In this article, I want to highlight the key difference between diode, CO2, and fiber lasers.

Let’s start with diode lasers.

When you are working with diode laser’s you should always wear eye protection. The goggles that arrive with your Endurance laser are for your protection from long-term damage and they can help reduce the risk of the laser coming in contact accidentally with the eye.

Diode lasers can emit a range of power to engrave and cut on various materials such as wood, leather, acrylic, leather, glass, etc…

Diode lasers are more versatile lasers for consumers for their lower cost point and portability compared to bulkier and more expensive CO2 and fiber lasers. With ease, the diode laser can be modified and installed onto other types of CNC machines, 3d printers, and even CO2 machines. Endurance diodes are capable of utilizing various frames and their portability provides stability and performance when mounted onto other CNC machine frames.

Diode lasers vs. Co2 laser tubes. Advantages and disadvantages

A diode laser will successfully engrave on various materials. They can be used to engrave well, and with the installation of a proper lens, focus, and power, they can cut efficiently. Although other lasers such as a Fiber and Co2 specialize in their specific usages, the diode is appealing for engraving, size, and portability and also its lower cost point. Hobbyists and businesses owners can achieve various laser engraved results with the right diode laser. Endurance diode lasers can also cut and mark various materials down to the smallest detail at an efficient rate. It is small, yet powerful for achieving many types of engraving and cutting projects.

Absorption wavelength spectrum for different materials: glass, metal and others.

With an Endurance diode laser, there are far easier maintenance requirements, easier diagnostic for issues and they are also just the right lasers for a project.

The market for diode lasers has many laser manufacturers, but unfortunately navigating the various vendors can be problematic for beginners. Some newcomers to diode lasers may come across a manufacturer that does not always state the facts about their lasers and capabilities with what they claim and market to consumers. One instance is that people can come across is the outrageous claim of a high power output that makes a consumer believe they bought a cheaper 80W laser that is better than a 50W CO2 laser.

Diode lasers

The basis of a solid-state diode laser is a laser diode. Laser diodes can have various values of the emission wavelength. Most of them have 405 nm – 808 nm. The laser diodes usually have TO3, TO5, TO9, TO18 housing.

What makes them different is their sizes.

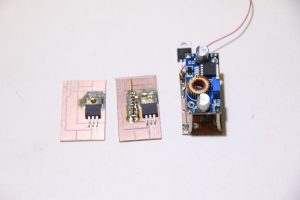

A laser diode needs a laser driver.

A good laser driver is a vital component for the laser lifetime.

These diodes are very sensitive to the initial voltage and current.

Every type of diode needs its type of driver. For example, the driver from NUBM44 or NUBM47 will not work for the M140 diode. A high-quality laser driver is able to stabilize current and maintain constant values of the current and voltage going directly to the diode.

All about diode laser components – laser diodes, electronics, datasheet.

