Challenge: To remove toner that has been laser-printed onto plain paper.

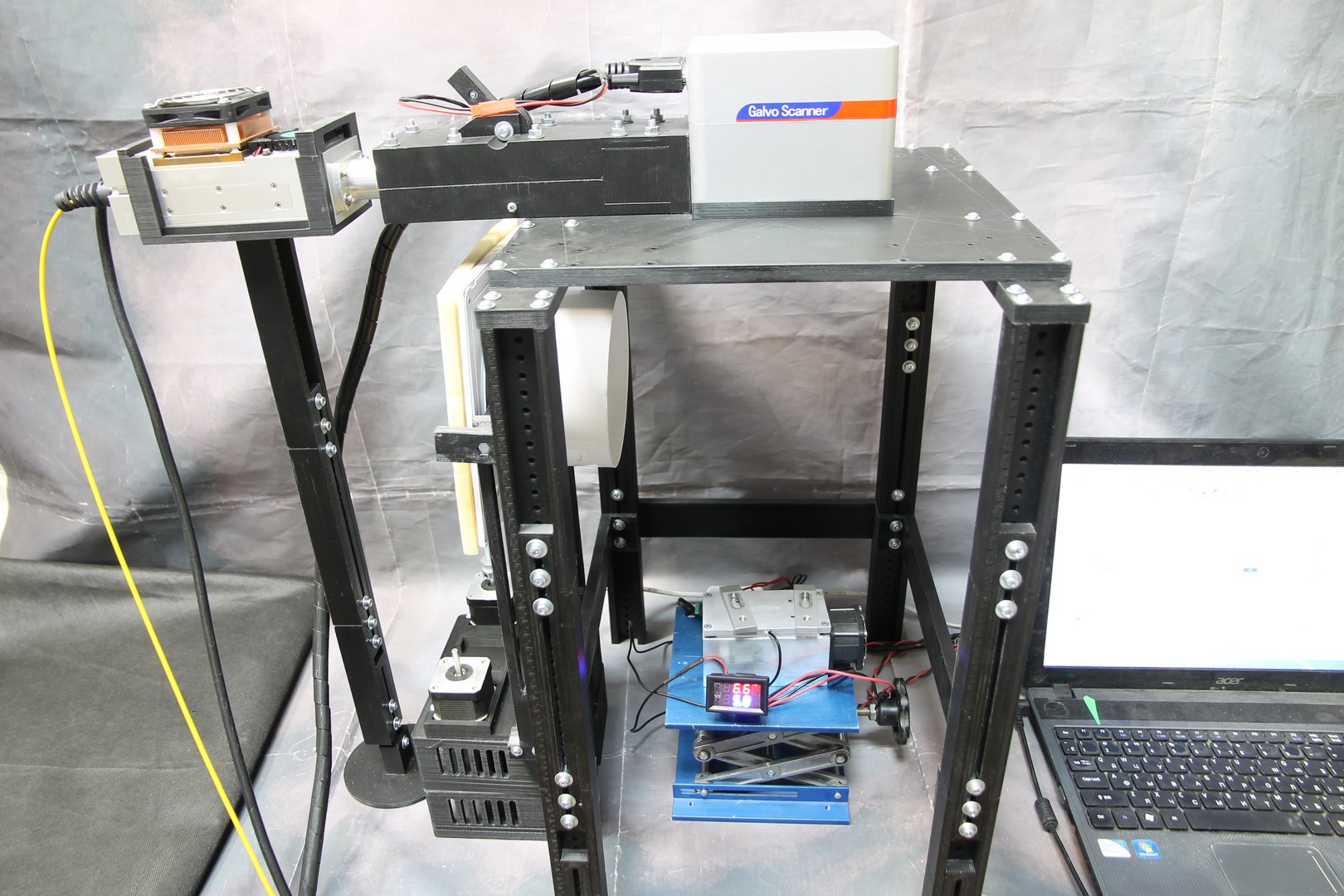

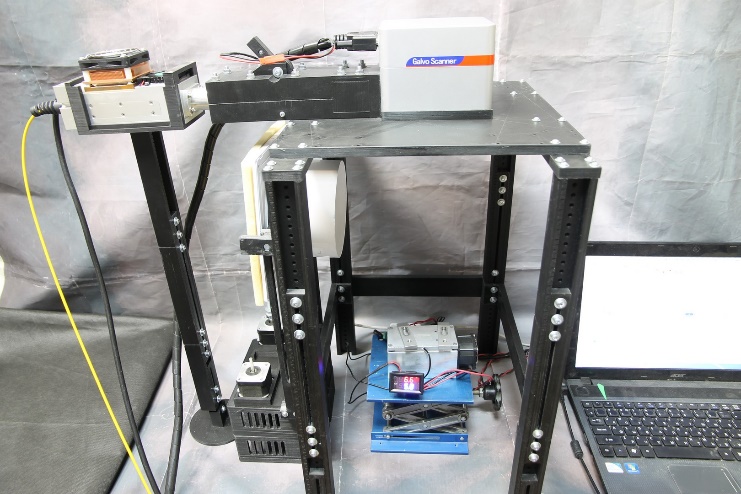

Used equipment:

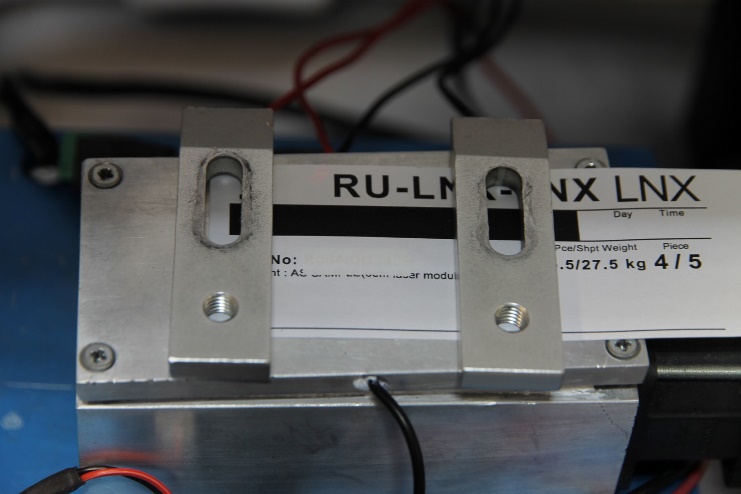

Endurance DPSS laser with a wavelength of 532 nm and a power of 4.5 W.

Galvometer RC1001.

Lens “f-theta lens 532nm f=254” with a working field of 175x175mm.

EzCad control program.

Toner Removal Options:

Laser power – 100%.

Frequency – 20 kHz.

Speed – 800 mm/sec.

Toner Removal Area Shading – Unidirectional, alternating horizontal and vertical.

