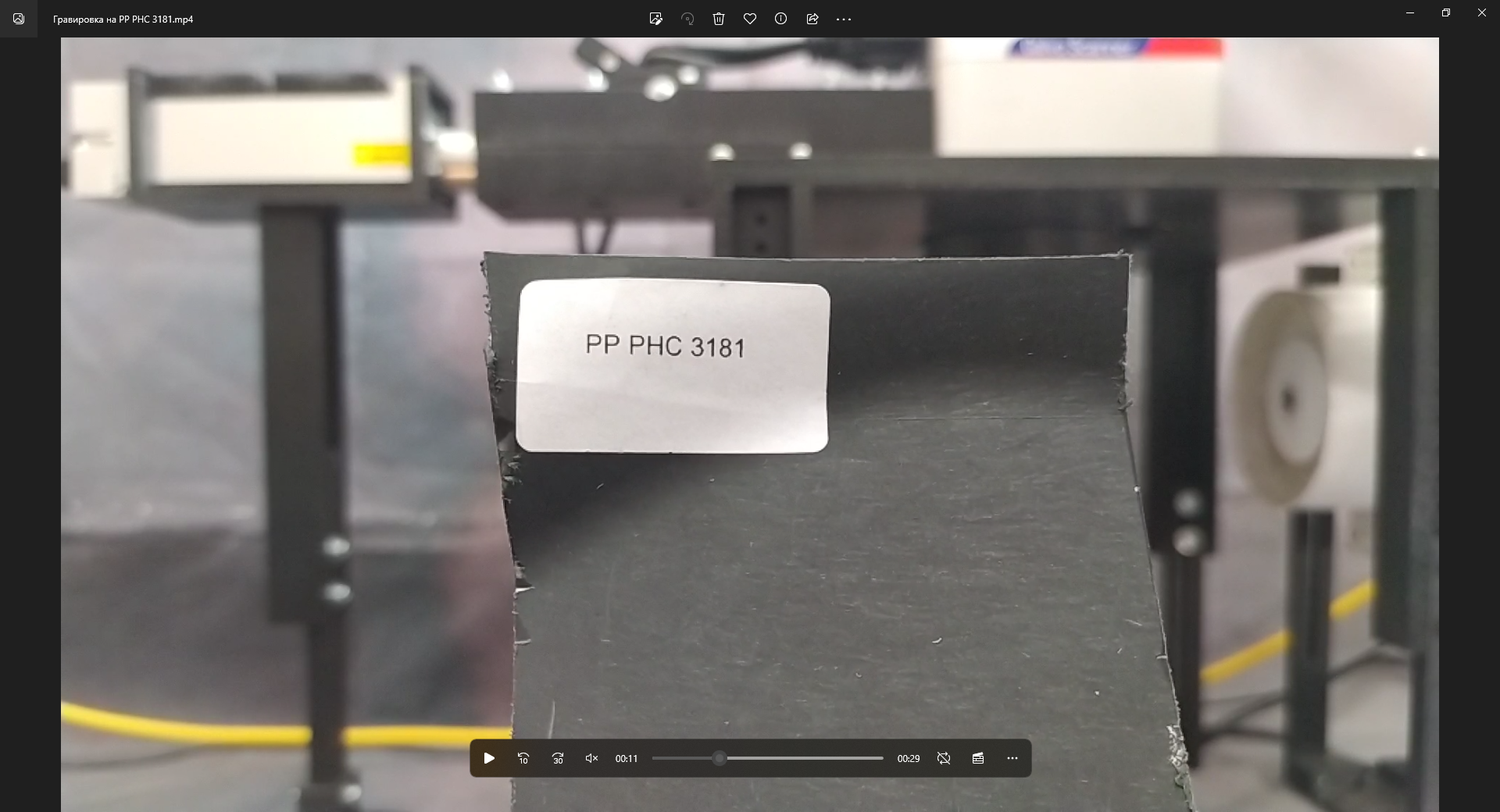

Material resembling elastic plastic PP PHC 3181

The following laser control parameters were set for this material:

number of repetitions – 1;

speed – 500 mm / s;

power – 50%;

frequency – 20 kHz.

The material before engraving is shown in Figure 3.

Figure 3 – Material before engraving the QR code

The material after engraving is shown in Figure 4.

igure 4 – Material after engraving a QR code

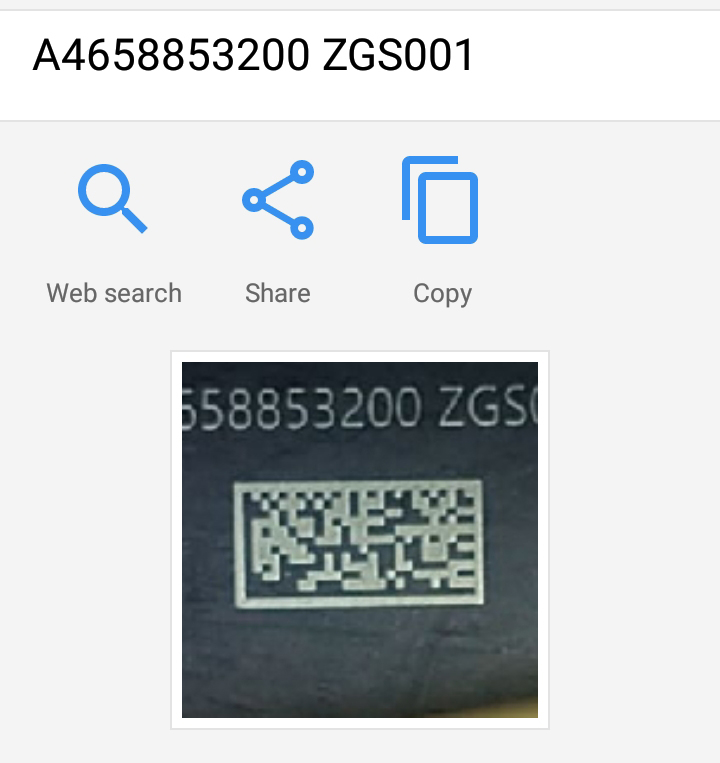

To check, we used a QR code scanner on the phone (Fig. 5).

Figure 5 – Scanning a QR code on a material

Based on Figures 4 and 5, we can conclude that the QR code is clearly visible and readable by the scanner.

Hard rubber material PP+20%GF

The following laser control parameters were set for this material:

the number of repetitions – 20;

speed – 250 mm / s;

power – 20%;

frequency – 20 kHz.

The material before engraving is shown in Figure 6.

Figure 6 – Material before engraving the QR code

The material after engraving is shown in Figure 7.

Figure 7 – Material after engraving a QR code

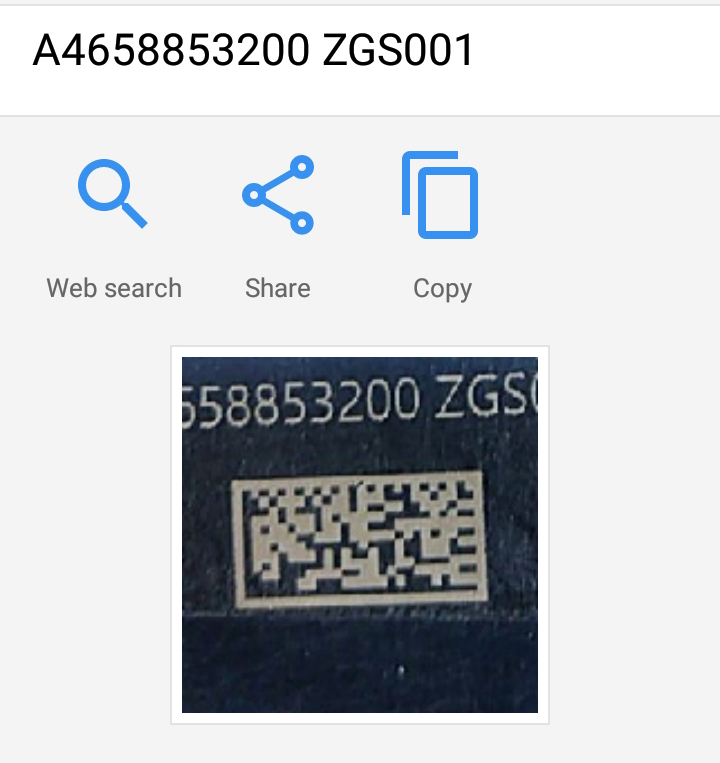

To check, we used a QR code scanner on the phone (Fig. 8).

Figure 8 – Scanning a QR code on a material

Based on Figures 7 and 8, we can conclude that the QR code is clearly visible and readable by the scanner.

Learn more about laser plastics engraving