A few days ago it occurred to me that our lasers with 2.1 watt / 3.5 watt / 5.6 watt might be very useful for 3D printing.

There was a problem that some plastics does not adhere well enough.

Sometimes we face a problem with plastics adherence. It occurs when plastic cools.

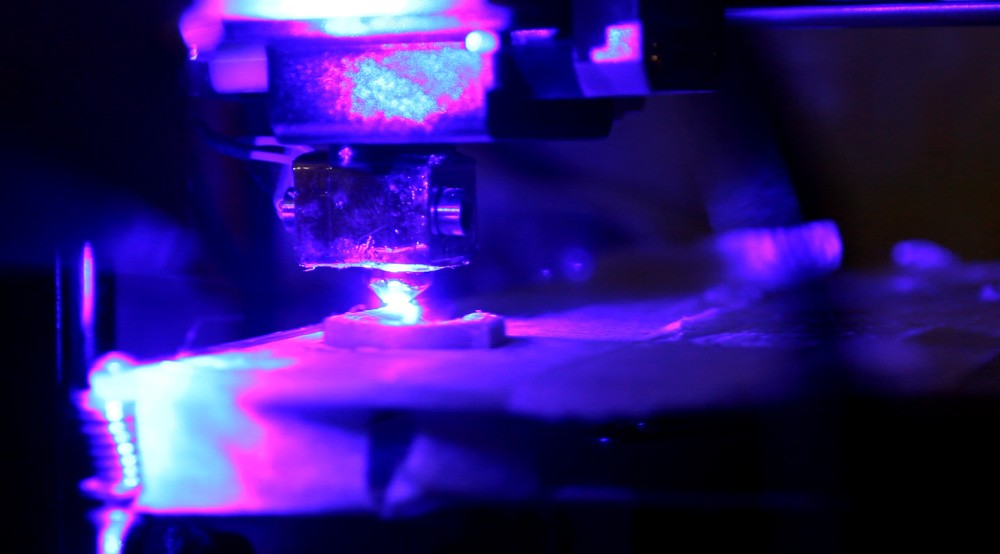

To improve this we mounted a laser on the 3D printer and aimed its scattered beam to the upper layer of the plastic to ensure the best adhesion.

Process description

So, the process is quite easy:

1. Mount the laser on your 3D printer and aim the beam 0.1-0.15mm down from the extruder

2. Defocus the laser, making the spot 0.2-0.25 mm in size.

3. Connect the laser to an external power source (the laser will work constantly while 3D printing)

4. Cover your 3D printer with a black / green or red acrylic pieces and run the 3D printer.

5. Enjoy the result.

Of course this technology is not very practical if you have high quality plastic and a very advanced 3D printer with perfect quality printing, however, additional thermo plastic processing will be quite useful and will make the surface of your printed item smoother!

What we got here

We got pretty good results.

Also laser kits are available for that.

Without the laser

With the laser

Let’s explore this life hack together.

Share your ideas and thoughs with us down below on our disqus board.