The distance between hatching lines is -0.05 mm.

Number of passes – 10.

The sample is positioned 8 mm above the focal point.

Sample:

Office paper with a density of 70 g/m2

To increase the efficiency of toner removal, the paper is moistened with isopropyl alcohol before starting the laser.

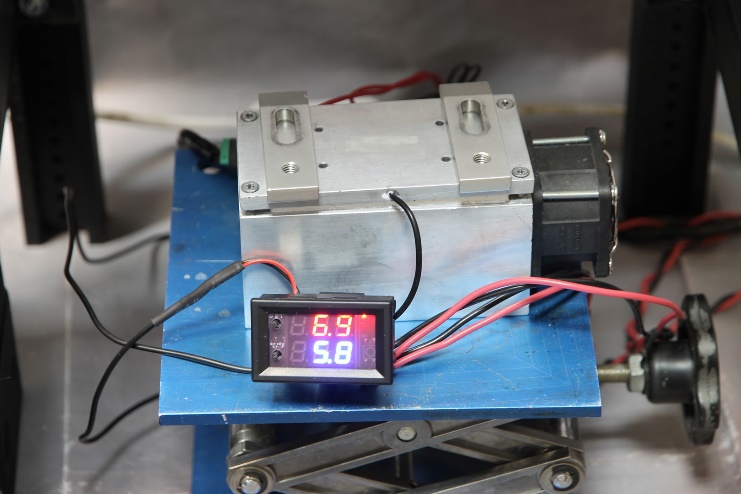

To minimize deformation from isopropyl alcohol, the paper is placed on a cooling platform powered by Peltier elements. The cooling temperature is maintained at around 7 °C by means of a thermostat.

