In my previous article, I described a vast field of potential applications of diode lasers.

As they are getting more affordable their popularity among makers and hobbyists is growing. A pretty decent laser for engraving costs around $200, while to do laser cutting you must be ready to open your wallet wider. The price range will be 300-1000 USD for a single multimode diode laser head.

Most diode lasers work in a CW mode and have 7-8 watt power output, while in an impulse mode the peak power can be reached at 10 watt which is quite good but then the average power will decrease down to 2-3 watt.

Most diode lasers have certain limitations.

Multi-mode lasers suffer from a high beam divergence, which can reach as much as 90 degrees.

One more drawback is problematic focusing. Instead of a dot, you have spotted, since diode lasers have fast and slow axes.

Another limitation is a wavelength – the most powerful diodes have 445 nm wavelength or 808 nm.

So, there are no other powerful diodes on the market with more than 5 watt CW power.

If you hear that someone has a 15 or 17 or even 20 watt diode laser, don’t take the bait, it’s fake (https://endurancelasers.com/my-experience-with-non-branded-chinese-made-lasers/)

Summing up, we can’t but ask a very important question:

what is an alternative for a diode laser?

Well, the most anticipated answer is a Co2 tube and a Co2 laser. Unfortunately, you cannot use a Co2 tube with your CNC router, XY plotter or a 3D Printer.

A Co2 tube is very fragile, bulky, requires 10kV power supply and can be only used in a special enclosure.

Undoubtedly, these devices have a great many positive features. You may check this post out >>>

Many of you might already know that the first laser was built on the basis of a ruby crystal pumped with a flash lamp to generate laser radiation, and it was called a solid-state laser.

Solid-state laser characteristics had remained the same for almost 30 years since the first laser creation until 2000’s when flash lamps were replaced with LED (diodes) and ruby crystals were substituted with other rare-earth-doped elements.

Learn more about different laser crystals >>>

That opened a completely new trajectory for DPSS laser modules.

Recently fiber lasers have been gaining momentum and are about to defeat DPSS counterparts. Actually, fiber lasers are also DPSS since their glass fiber is doped with rare-earth ions that make laser generation possible.

But let’s have a close look at DPSS lasers.

