What is laser engraving

Laser engraving is a process of patterning materials, such as metal, plastic, acrylic, glass, leather, wood, etc. using a laser beam. Directed to the material, the laser beam evaporates the upper layer of the material surface creating a permanent marking. This process is called ablation.

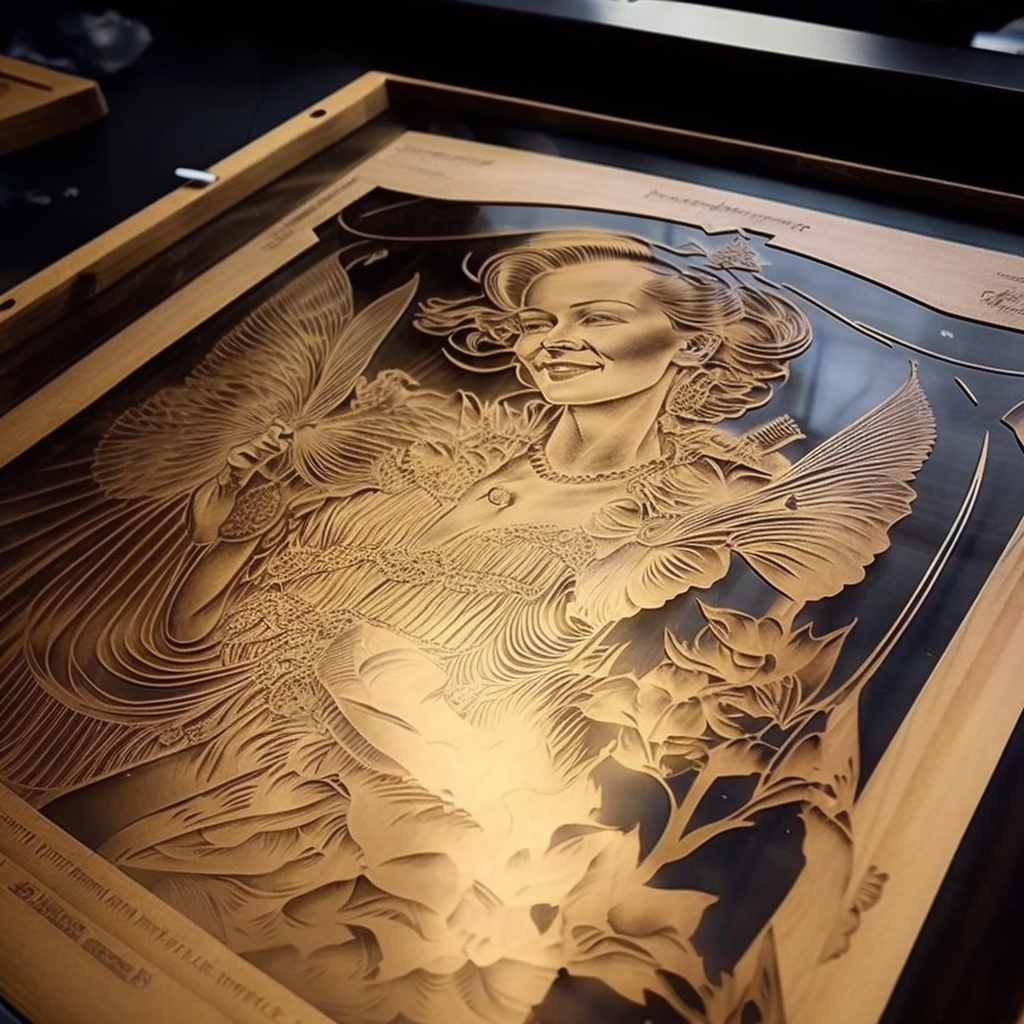

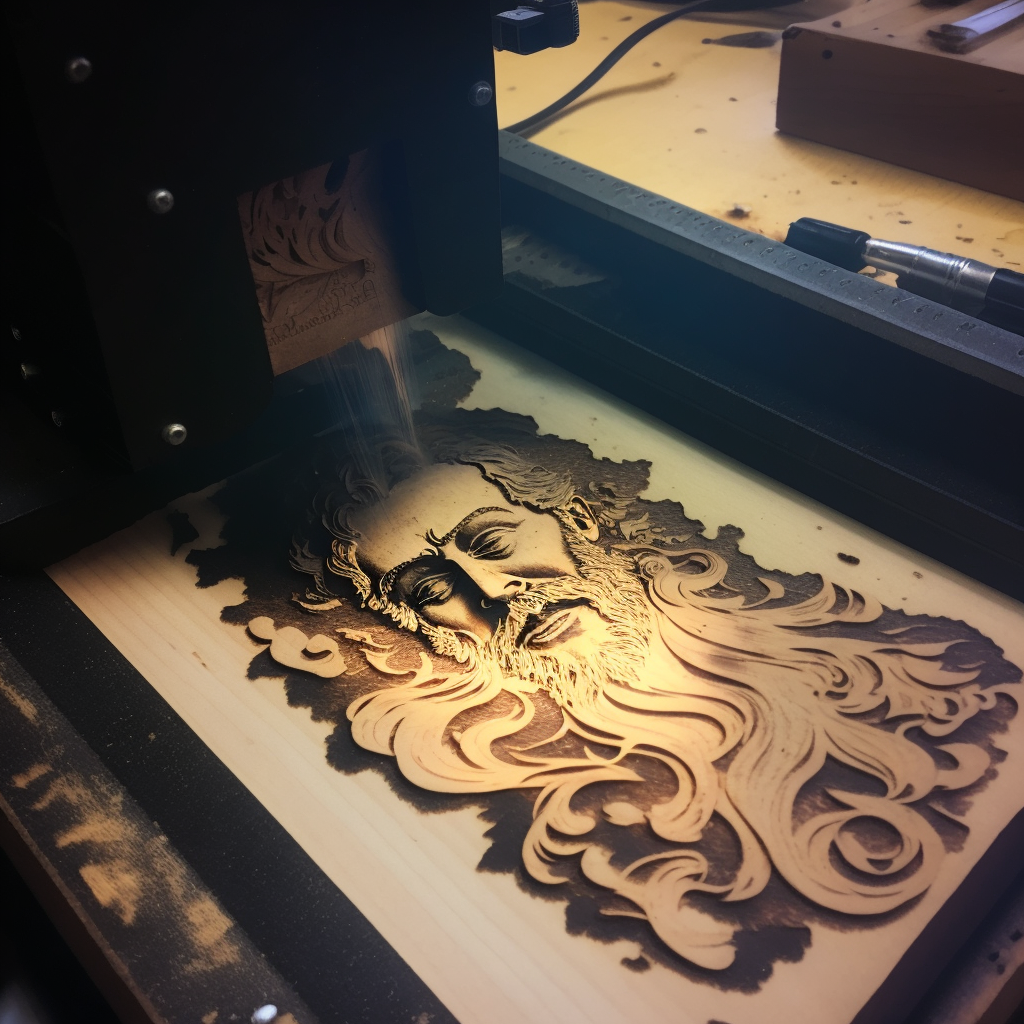

What laser is needed to engrave wood and plywood

A CO2 laser is typically used to engrave wood and plywood. CO2 lasers use a mixture of carbon dioxide, nitrogen, and sometimes helium. Due to the high power, the CO2 laser can easily cut through the layers of plywood to produce a clear and detailed engraving. However, the choice of laser for wood engraving depends on the thickness of the material, desired engraving speed, and complexity of the design. A fiber laser or a YAG laser can also be used to engrave wood and plywood.

What laser can be used to engrave leather

For leather engraving CO2 lasers are usually used. CO2 lasers are versatile and can engrave a wide range of materials, including leather, glass and acrylic. CO2 lasers can make precise and detailed engravings on leather and can also cut it. The choice of the laser for leather engraving depends on the thickness of the material, desired engraving speed, and complexity of the design. However, a fiber laser or a YAG laser may also be used for leather engraving.

What laser is better to use for engraving on glass and acrylic

CO2 lasers are well-suited for engraving on glass and acrylic. CO2 lasers remove the material from the workpiece surface creating a permanent marking. They are ideal for creating awards and trophies, for customizing articles of personal use, such as cell-phone and eye-glass cases, key-chains, pens, etc. The choice of the laser for glass and acrylic engraving depends on the specific requirements for the task at hand. However, a fiber laser or a YAG laser may also be used for glass and acrylic engraving, depending on the application.

Laser paint removal on a glass. Applying non-removable color with the laser.

What laser is better for engraving on steel

For engraving on steel, a fiber laser is often considered the best option. Fiber lasers are good for metal marking due to their high speed, high precision, and deep engraving capabilities. They use a fiber optic cable to deliver the laser beam to the workpiece. It makes them more efficient and cost-effective than other laser types. Fiber lasers can produce high-quality engravings on steel, including stainless steel, and are often used in industries such as automotive, medical, and aerospace. However, the choice of laser for steel engraving depends on the specific requirements, such as the thickness of the steel, desired engraving speed, and complexity of the design. A CO2 laser or a YAG laser can be also used for steel engraving, depending on the application.

