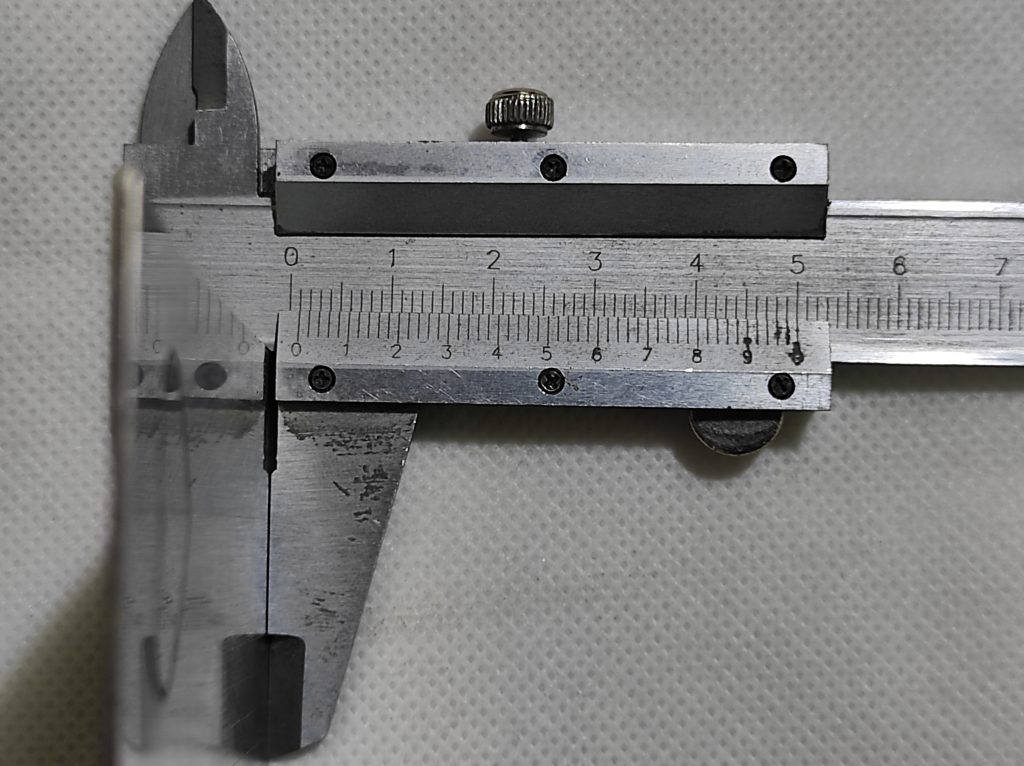

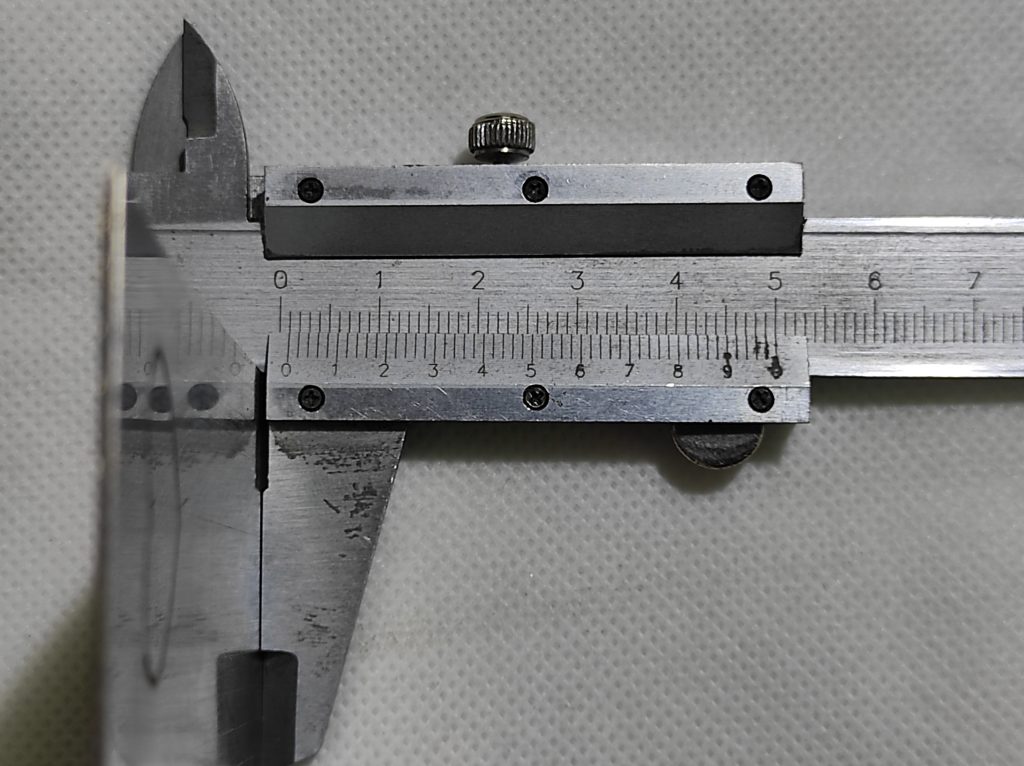

A strange effect was noticed while trying to cut a 1 mm piece of stainless steel with multi passes.

We tried to cut with multi passes (7-10) at speed of 50 mm / min.

We used a 10 watt DPSS 1064 nm Nd:YAG laser with a focal beam spot of 40 uM.

An Endurance 10 watt DPSS (impulse, Nd:YAG) 1064 nm (NIR) laser attachment.

An Endurance air nozzle for a DPSS or fiber laser module

Hailea air compressor (ACO-500)

- Hailea ACO-500 AC Air Compressor Pumps Power :- 500 W

- Pressure :- 0.045 Mpa

- Output :- 275 L/min

- Noise :- <60dB

- Weight :- 8.6 kg

At the end, we could not cut a piece of stainless steel but there was an embossed heart share on the opposite side.

https://www.facebook.com/george.fomitchev/videos/2646419139001715/

Explanation

A DPSS laser has short pulses 7-10 nm, since it generates nanosecond pulses (short pulses) they are usually not used for cutting, since when they interact with the sample surface, a plasma is generated that absorbs the radiation energy without passing it to the sample. The rapidly expanding plasma acts as a reactive force on the metal, and therefore depressions appear. Very powerful pulses can even spall metal on the back. But for this, they use especially powerful lasers.

For cutting metal, either continuous radiation or long pulse mode is usually used. Such radiation melts the metal but poorly removes it from the cut zone. Therefore, blowing with air or other gas is used to remove the melt. In some cases, reactive forces can be used to remove the melt. This is such an intermediate mode when the pulse is not short enough to form a dense plasma, but also not long enough, otherwise, there will be weak reactive forces. But such a regime is not economically profitable, therefore, in practice, as far as I know, it is not applied.