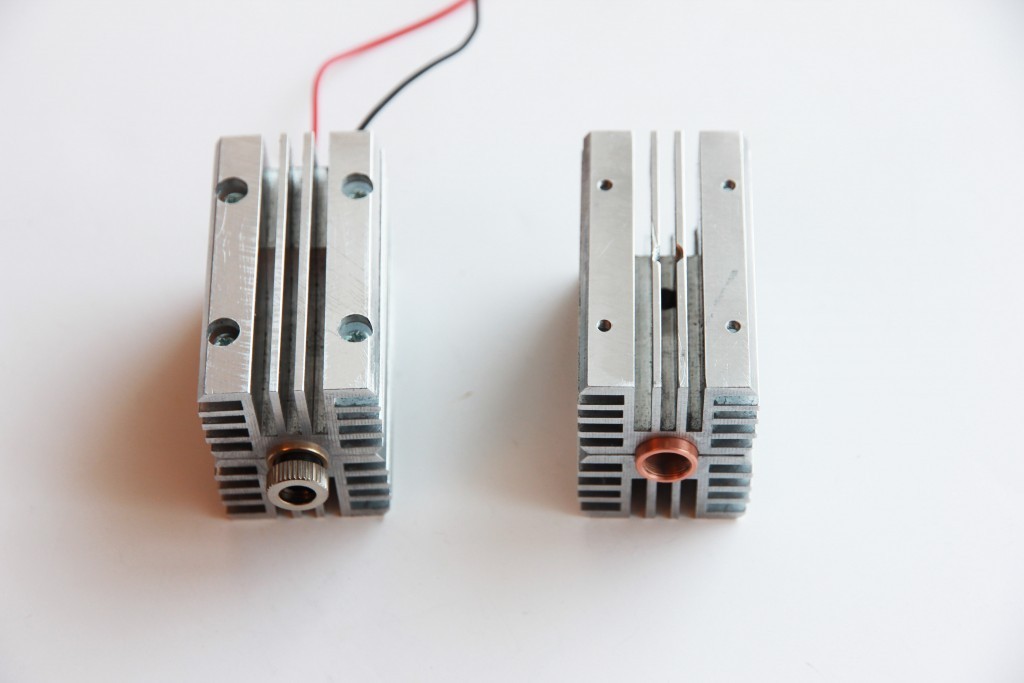

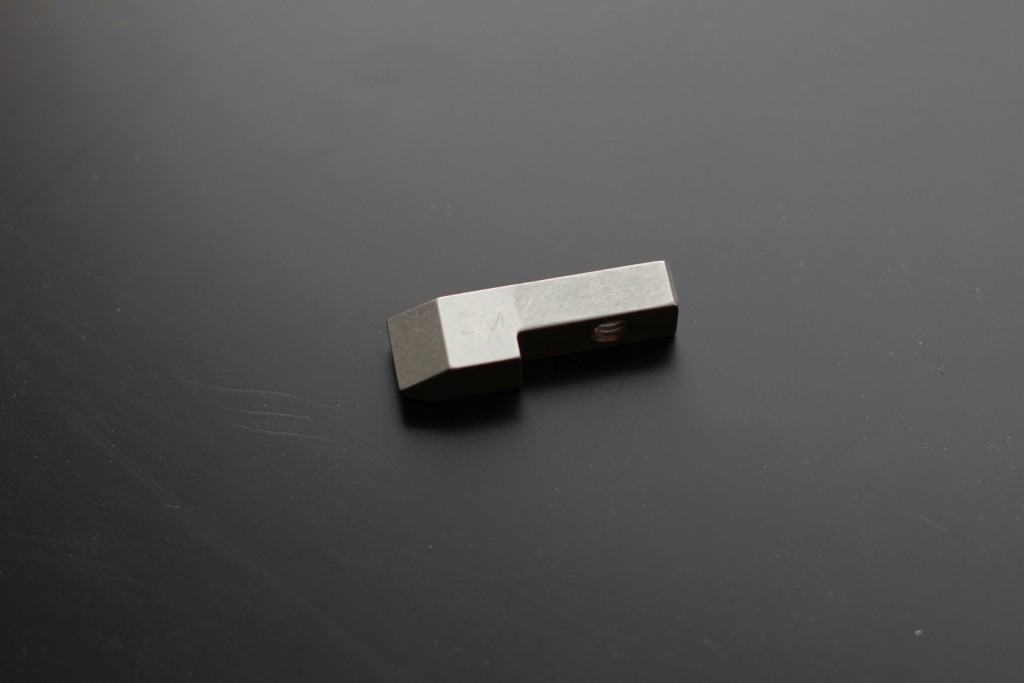

Another important thing is the cooling of the laser diode. As a rule, laser diodes are installed in copper modules like this.

But this copper module is yet unable to effectively give off the heat generated by the diode if the power of the diode exceeds 0.5 watt (500 mW).

It requires an additional heatsink.

The copper laser module can be inserted into a heatsink like this.