What laser is a better choice for engraving on aluminum and titanium

High speed and high precision of fiber lasers, their ability to produce high-quality permanent markings on non-ferrous metals such as aluminum and titanium make them ideal tools for engraving on aluminum and titanium. Fiber lasers are used for product labeling, part marking, and serialization. A CO2 laser or a YAG laser can also be used for aluminum and titanium engraving, depending on the application.

How to make a color metal engraving on stainless steel – all you need to know.

Is it necessary to use a hood for laser engraving?

It is highly recommended to use a hood or some form of ventilation when laser engraving. During the laser engraving process dust, fumes and other products of combustion are often produced, which are harmful if inhaled. The hood or a ventilation system helps remove these by-products of laser engraving, providing a safer environment for the operator and reducing the risk of inhaling harmful substances.

The use of a hood also helps reduce the risk of fire. Some materials such as wood and plastic, can take fire when contacted the laser beam. A hood covering the laser with the workpiece will reduce the risk of fire.

The specific requirements for a hood or ventilation system depend on the type of the laser being used, the materials being engraved, and local regulations and safety codes.

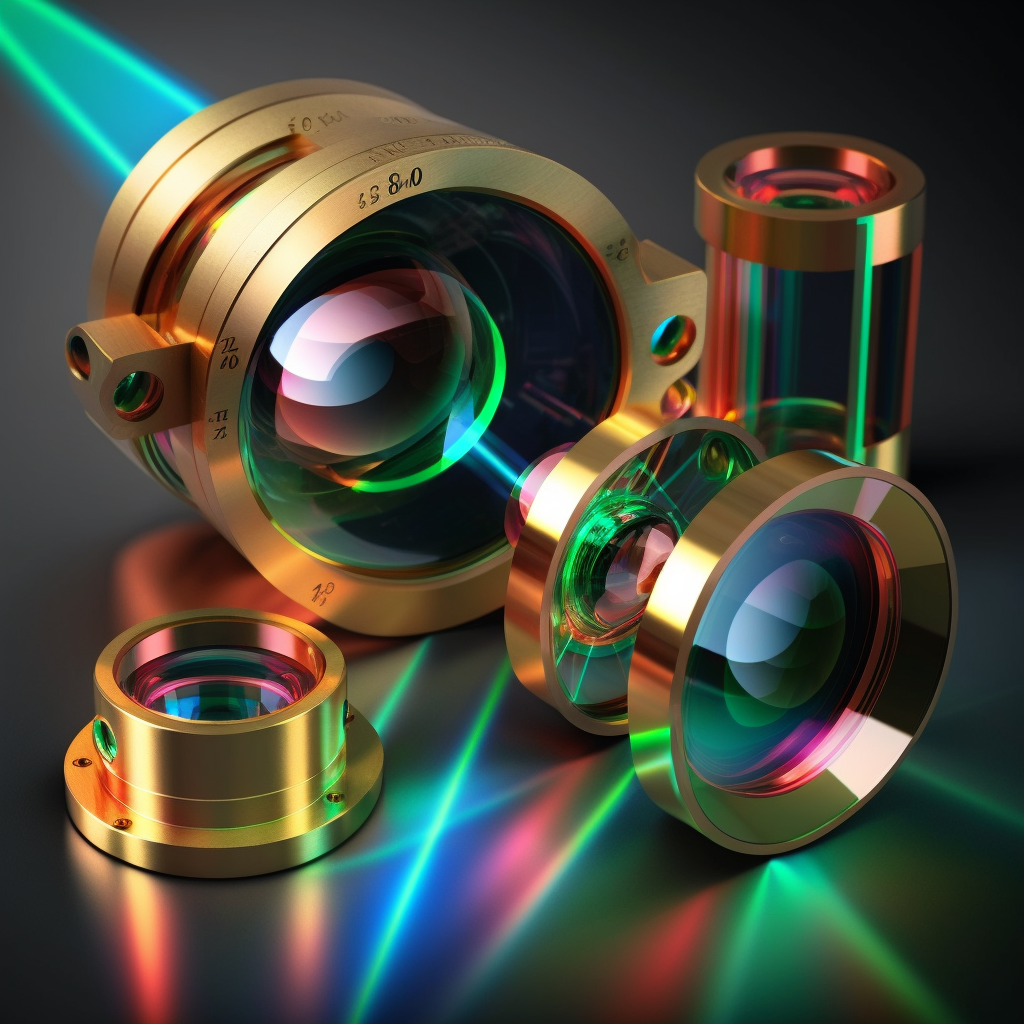

What lenses are used for laser engraving

The type of the lens for laser engraving depends on the workpiece size, laser power, and the desired depth of the engraving. Commonly used lenses for laser engraving are as follows:

- ZnSe lenses:

ZnSe lenses are made of zinc selenide and are used in CO2 laser systems. They are the most common type of lens used for laser engraving and are well-suited for engraving on wood, leather, and plastic.