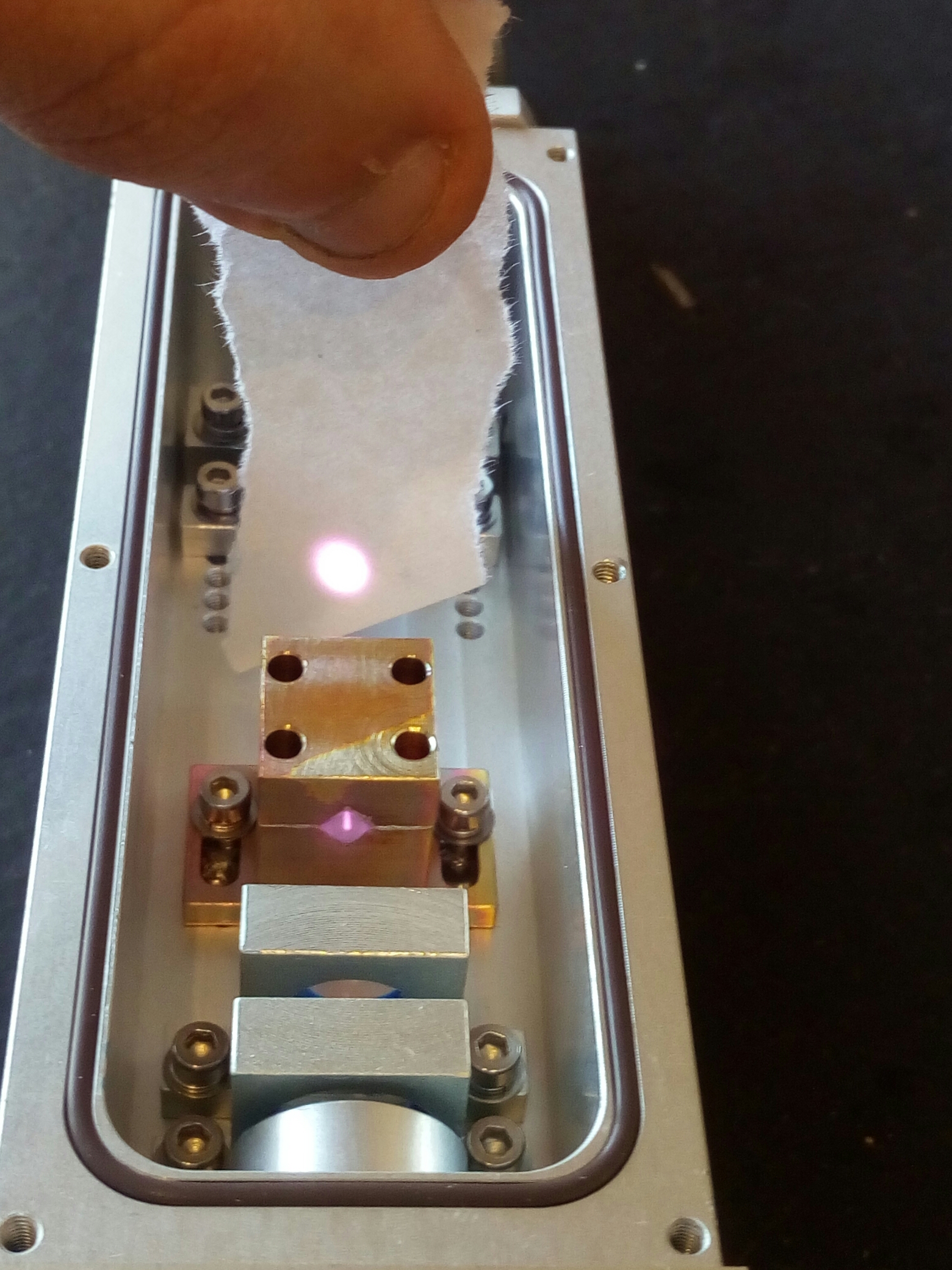

To build a laser resonator one needs to have deep knowledge and high-precision equipment, but in general, the technology basic principles are quite simple and well described.

All you need to know about DPSS Nd:YAG 1064 nm laser modules.

So, what is so cool about DPSS laser modules?

First of all, it’s their pretty high average power. While a DPSS laser can reach 10 watt in a Cw mode and 50-60 kW in impulse, fiber lasers average power is as much as 30-50 watt with a peak of 7-8 kW, which is quite good for metal engraving and metal cutting.

They operate mostly in a non-visible spectrum, it’s around 1064 /1080 nm.

Today almost all lasers of a DPSS or fiber type are used with galvo mirrors. That increases the engraving speed and accuracy but reduces the working area size.

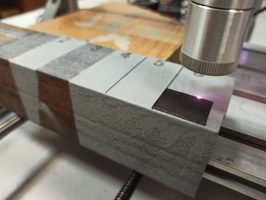

We think that DPSS lasers can be easily installed on any 3D printer, CNC router or XY plotter for metal marking and metal cutting.

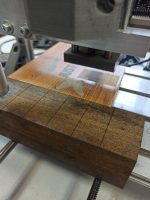

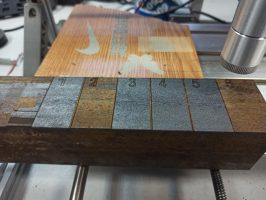

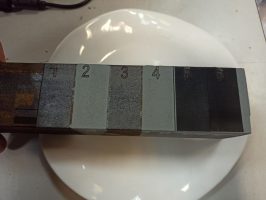

For example, with a 10 watt DPSS laser, you can easily cut up to 0.5 mm of steel, aluminum, brass, and copper.

The reason why DPSS lasers are able to cut metal and engrave without the use of any paste lies in high-energy pulses. The high energy of the pulses interacts with molecules and atoms of metals vaporizing them.

Some 6-8 watt diodes with the same average power cannot even engrave on metals.

Pulses make all the difference. The laser resonator accumulates energy for a certain period of time before releasing it. That makes DPSS lasers operate in an impulse mode. However, the frequency of the pulses can reach 20-30 kHz that is why sometimes they are called quasi-CW.

The beam quality is one more positive feature of DPSS lasers. It is much better than that of other lasers. The DPSS laser beam can be focused on a really tiny spot, as small as 40-60 microns. This feature enables to make of accurate engravings with fine detailing.

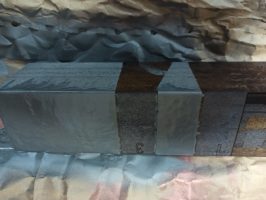

DPSS lasers can also be used for other purposes such as rust removal, for example.

Laser rust removal process

Another application of a 1064 nm infrared laser is toner removal.

That will help save trees and reduce the greenhouse effect.

In my opinion, DPSS laser modules are very much underestimated as useful accessories for 3D printers / CNC machines and XY plotters.

First and foremost, DPSS laser modules are very good for metal engraving and metal cutting, as well as for processing other materials, such as plastics, stone, acrylic, etc. As for transparent materials, lasers with (укажи длину волны) this wavelength cannot engrave or cut transparent glass or acrylic.

I also believe that laser soldering and laser welding might open a great new market pretty soon.

More experiments: laser engravings were done using a 10 watt DPSS laser module

What you can do with a 1064 nm DPSS impulse Nd:YAG laser module