Testing and measuring laser power using a calorimeter

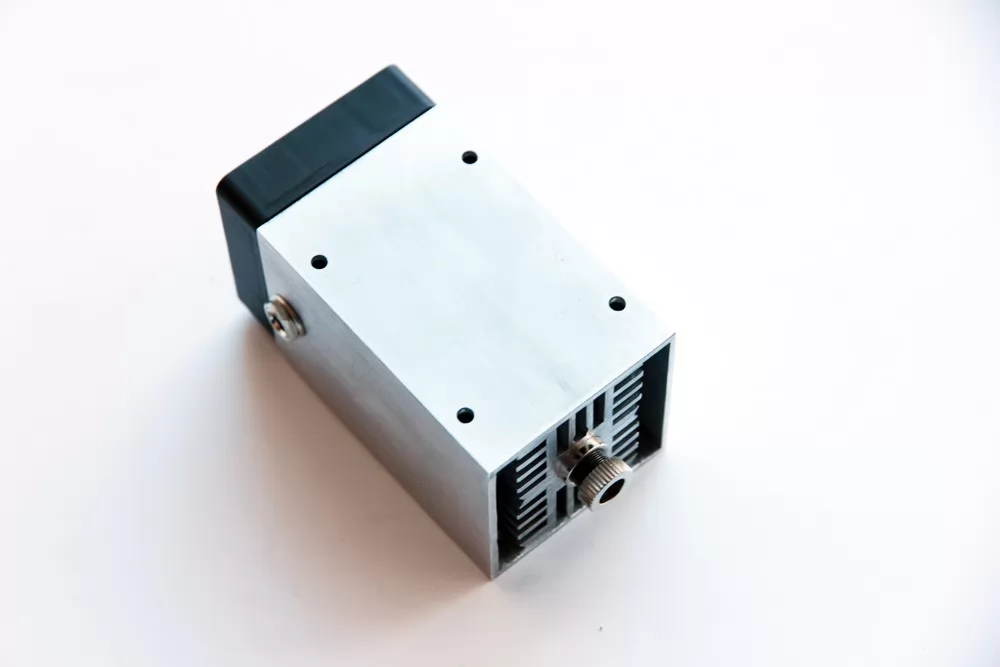

Special aluminum laser heatsink by Endurance production

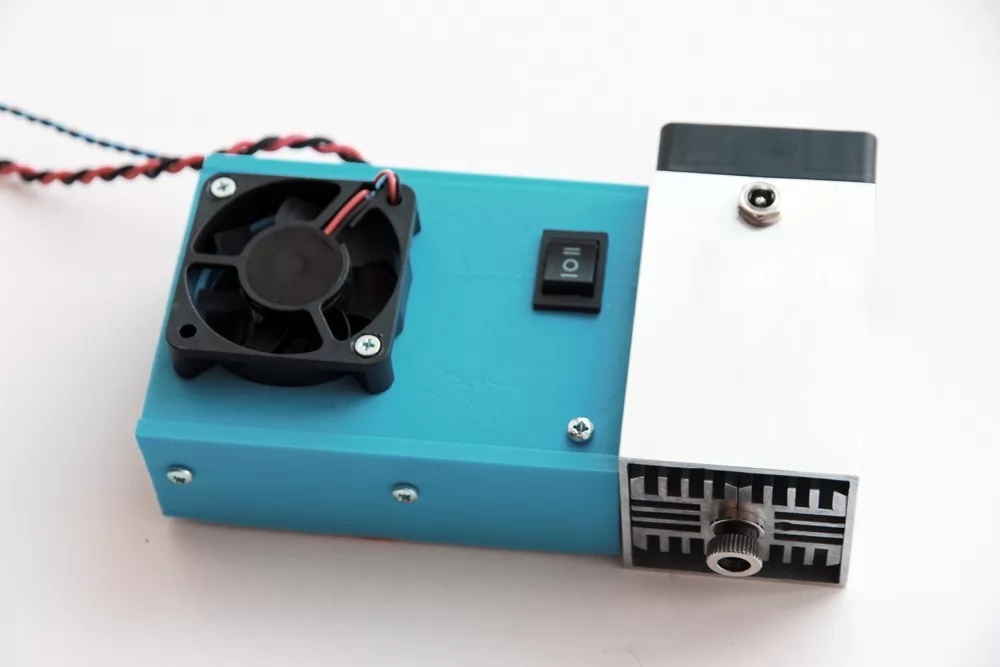

But even inside a copper laser module inserted into a better heatsink, the diode can still generate too much heat, that is why additional air cooling with, let’s say, a regular fan of 40 x 40 mm or 50 x 50 mm in size, is needed to solve the problem.