- F-Theta lenses:

F-Theta lenses are used in scanning systems and are designed to produce a flat laser beam that covers a large surface area. They are often used for large format engraving on glass, acrylic, and metal.

- Glass lenses:

Glass lenses are used in both CO2 and fiber laser systems for high-precision engraving on a wide range of materials.

- Reflective lenses:

Reflective lenses increase the laser beam power and are used in CO2 laser systems for deep engraving on metal and stone.

The choice of the lens depends on the specific requirements of the application. Consult with a laser expert or supplier.

Laser lens pack for diode lasers

How much does a universal laser engraver cost

The cost of a universal laser engraver varies greatly depending on several factors such as the type of the laser, its power, the size of the work area, and level of automation. Customization and additional features, such as a larger work area or increased laser power, will also affect the cost of the engraver.

For a basic CO2 laser engraver, the cost ranges from a few thousand dollars to tens of thousands of dollars. For a higher-end fiber laser engraver, the cost can range from tens of thousands of dollars to several hundred thousand dollars.

It is important to carefully consider the specific requirements of the application and to choose a laser engraver that is best-suited to the task at hand. It is also recommended to compare prices and features from several suppliers to ensure the best value for the investment.

What to look for when buying a laser engraver

There are several key factors to consider:

- Type of the laser: The type of the laser is a crucial consideration when buying a laser engraver. CO2 lasers are versatile and can engrave a wide range of materials, while fiber lasers are better suited for metal engraving.

- Power: The power of the laser is another important consideration. A more powerful laser will produce deeper and more precise engravings, but it will also cost more. Consider the thickness of the material to be engraved and the desired depth of the engraving when choosing the laser power.

- Work area: The size of the work area is another important parameter. Choose a laser engraver with a work area large enough to accommodate the workpieces to be engraved.

- Precision: Precision is an important feature to consider when buying a laser engraver. Choose a laser engraver capable of producing precise and detailed engravings.

- Material compatibility: Make sure the laser engraver is compatible with the materials that will be engraved. Thus, CO2 lasers are well-suited for engraving on wood and glass, while fiber lasers are better for engraving on metal.

- Cost: The cost of the laser engraver is important Choose a laser engraver that provides the best value for the investment.

- Maintenance and support: Consider the level of maintenance and support required for the laser engraver. Choose a laser engraver that is backed by a reliable manufacturer and has a good reputation for quality and support.

It is important to carefully consider these factors and choose a laser engraver that fits the specific requirements of its future application best. Consult with a laser expert or supplier to make an informed decision.

All you need to know before buying a laser or an engraving / cutting machine

What programs are used for laser engraving

There are several programs that can be used for laser engraving, including:

- LaserCut: A popular open-source program for controlling laser cutters and engravers.

- CorelDRAW: A widely-used graphics software that can be used for laser engraving, especially for vector graphics.

- LightBurn: A proprietary software specifically designed for laser engraving and cutting, offering advanced features such as vector engraving, raster engraving, and more.

- Inkscape: A free and open-source vector graphics software that can be used for laser engraving, although it may require some additional plugins for full laser control functionality.

- T2Laser: A software specifically designed for laser engraving, offering features such as grayscale image processing, curve smoothing, and more.

- Adobe Illustrator: A widely-used vector graphics software that can be used for laser engraving.

- RDWorks: A software designed specifically for laser engraving, cutting, and marking, with features such as grayscale engraving, vector cutting, and more.

These programs vary in terms of features, ease of use, and compatibility with different laser engraver systems. Consider carefully the specific requirements of the application and choose a software that is best-suited to the task at hand. Software recommendations of the laser engraver manufacturer or supplier based on their product and the specific requirements of the application can be especially useful.

What companies supply the market with laser engravers

There are several companies that supply the market with laser engravers, including:

- Trotec Laser: A leading manufacturer of laser engraving and cutting systems, offering a range of systems for industrial, professional, and personal use.

- Epilog Laser: A provider of laser engravers and cutters, offering systems for both hobbyist and industrial use.

- Boss Laser: A supplier of laser engravers and cutters, offering a range of systems for personal, small business, and industrial use.

- Universal Laser Systems: A provider of laser engravers and cutters, offering systems for both hobbyist and industrial use.

- Han’s Laser: A leading manufacturer of laser engravers and cutters, offering systems for both personal and industrial use.

- Full Spectrum Laser: A provider of laser engravers and cutters, offering systems for both personal and industrial use.

- Laserax: A provider of laser engravers and cutters for industrial use, offering systems for a wide range of applications.

These are just a few examples of companies that supply the market with laser engravers. There are many more suppliers and manufacturers of laser engravers.