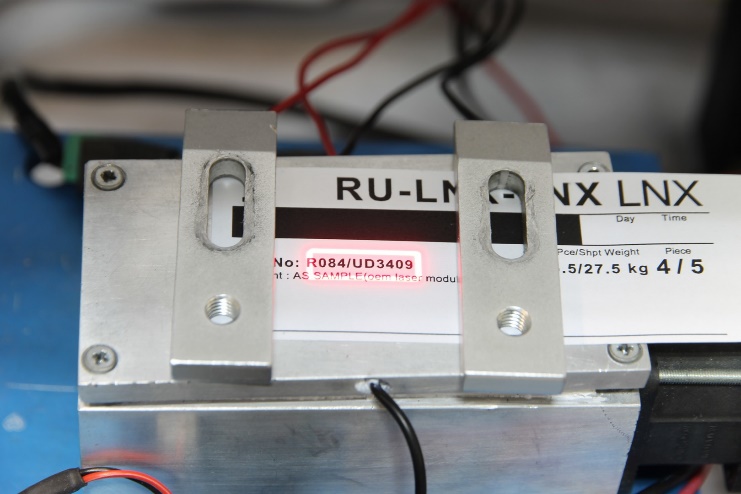

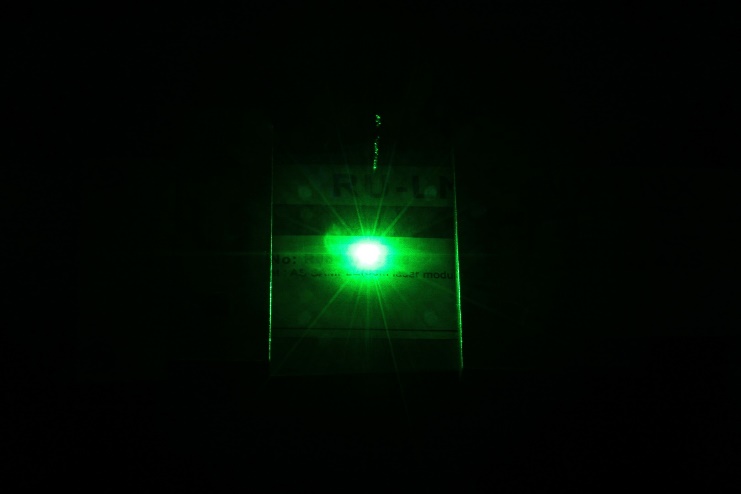

The red “pilot” laser marks the area where the toner has been removed.

Use a cotton swab dipped in isopropyl alcohol to moisten the toner removal area.

Since isopropyl alcohol evaporates rather quickly, the laser starts 1-2 seconds after the paper has been dampened.

After the end of the laser, you must wait 3-5 minutes for the isopropyl alcohol to completely evaporate.

To improve the results of toner removal, the procedure for moistening the paper with isopropyl alcohol and then starting the laser should be repeated three times.