Cooling of the laser diodes is very important. The cooler the module the longer the lifetime of the laser, the higher the laser power.

The cooler the laser diode the more powerful it is.

When all the basic components

1. laser diode

2. laser driver

3. laser copper housing

4. additional heatsink

are assembled together, it is necessary to choose an optimal focus mechanism for the laser.

Most lasers can operate with 2 types of lenses:

a 3 element long focal lens

or high-quality G2 short focal lens.

The difference between these 2 types of lenses is the focal range. A 3 element lens can have the focus range of 2-10 cm while the focal range of the G2 lens is 2-10 mm (10 times less than the 3 element lens focal range).

The G2 lens is more efficient and is mostly used for laser cutting.

The final thing to do after the laser focusing mechanism selection is encasing of the entire laser module.

The laser housing should be compatible with 3D printers and CNC machines otherwise the laser will not work with them.

Endurance laser modules do not require additional mounting and fastening tools to be installed.

One may ask, what is so cool about diode lasers comparing to fiber lasers and CO2 lasers.

The key advantage of a diode (solid-state) laser module is its small size and weight (about 200 grams or about ½’’). Its small size makes it possible to install the laser-like this almost on any 3D printer or CNC machine.

The diode laser does not require any additional power supply source (12V and 7-8 amps power is max what it needs). This is another important advantage of the diode laser.

The small size and compatibility of the Endurance diode lasers with most 3D printers or XY plotters make the diode lasers a great tool for laser enthusiasts, hobbyists, and makers.

Skeptics might say that CO2 40W laser tubes have the same price as 8 watt or 10 watt diode lasers.

But a high-quality CO2 tube with 40W-60W output will be more expensive rather than to what people think considering a purchase on Aliexpress or eBay.

Another disadvantage of these tubes is their fragility and big size. You cannot install any of them on a 3D printer or CNC machine.

CO2 tubes are compatible only with special plotters that also require special power drivers. Besides, it is important to bear in mind that the power consumption of a CO2 laser machine is much greater than that of a diode laser machine.

As for fiber lasers, they simply do not have separate modules that can be attached to a current chassis. A 10 watt – 20 watt fiber laser machine will probably cost something like 10-15K USD which is dozens of times higher than the price of a diode laser machine.

Of course, fiber laser machines have a lot of advantages in comparison with CO2 and diode laser machines. This is expensive industrial equipment, not affordable to beginners and intermediate experienced tech guys.

In conclusion, I’d like to mention that diode (solid-state) lasers have great potential and are a perfect solution for those who wish to upgrade and bring extensions to their 3D printers or CNC machines.

A lot of nice things such as: photo-engravings and engraving on metal can be done with 8 watt, 10 watt lasers with 445 nm wavelength.

Everything you need to know about the laser

Online skype interview to 3DprinterChat.com

The versatility of a diode laser makes it a favorite choice. Diodes are not limited by abilities and they can be applied for business, DIY crafting and hobby’s, and much more. Endurance lasers have a wide range of lasers that are great for various projects with the range of power that they can emit to engrave and cut on various materials. The distinct features of an Endurance laser are the durable structure design, integration of the efficient driver, stable interconnected parts, cooling system, and power supply and powerful front-end beam output, efficiency, good beam quality, and stable performance for a better laser engraving experience.

Diode laser works well with various DIY projects and they are often user-friendly. If you’re looking for precision and have the correct parameters to set up optimization profiles for each job diode lasers can be a very good choice for your projects.

Real-time advice

We assist and give advice by Phone / Email / Facebook messenger / Telegram / Whatsapp / Viber.

Professional support

We help to install and tune the laser. We offer qualified after-sales support.

Everything you need

We ship everything you need in one parcel to get started.

Immediate delivery

We ship all units within 4-24 hours. DHL express delivery allows you to get the package in 3-5 days.

Lifetime warranty

All our lasers are tested and could work up to 10000 hours.

Upgrade option

Do you have an old model? Upgrade your unit with more powerful one.