Installation

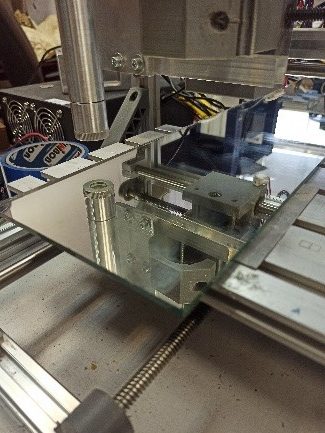

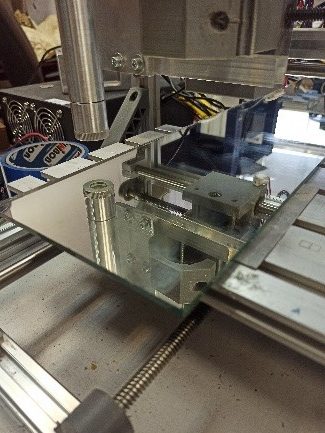

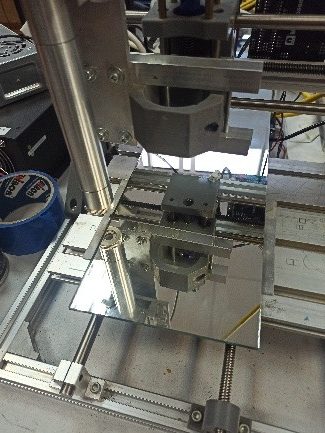

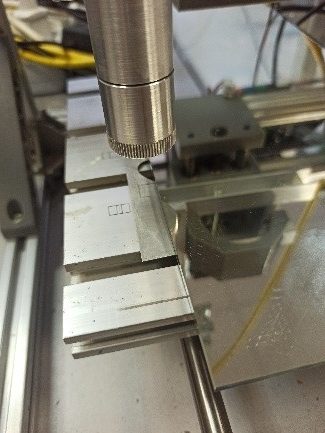

Experimental Mirror Cutting and Engraving with a Diode Laser (Endurance 10 Watt DPSS Laser Nd:YAG, 1064 nm, F=25mm) installed on CNC 3018 machine

What do we plan to do?

To cut off a piece of a mirror of a certain size, then engrave an inscription on its non-transparent surface.

Work procedure:

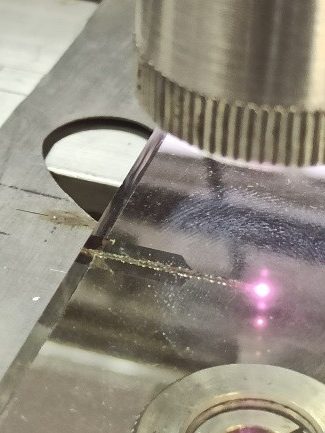

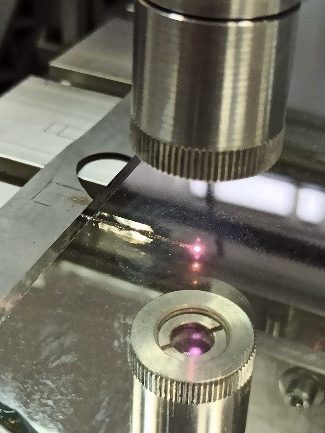

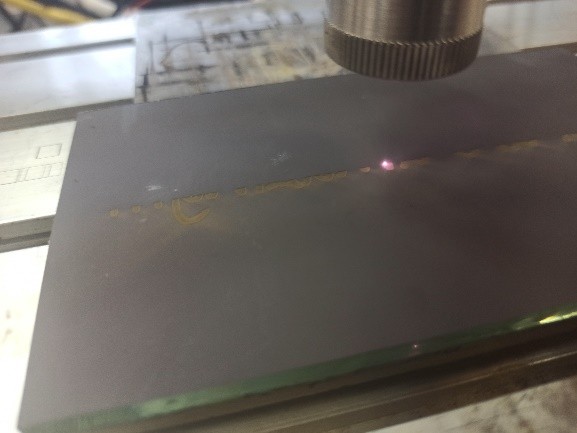

Laser cutting process

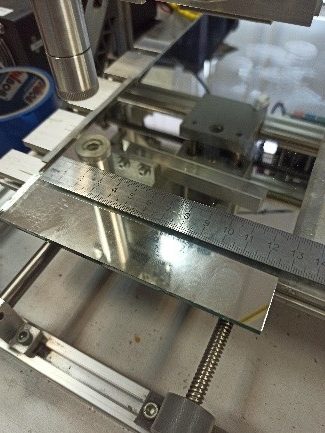

We need a piece of mirror 4 mm thick, 130 mm wide and 80 mm long. To cut it off we take a big mirror and place it on the worktable faceup. We do cutting with an Endurance 10 Watt DPSS Laser (https://endurancelasers.com/laser-engravers-and-cutters/) using LightBurn 0.9.15. The operation parameters are as follows: speed 20mm/sec. Power 99%, number of passes 1. The focus point is set to the lower (nontransparent) surface of the mirror or a little bit above it. The cutting pattern is a simple beeline drawn in the program. Now a workpiece is ready.

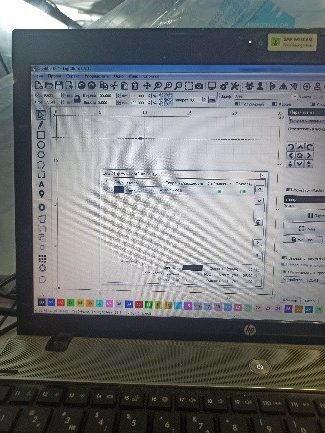

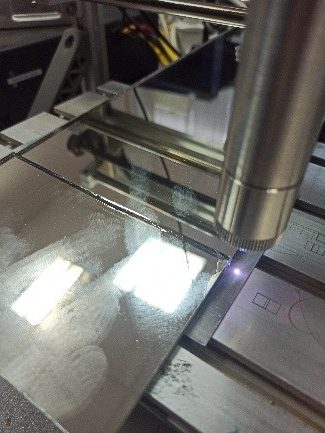

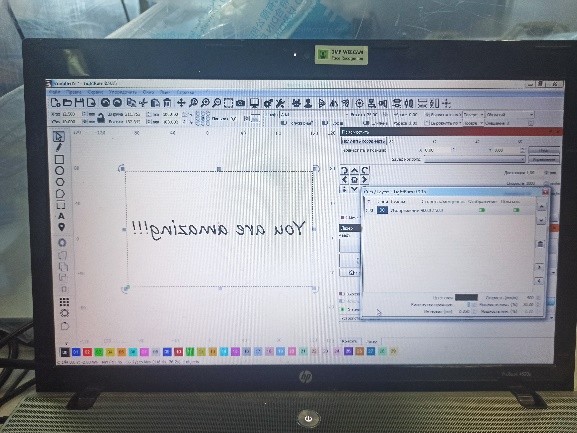

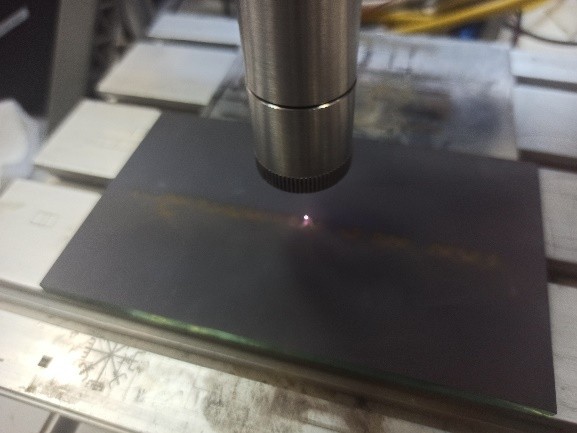

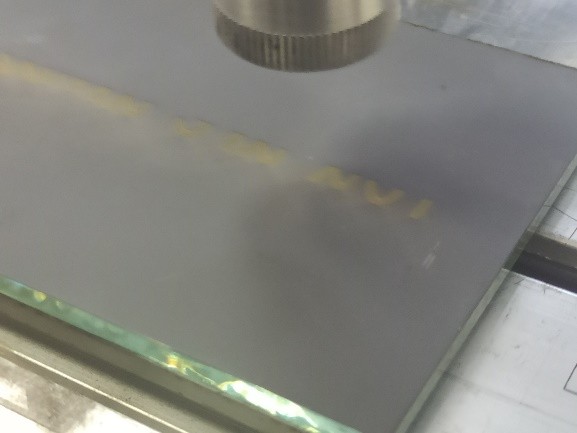

Laser engraving process

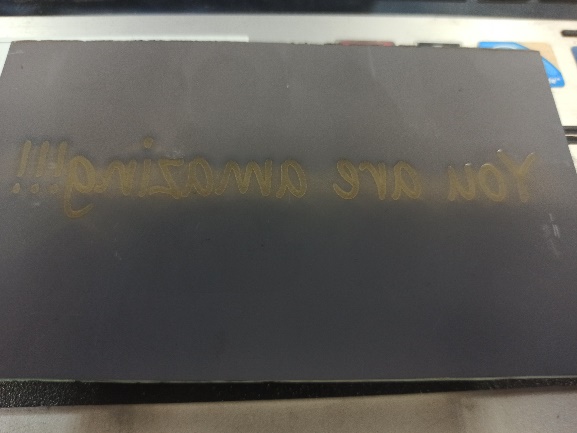

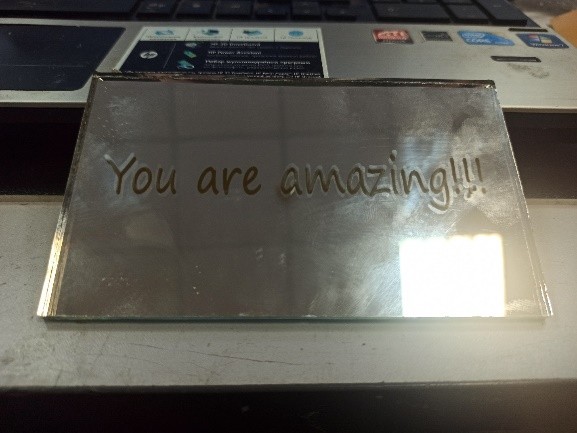

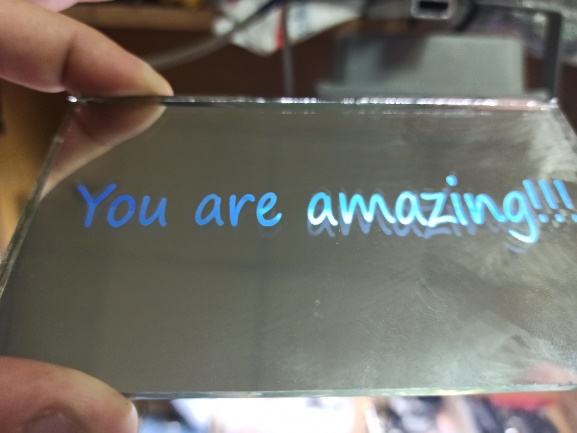

We upturn the workpiece (nontransparent surface up). In the LightBurn program, we open the inscription image as a jpeg or png file (it should be inverted). We focus the laser to the nontransparent surface of the mirror. Our task is to burn out the coating in specified areas. We set the necessary size of the inscription and the engraving parameters: speed 900 mm/s, power 50%, number of passes 1, interval 0.05 mm. This processing mode enables to evaporate of the mirror layer without damaging the glass. After positioning of the workpiece and setting of the mode parameters we start the laser. The engraving process took us 15 minutes. When the processing is over it is necessary to remove carbon deposits from the processed surface with alcohol or napkin.

Watch this video laser mirror cutting

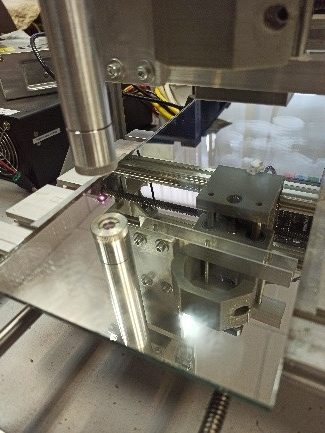

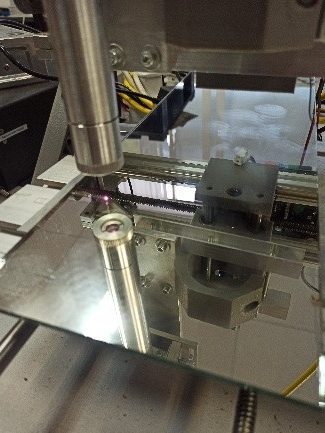

Mirror engraving on an Endurance DIY galvo frame

Enjoy the result!!!