Initial task

Perform scribing with a depth of at least 0.35 mm, so that it is possible to break the material along the scribing cut.

For a rational consumption of the test material, strips ~7 mm wide were cut off from the plate, on which the tests were carried out. All tests were performed at a given laser power of 100%.

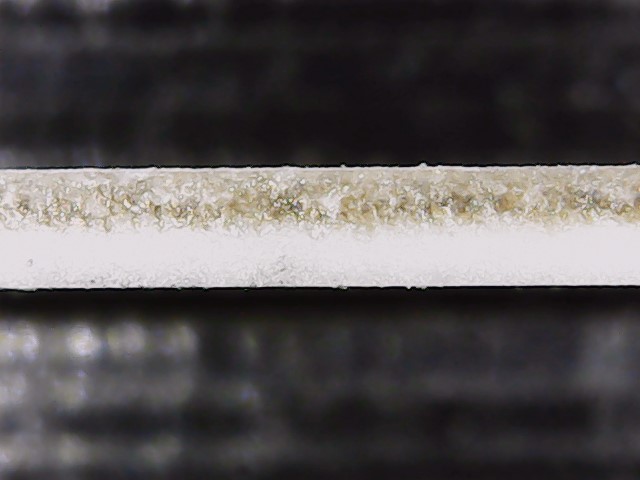

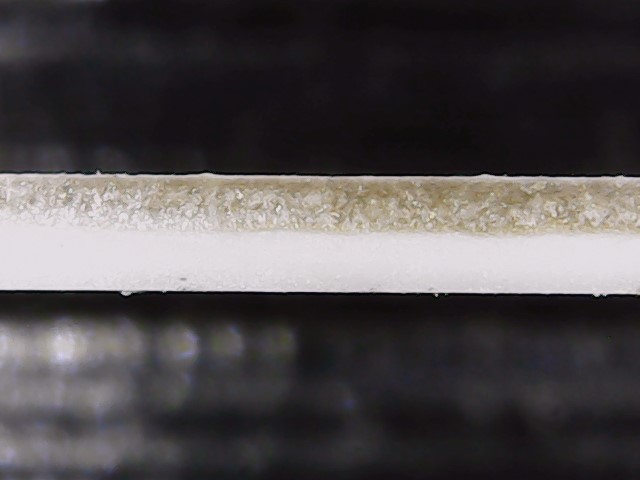

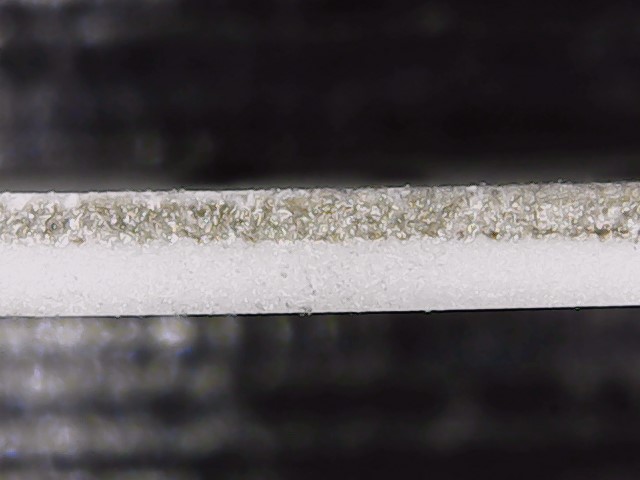

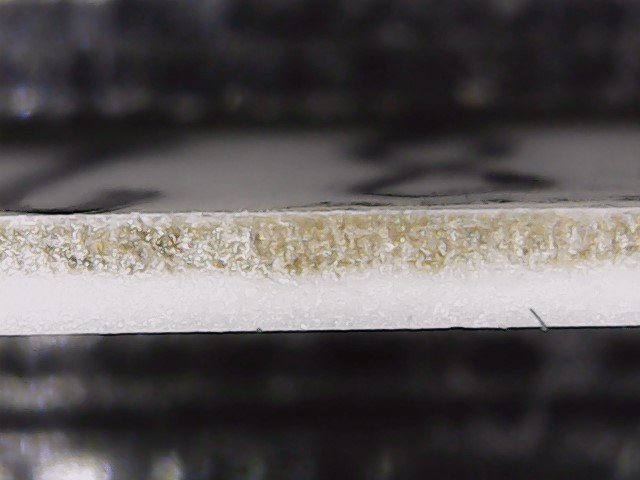

The scribing results were viewed using a digital microscope.

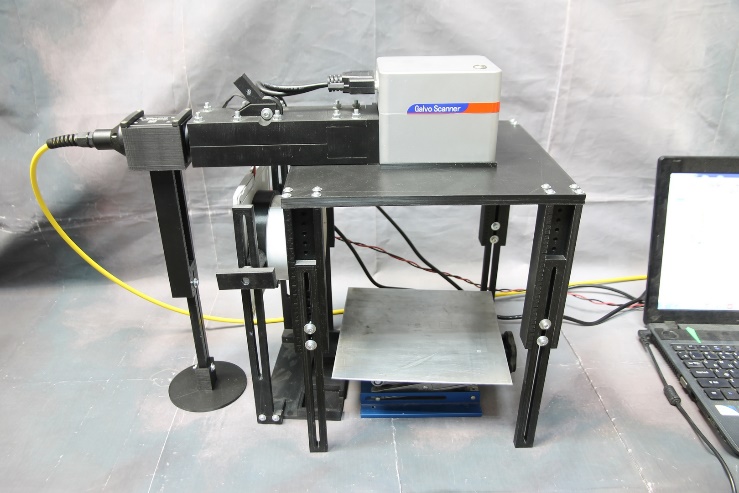

Used equipment:

Wavelength 1064 nm

Power 50W

Pulsation frequency 50-100 kHz.

Energy per pulse 1mJ at 50kHz

Endurance DIY Galvo 3D printed holder

Galvanometer RC1001

F-Theta lens SL-1064-112-163G

Focal length 163 mm

Working field 112×112 mm

EzCad Software

Test material:

Alumina ceramic plate 0.7 mm thick.

Test results

Speed – 200 mm/s; Pulse frequency – 50 kHz; Number of passes – 20

Speed – 200 mm/s; Pulse frequency – 75 kHz; Number of passes – 20

Speed – 200 mm/s; Pulse frequency – 100 kHz; Number of passes – 20

Speed – 300 mm/s; Pulse frequency – 50 kHz; Number of passes – 50

Speed – 300 mm/s; Pulse frequency – 75 kHz; Number of passes – 50

Speed – 300 mm/s; Pulse frequency – 100 kHz; Number of passes – 50

Speed – 400 mm/s; Pulse frequency – 50 kHz; Number of passes – 60

Speed – 400 mm/s; Pulse frequency – 75 kHz; Number of passes – 60

Speed – 400 mm/s; Pulse frequency – 75kHz; Number of passes – 60