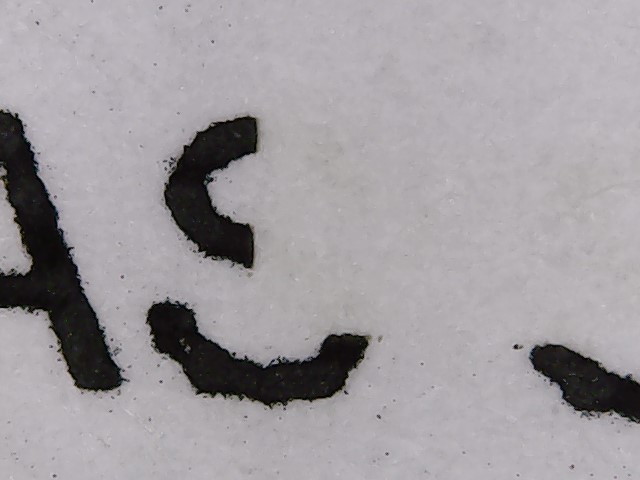

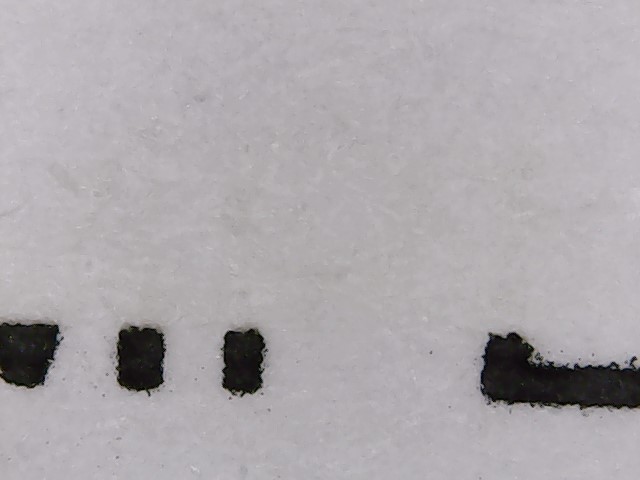

Final result:

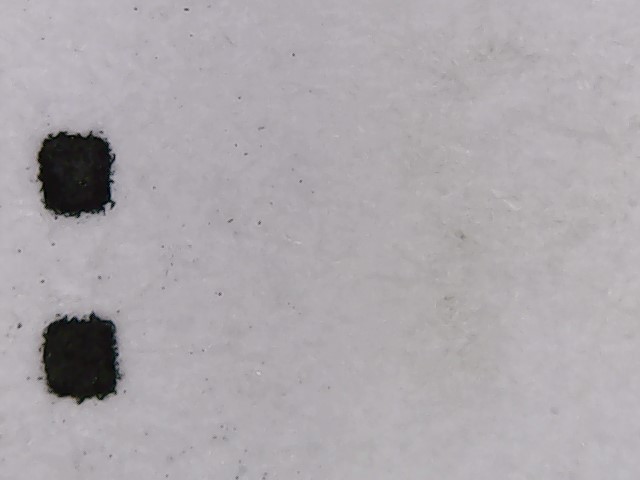

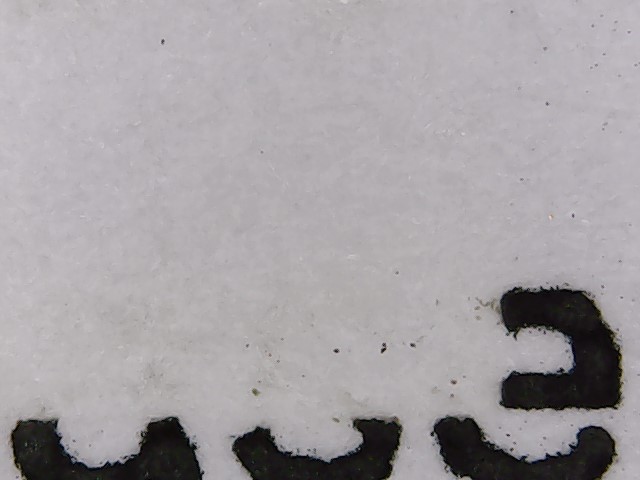

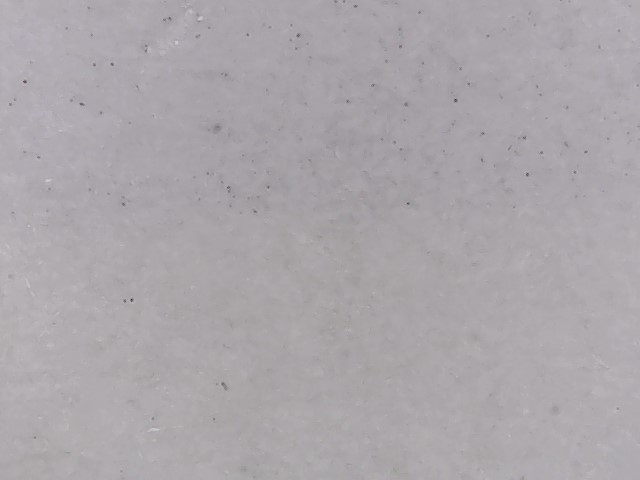

Toner removal area taken with a digital microscope: