On this page, we explain some key points about the laser assembling process and about components that we use.

We do all variety of advanced metalwork.

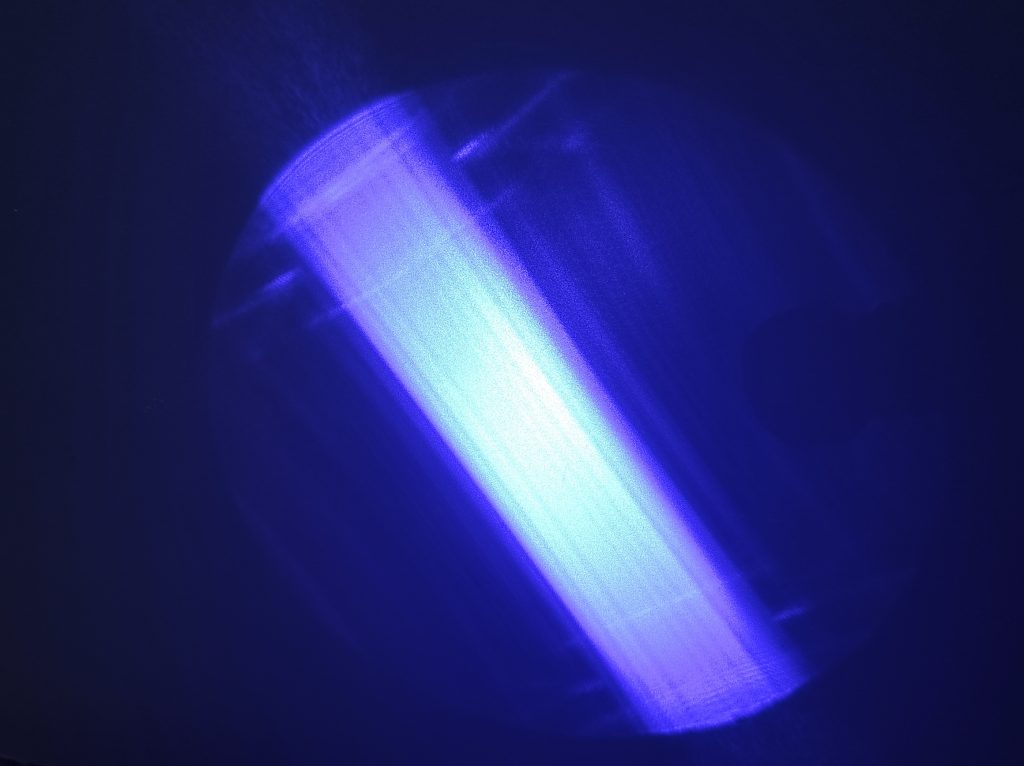

We equip our 8 watt (8000 mW) and 8.5 watt (8500 mW) lasers only with high-quality diode NUBM44 with 445 nm wavelength.

The heart of our 10 watt models including “Invincible” PLUS, Delux and PRO is a high-quality NICHIA NUBM47 laser diode with the 7 watts pure rated power output (CW mode), all of which we check and test before assembling!

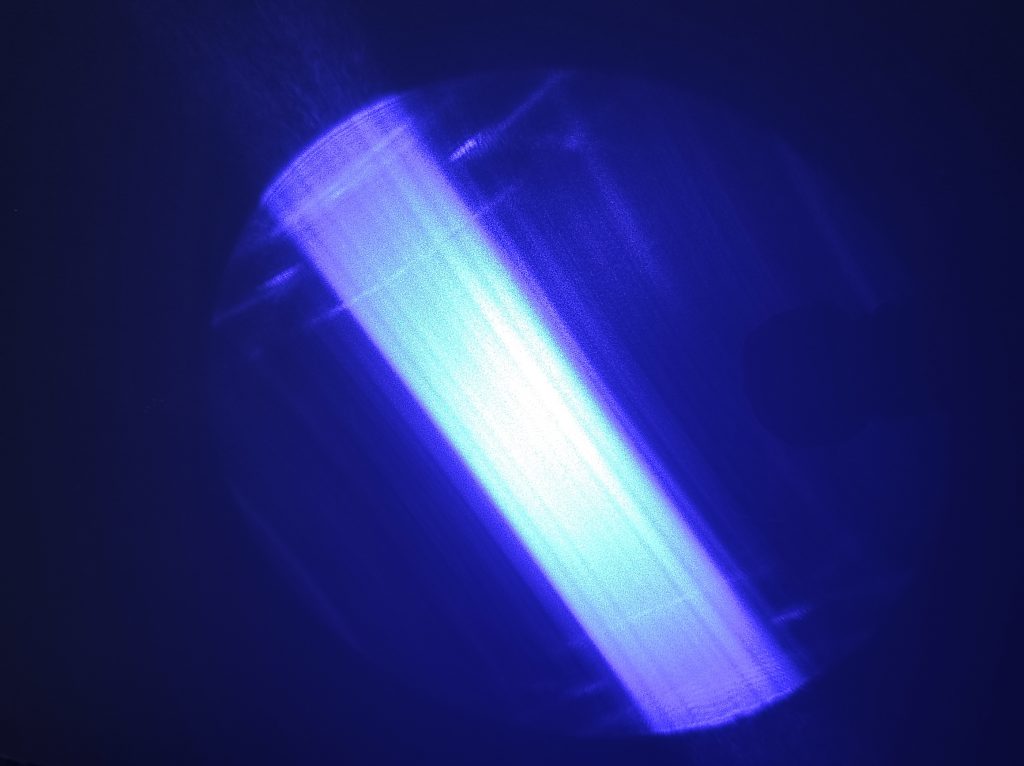

All diodes are being carefully tested every time before the final assembling.

We do final tests before shipping the entire laser module to our customers.

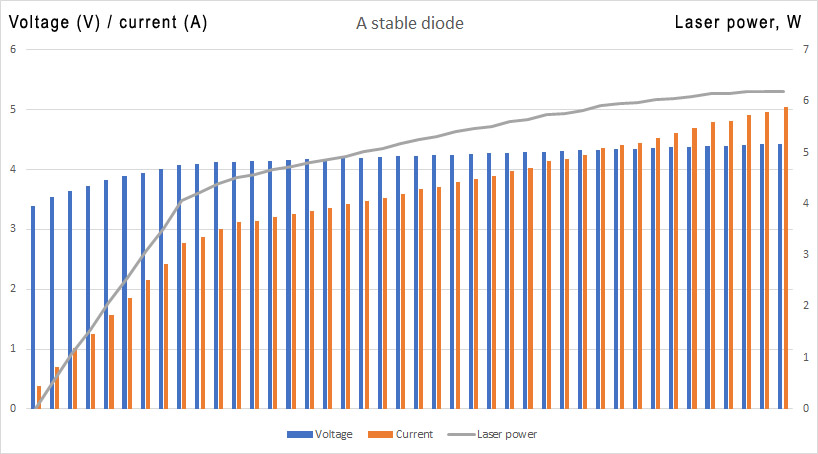

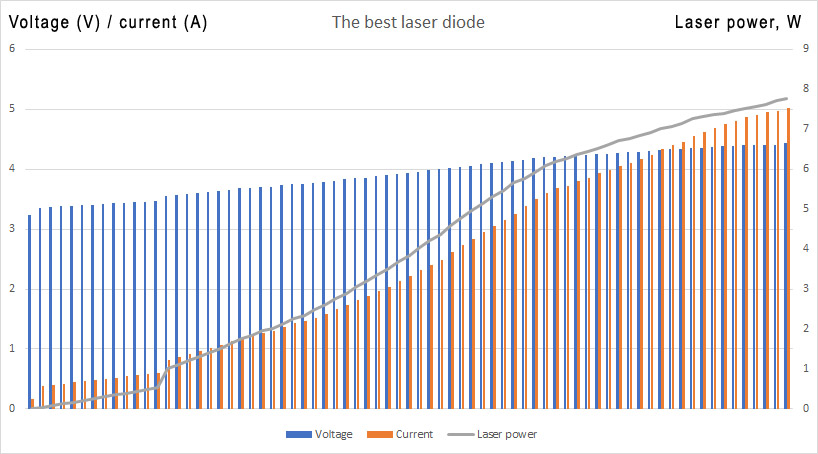

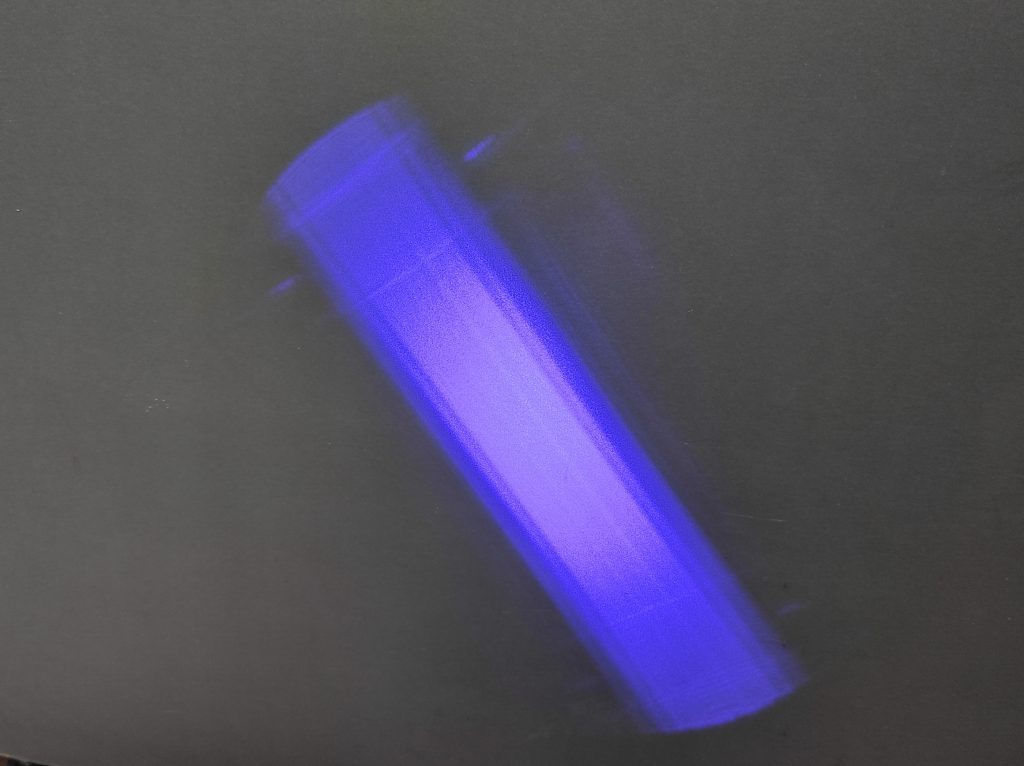

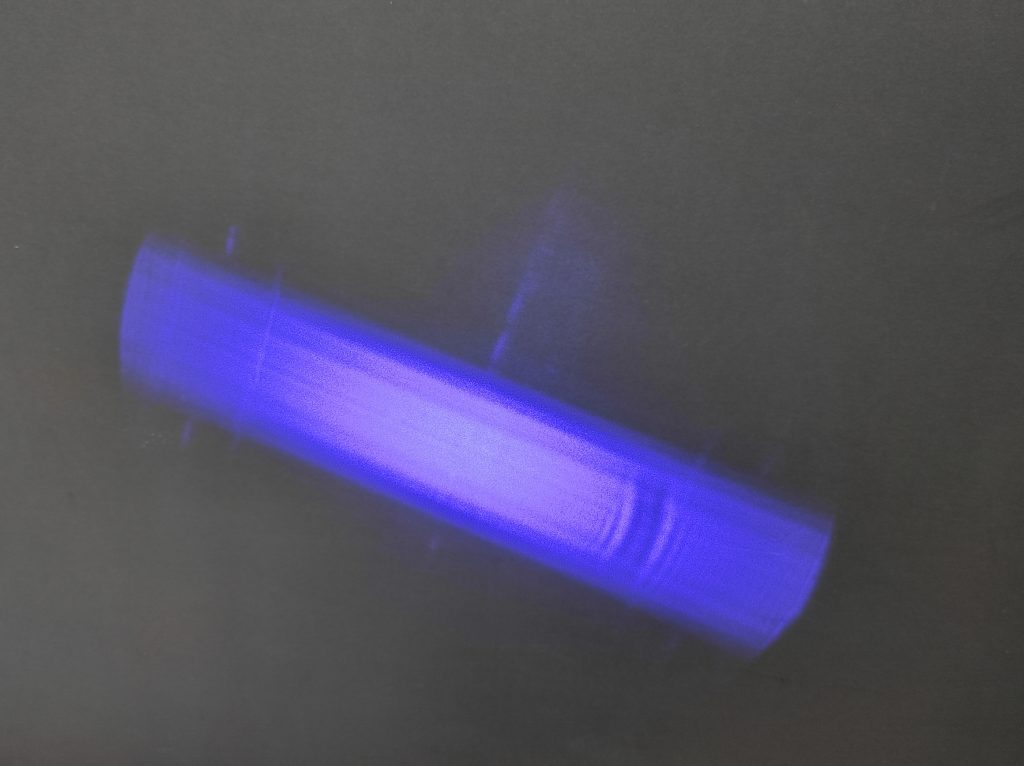

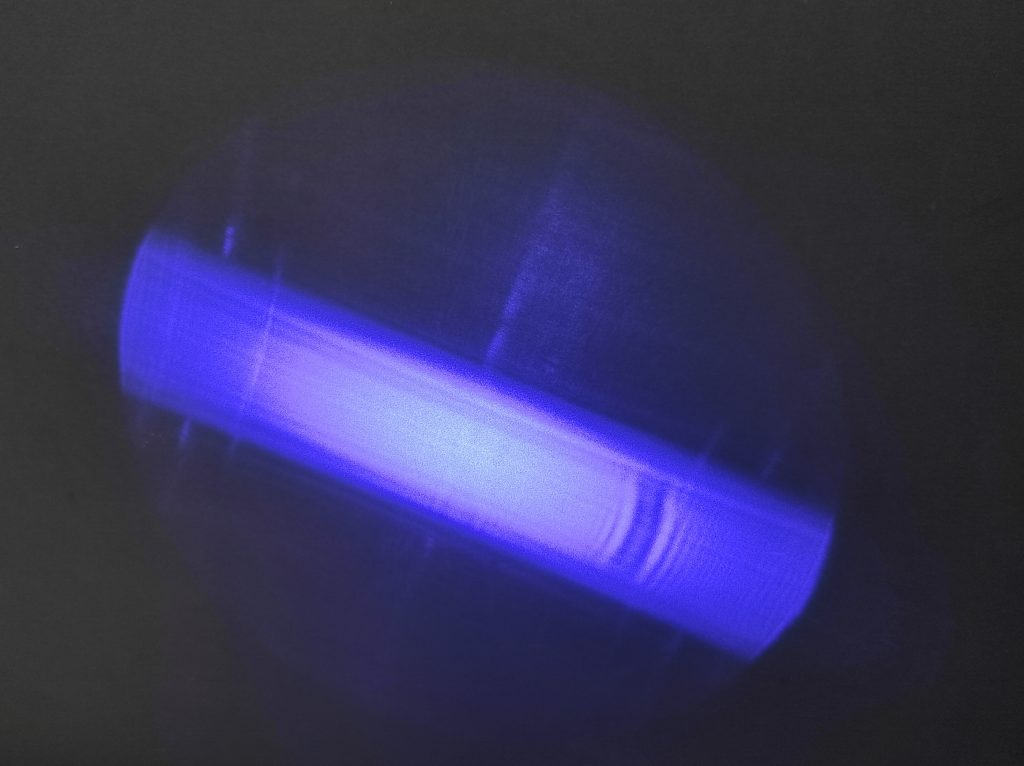

They are well tested before we do laser assembling! An Endurance experimental data for NUBM44 / 47 NICHIA laser diode

Original beam shape

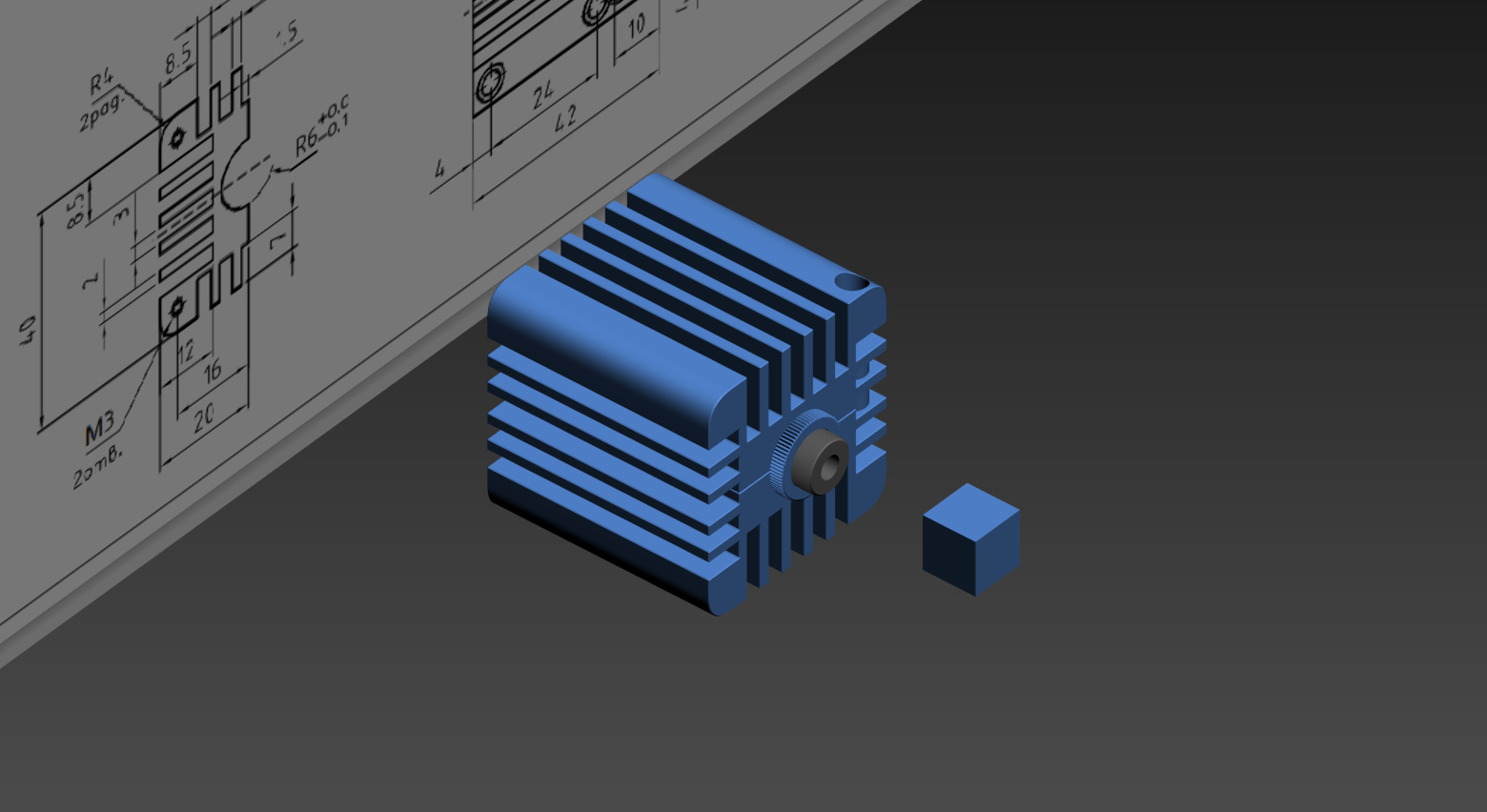

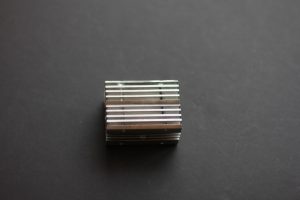

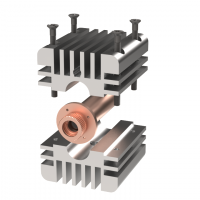

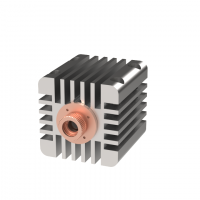

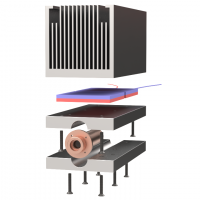

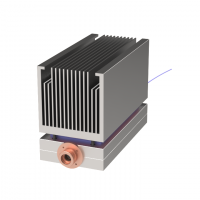

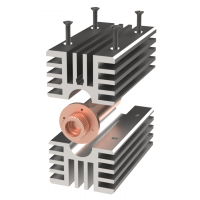

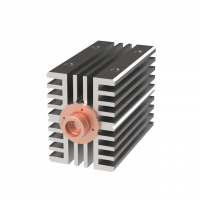

Our proprietary metalwork

Our PLUS version has an extra TEC cooling with an external heatsink that allows keeping diode laser temperature even lower, thereby, our lasers are able to work up to 8000-10000 hours. Their lifetime is 10-100 times longer than that of most of the Chinese analogs and at least 5-10 times more than Co2 average tubes.

All you need to know about diode laser operating temperature:

The importance of removing waste heat created by Laser Diodes. Heat is the biggest cause of field failures, especially for higher power laser diodes. Waste heat must be removed instantaneously, or the laser will be catastrophically damaged or, as a minimum, experience a very much shortened lifetime. Incorporated in Laser Diodes must include heat sensing and removal management.

Determining the amount of waste heat is to take the total input power (Amps*Voltage=Input Power Watts) minus the optical output power (Watts). The balance is the watts of max waste heat. diodes are typically 10 – 60% efficient at converting electricity into light. This heat is generated within a small area, it is critical that the laser is securely connected to an adequate heat sink and quality heat sink compounds should be applied to all press-fit parts. Just like found on your computer cpu’s these parts expand and contract throughout the use of different power settings and pulse changes. For many laser diodes, operating at a temperature lower than recommended can slightly increase the output power (higher efficiency) and/or improve lifetime. This is true not only in Laser Diodes and LED lighting alike.

Heat sinks – Most all laser diode packages will need some sort of heat sinking. The heat sink must be capable of dissipating the waste heat generated by the laser. Lower power devices may only need to be mounted to a base plate, higher power devices will need a more substantial heat sink or a forced air-finned heat sink, and laser diodes arrays (bars) may need active cooling to handle the waste heat. The best heat sink material is copper, but aluminum with heat sink compound is also a suitable heat conductor. Without this, the aluminum metal material is one of the most fluid metals made. It has thru time caused many engine parts to warp, crack and leak and damage engines in every make an automobile.

This also happens in Laser Modules the perfect machine part are green when you get your equipment and are subject to heating and cooling and losing the perfect fit and active cooling becomes less effective. The only way to ensure cooling is with a thermal compound that will keep a fluid bond between all parts and stop any corrosion from happing. An interesting fact is that actively cooled heat sinks offer much better heat sinking performance and introduce a temperature control into the system.

Another alternate to aid in heat dissipation is An indium foil spacer that can be used to reduce the thermal impedance of the laser package to the heatsink interface. Engineering has experienced is that indium foils offer a negligible improvement over a good copper-to-copper interface. Epoxy Technology H21D is used by many it is a silver-filled epoxy it is a “space-qualified” low outgassing compound that avoids contamination of the laser. very small thermocouples can be used to check the temperatures between the laser and the heat sink. Another test for the heat sink configuration is to check the laser emission wavelength at the specified current and operating temperature. A much longer wavelength than specified on the data supplied with the laser indicates bad thermal contact and thermal overload of the diode laser.

Be aware They require a special set of specifically designed electronic control elements. This set of control elements are combined to produce what is commonly called a laser diode driver or laser diode current source. Essentially, these elements determine how the laser is turned on and driven to produce a specific wavelength and output power. And how this is accomplished without damaging the laser diode most of the time.

Fact Node

There is a lot of detailed information about laser diodes online. But in short, a laser diode is a semiconductor device made of two different materials. One a P-material, the other an N-material, sandwiched together. Forward electrical bias across the P-N junction causes the respective holes and electrons from opposite sides of the junction to combine giving off a photon in the process of each combination. The junction area’s surfaces (cavity) are to a mirror-like finish. Those who know laser theory know what happens when there are photons bouncing around a polished cavity. The electrical bias for the junction needs to be a stable, low-noise, transient free current source. Laser diodes are current-driven and current-sensitive semiconductors. A change in drive current equals a change in the devices’ wavelength and output power.

We only use original NICHIA LD (laser diodes)

Keep in mind that True Nichia LD have a bar code

All our lasers are handmade and individually tested, which makes for their quality and reliability assurance.

Laser diodes datasheet for 8 watt / 8.5 watt / 10 watt / 10 watt+ / 20 watt laser modules

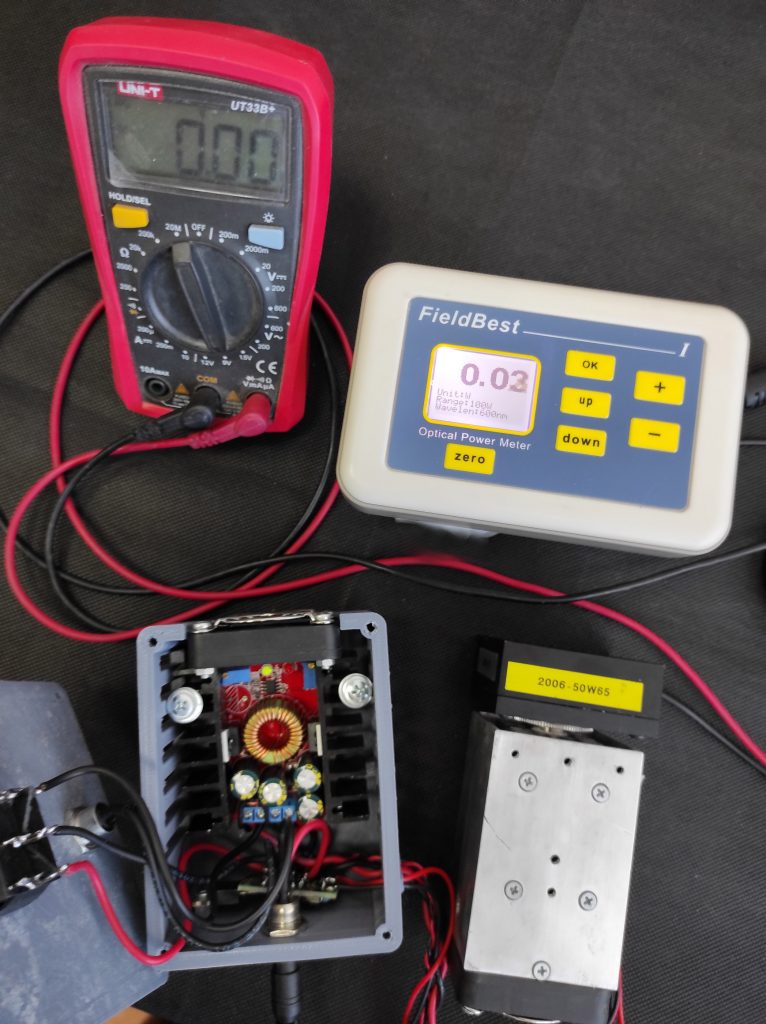

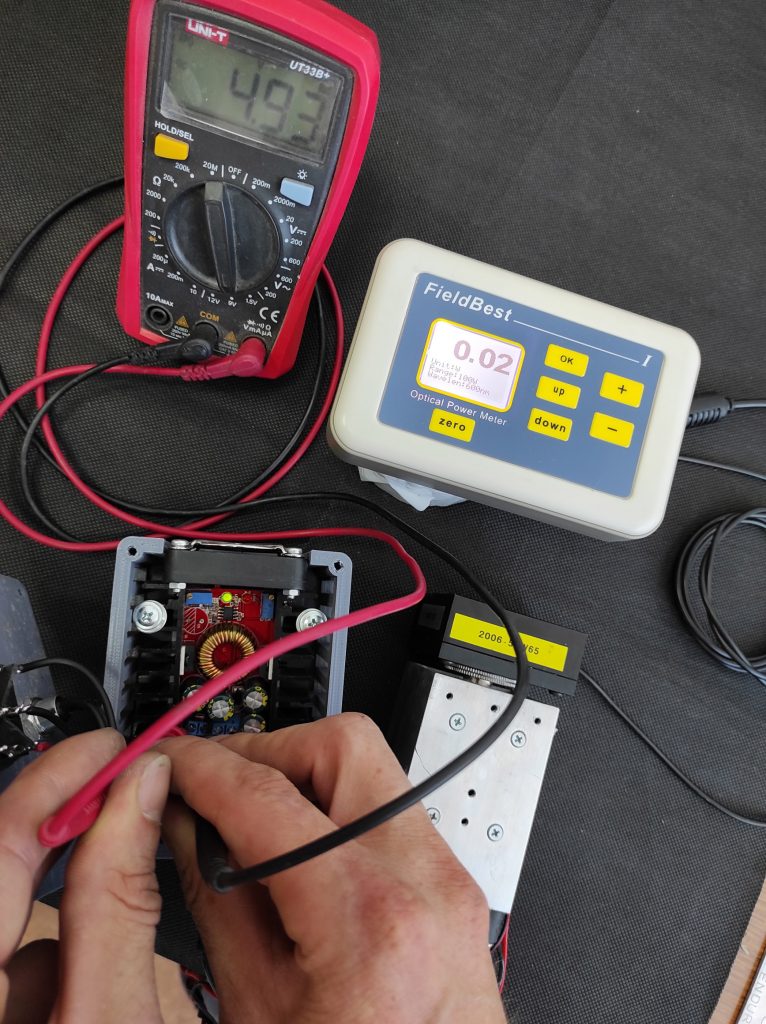

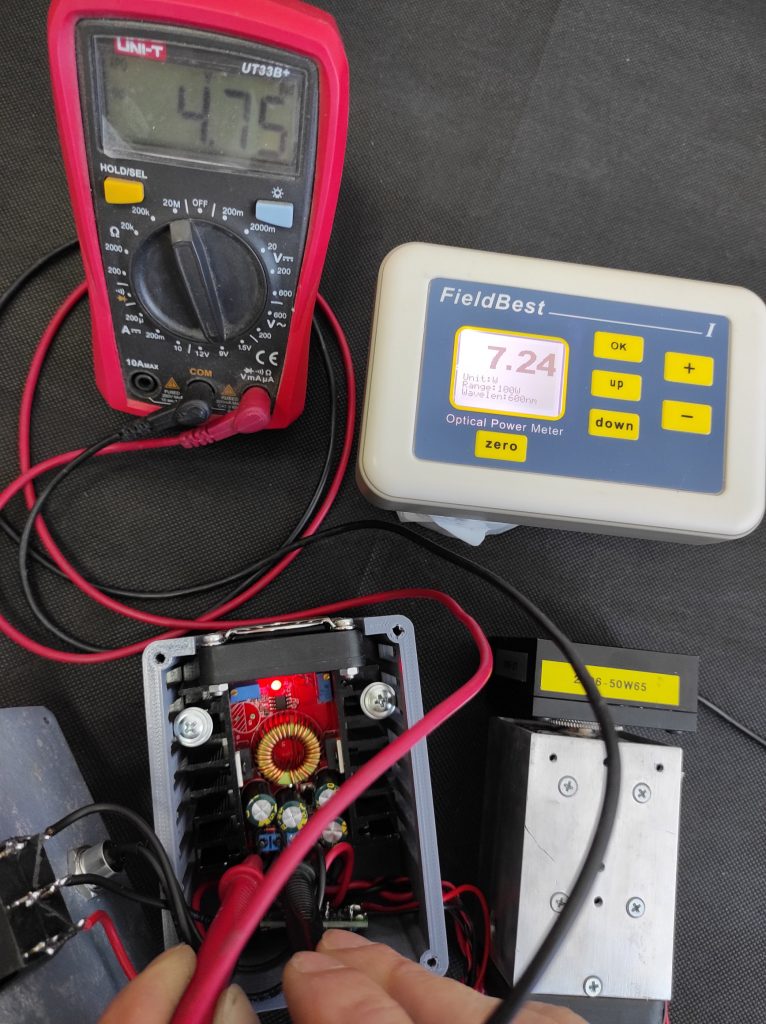

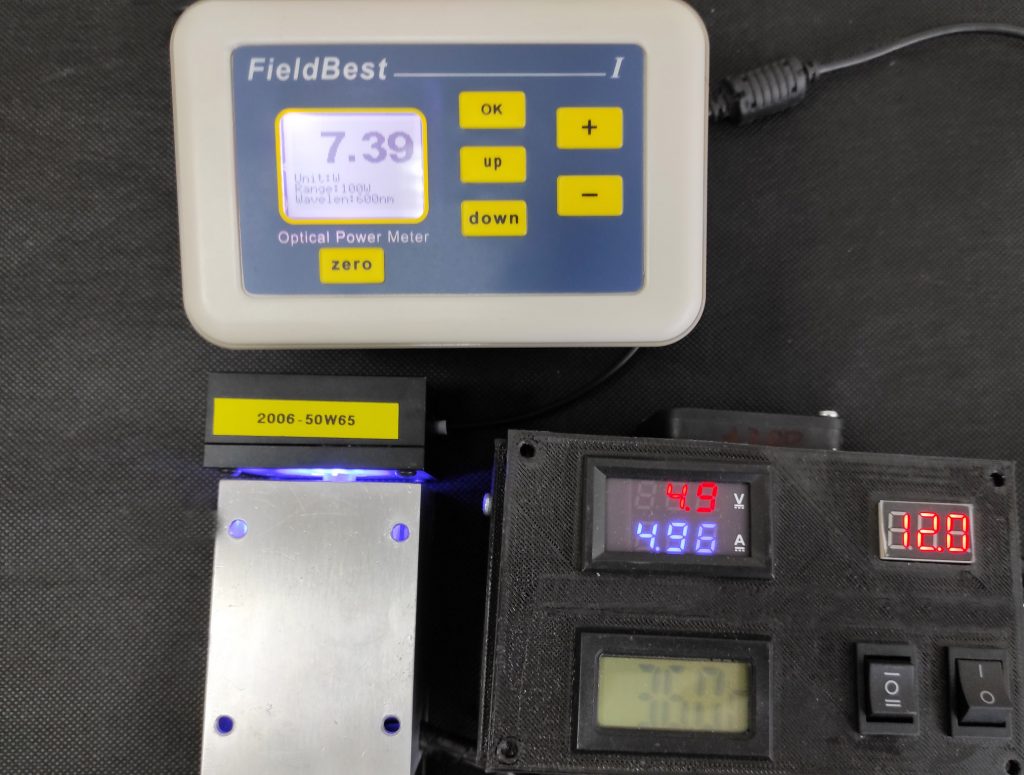

Testing all Endurance lasers using a calorimeter (power meter)

We run all lasers on such a stand to make sure the laser works properly in PWM and can operate full power without degrading the laser crystal.

PWM test on an Endurance 10 watt PLUS PRO laser (a perfect PWM)

Learn more about our testing stand.

Running the laser in impulse mode

The maximum laser frequency is for Endurance 10 watt models is 100 kHz!

Endurance made a measurement of the emitting area and we got results (Height X Width): 25+-10% x 275+-10% microns

Endurancer lasers specs (datasheet)

| Laser power | 10 watt PLUS/PRO/ Delux | 10 watt | 8.5 watt | 8 watt | 5.6 watt | 3.5 watt | 2.1 watt |

|---|---|---|---|---|---|---|---|

| Laser Type | Nichia diode | ||||||

| Diode model | NUBM47 | NUBM47 | NUBM44 | NUBM44 | NDB7A75 | NDBM08 | M140 |

| Max Laser Optical Power Output (in CW mode) | 7000-7500 mW | 7000-7500 mW | 6500-7000 mW | 6000-6500 mW | 4000-4500 mW | 2200-2700 mW | 1700-1800 mW |

| Max Laser Optical Power Output (in impulse mode) | 10000mW ± 5% | 10000mW ± 5% | 8500mW ± 5% | 8000mW ± 5% | 5600mW ± 5% | 3500mW ± 5% | 2100mW ± 5% |

| Focal Length | 2-10 cm (1-4”) (variable) for 3 element lens | 5-30 mm (1”) (variable) for G2 lens | ||||||

| Laser Wavelength | 445nm | ||||||

| Lens Type | 3 element long focal lens | G2 short focal lens | ||||||

| Operation Time | Tested 48-72 hours continuous | ||||||

| Voltage | 9-12V | 9-16V | |||||

| Current consumption | 5-8A | 5-8A | 5-6A | 4-5A | 3-4A | 2-3A | 1.5-1A |

| Cooling | TEC cooling with additional heatsink | Active air blowing with 4 fans | Active air blowing with 3 fans | Active air blowing with 1 fans | |||

| Mount | Ultra compatible and universal | ||||||

| Installation Process | Full guidance | ||||||

| Minimum Laser Pixel (spot) Size | 0.1 mm (100 uM) | ||||||

| Power adjustment | Endurance MO1 PCB (2 wires) | Additional wire TTL/PWM control (1-12V) | |||||

| Laser Dimensions (W x L x H) | 65 x 105 x 110 (115) mm (2.5 x 4.15 x 4.5)” | 60 x 95 x 60 mm (2.4 x 3.7 x 2.4)” | 55 x 95 x 105 mm (2.1 x 3.7 x 4.1)” | 50 x 95 x 50 mm (1.7 x 3.75 x 1.7)” | 50 x 95 x 50 mm (1.7 x 3.75 x 1.7)” | 40 x 95 x 40 mm (1.5 x 3.75 x 1.5)” | 40 x 95 x 40 mm (1.5 x 3.75 x 1.5)” |

| Laser Weight | 595 g (4/3″ lbs) | 216 g (1/2″ lbs) | 240 g (1/2″ lbs) | 240 g (1/2″ lbs) | 170 g (1/3″ lbs) | 150 g (1/3″ lbs) | 150 g (1/3″ lbs) |

| Laser Driver | External laser control box | Internal laser driver | |||||

| Lifetime | 10 000 hours+ | 10 000 hours | |||||

| Maintenance | Keep laser lens clean | ||||||

| Additional power | Required for fans and TEC cooling | Required for fans | Is not required | ||||

Wavelength shift depending on the laser diode temperature

Laser beam width changes depending on laser power consumption

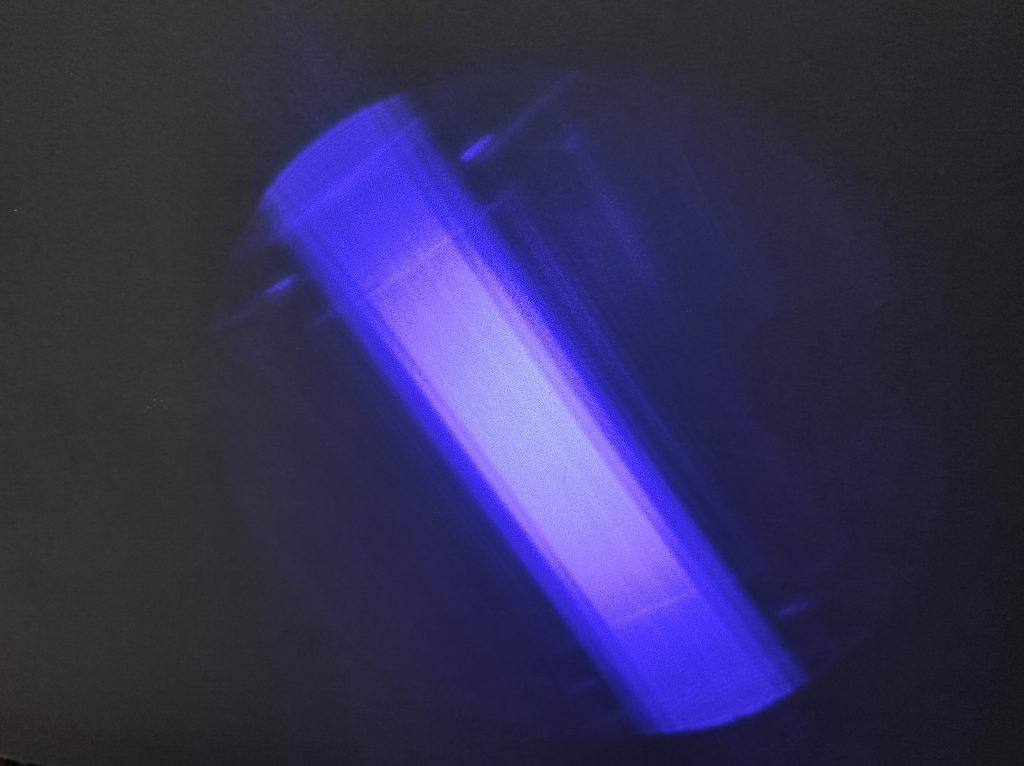

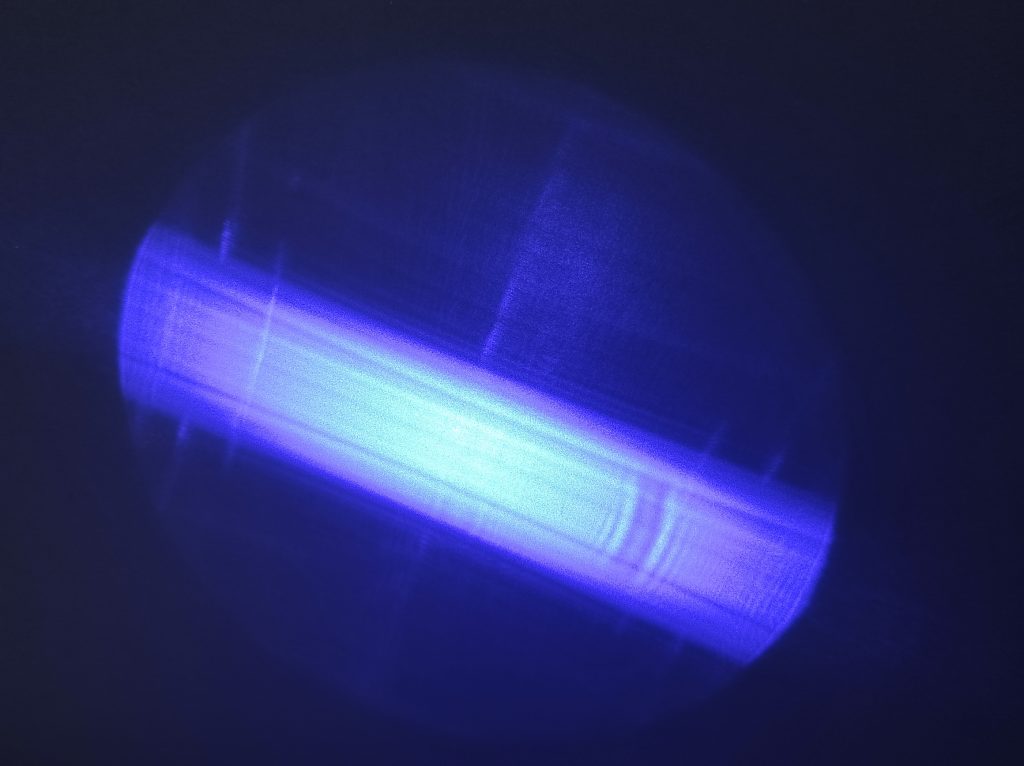

An excellent diode laser beam

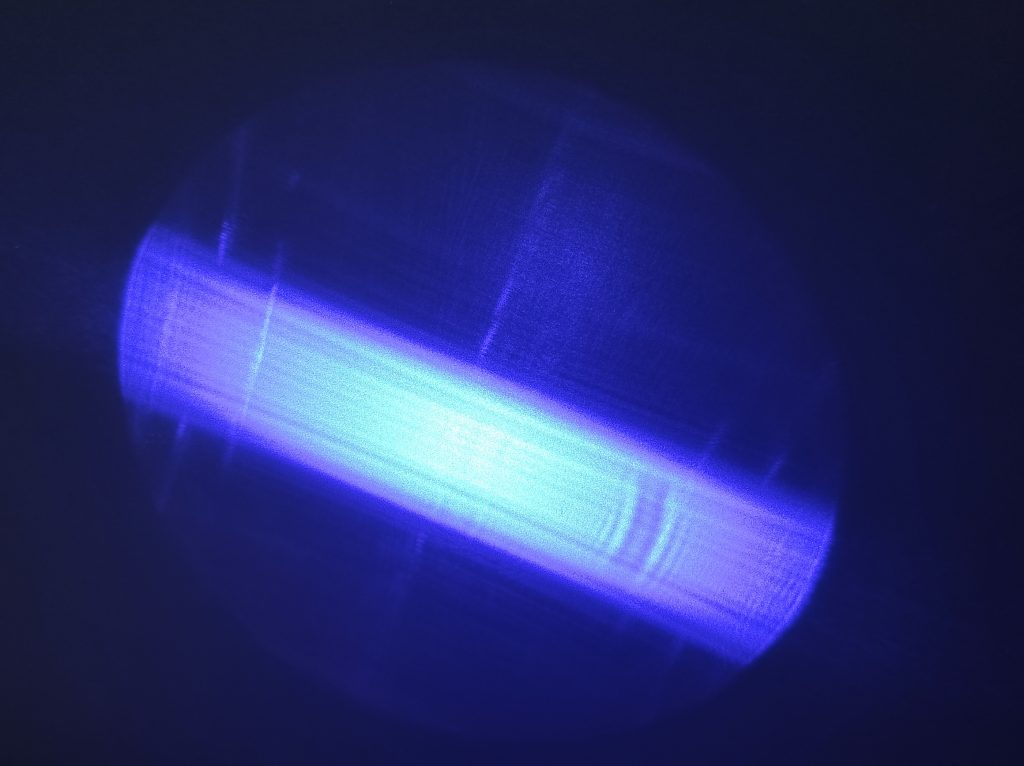

A damaged diode laser beam

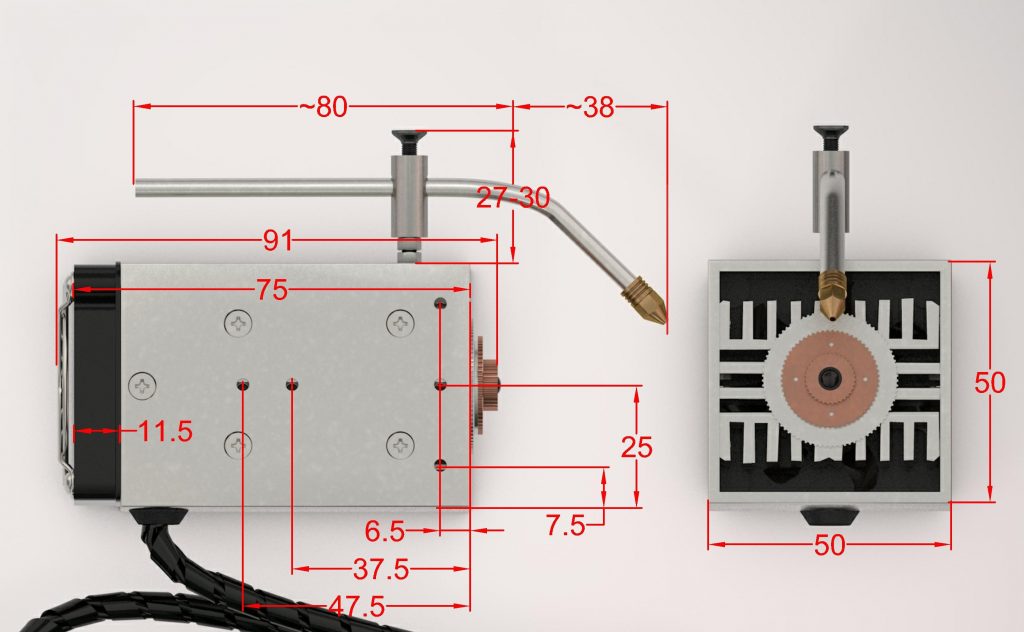

Endurance laser design

We have 2 design modifications for 2100 mW, 3500 mW, 5600 mW diode laser modules: smaller (11.5 x 4 x 4 cm, weight 160 gr.) and bigger (9.5 x 7.5 x 9 cm, weight 190 gr.)

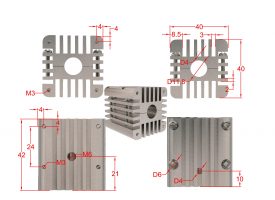

Endurance lasers drawing and sketches (incl. PRO versions)

Aluminum housing for 8 watt and 8.5 watt+ laser.

Aluminum plate for 20 watt laser (laser beam combiner mechanism).

10 watt and 10 watt+ laser aluminum housing.

Endurance custom build heatsink

Alternative aluminum housing ver 1.1

How to test the laser. An easy way

Endurance lasers are certified

Here is a declaration of conformity for all diode lasers that are produced by Endurance (Rus, PDF) | (Eng, PDF)

About laser diodes

A NUBM44 is a 445nm laser diode that emits 6 watts of optical power on average. At the moment it is the highest power laser diode in a 9mm TO-5 mount. A NUBM44 is specified with a typical center wavelength of 445nm (dark blue). This is a multi-mode laser diode, it has a pretty narrow waveguide, which allows it to have nearly the lowest etendue (far-field divergence for a given beam diameter) of any high-power semiconductor laser. The narrow emitter width enables to better collimate and focus it than other high-power laser diodes.

This is a big advantage of this unit.

The Key Advantage of Endurance Diode Lasers

The key advantage of all Endurance lasers is that you may simply replace a laser diode yourself.

Usually, our lasers work 8000-10000 hours and can work 48-72 hours non-stop but it happens that about 1-3#% of diodes burn faster, then we send a free replacement and it is very easy to replace a laser diode following our instructions.

This laser has a chemical formula of GaN. The laser operates at temperatures up to 60-65C without significant power or lifetime loss. But the colder the laser – the better. But if the temperature exceeds 70-80C the diode can dramatically lose its power before final degradation.

The temperature shift to colder parameters will decrease the laser wavelength.

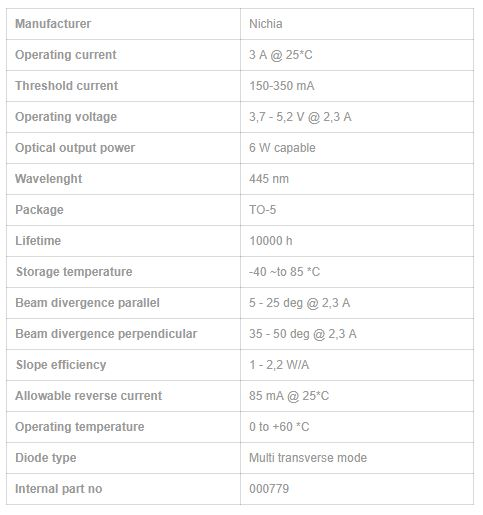

General datasheet about NUBM44

- Gallium Nitride (GaN) blue laser diode

- 6.0-watt blue laser, 445nm wavelength;

- easy to focus and collimate;

- a compact TO-5 (9mm) mount;

- a wide range of operating temperatures (0C to 65C);

- a longer lifetime at higher operating temperatures due to GaN.

The NUBM44 laser diode is temperature indifferent compared to other high-power semiconductor laser diodes. It is known to operate in a temperature range of 0C – 65C. The NUBM44 lifetime is 10 000 – 20 000 hours at 25C.

If the blue laser’s temperature goes up to 65C, the diode (laser) lifetime decreases very slightly, thanks to the recently developed Gallium Nitride laser technology. The Gallium Arsenide laser technology used for red and NIR laser diodes is unable to ensure the same.

Thus, this blue laser diode is a reliable choice for various environments and applications. Additionally, this GaN laser has a special TO-5 (9mm) mount, which helps reduce its thermal resistance. The 9mm TO-5 mount is hermetically sealed, which protects the semiconductor laser chip from dust and other contamination. In contrast, high-power red and NIR laser diodes typically require a C-mount package, which has an exposed facet, making them subject to issues with reliability if not operated in a clean-room environment.

The NUBM44 laser diode is relatively indifferent to higher operating temperatures, however, we do recommend using a suitable heatsink with a NUBM44 and other high-power laser diodes. Specifically, a low-thermal-resistance (ideally less than 1.5C/W) mount should be used due to a large amount of heat generated (approximately 12W) when this laser is operating full power.

A laser diode mount with low thermal resistance will reduce the amount of localized heating produced by the laser element and minimize the path to thermal ground. Such a TO mount will also reduce the amount of thermal drift, which affects both the power and wavelength. Thermal resistance can be minimized by pressing the TO header against a flat heat spreader surface machined from materials such as Aluminum, Copper or Brass; as well as by soldering it; applying a thin layer of thermal paste can also be helpful.

In order to collimate this laser diode well and collect as much light as possible, we recommend using a collimation lens with a high numerical aperture (e.g., NA greater than 0.50). This is because the far field divergence on the fast axis is typically 44 degrees. Without a fast (high-NA) lens, some of the power will be lost. Using a longer focal length lens will improve the blue laser diode’s ability to be collimated. To further reduce the slow axis divergence, it is possible to expand the beam on the slow axis using two cylindrical lenses, which Opt Lasers also provides on its website. However, in certain applications having a short working distance, it is sufficient to use only a single collimation lens.

There are numerous and varied applications for the NUBM44 diode due to its unique lasing wavelength of 445nm. Applications include engraving, phosphor pumping, fluorescence microscopy, imaging, optogenetics, RBG light sources, art and architecture, illumination and Thulium-doped fiber pumping, as well as many being currently developed. For example, by using this laser diode to pump phosphor, some of the lowest etendue white (broadband) light sources can be created.

Note that the NUBM44 laser diode is very similar to NUBM47. However, our testing suggests that NUBM44 has a lower threshold current and higher efficiency than NUBM47 as well as a similar lifetime and operating power of 6 watt. The ability of both laser diodes to be collimated and focused is also similar. For these, and other reasons which are proprietary, we believe the NUBM44 is currently the better option.

If a different violet, blue, green or red laser diode is preferred, other than 445nm, we also offer high-power lasers with other wavelengths, such as 405nm, 422nm, 465nm, 520nm, and 638nm. We also offer accessories for laser diodes. These include laser diode mounts, laser connectors, collimation and focusing lenses, including short focal G-2 lenses, cylindrical lens pairs, as well as electronics, such as TEC controllers and laser diode current drivers, Endurance MO1 PCB.

NUBM44 datasheet

Wavelength: 445(nm)

Output Power: 6000-7000 (mW)

Transerve model: Multi-model

Operation Model: CW

Ellipticity: >95%

Beam Quality(M2): <1.5

Power Stability <5% (rms,over 4hours)

Pointing Stability: <5% (mrad,after warm up)

Warm up Time: <1 (minutes)

Beam Divergence: <1.5 (mrad,full angle)

Beam Diameter: <1.5 (mm,at beam aperture after collimation lens)

Opeartion Tempearture: 0-65(°C)

Input Voltage: <5.5VDC

Input Current: >2A

Mount: TO-5 (9mm)

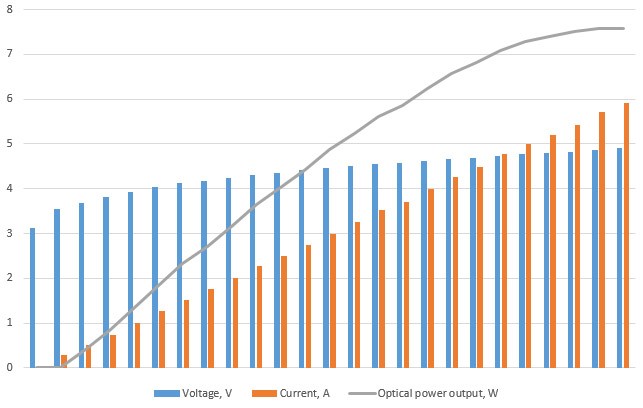

Independent NUBM44 / 47 NICHIA diode test 7W Blue Diode 450nm Long Term Testing 09/02/19

6 watt optical power can be reached @ 4.7A x 4.70 V = 22.09 W Input Power (by APS)

or @ 3.5 A x 4.53 V = 15.86 W Input Power (by DTR)

7 watt optical power can be reached @ 5.8A x 5.9V = 26.62W Input Power (by APS)

or @ 4.7 A x 4.77 V = 22.42 W Input Power (by DTR)

A new updated laser diodes datasheet (since December 2021)

| Voltage, V | Current, A | Optical power output, W | Laser diode temperature, C |

| 3,13 | 0,01 | 0 | 20 |

| 3,54 | 0,29 | 0,01 | 20 |

| 3,69 | 0,52 | 0,42 | 20 |

| 3,81 | 0,73 | 0,83 | 20 |

| 3,93 | 1 | 1,32 | 20 |

| 4,03 | 1,26 | 1,85 | 20 |

| 4,12 | 1,51 | 2,34 | 20 |

| 4,17 | 1,76 | 2,7 | 20 |

| 4,25 | 2 | 3,16 | 20 |

| 4,31 | 2,27 | 3,65 | 20 |

| 4,36 | 2,5 | 4,03 | 20 |

| 4,41 | 2,75 | 4,42 | 20 |

| 4,46 | 3 | 4,88 | 20 |

| 4,51 | 3,25 | 5,24 | 20 |

| 4,55 | 3,52 | 5,62 | 20 |

| 4,58 | 3,71 | 5,87 | 20 |

| 4,62 | 4 | 6,23 | 20 |

| 4,66 | 4,27 | 6,58 | 20 |

| 4,69 | 4,49 | 6,81 | 20 |

| 4,73 | 4,77 | 7,09 | 20 |

| 4,77 | 5 | 7,28 | 20 |

| 4,8 | 5,21 | 7,41 | 20 |

| 4,83 | 5,43 | 7,51 | 21 |

| 4,87 | 5,71 | 7,57 | 21 |

| 4,9 | 5,92 | 7,57 | 22 |

A BRAND NEW Z80 laser diode is available. The most powerful 445 nm laser diode on the market now.

We will start using them on our 10 watt PLUS PRO LASERS!

Z 80 laser diode (Download a brand new 445 nm laser diode datasheet (PDF))

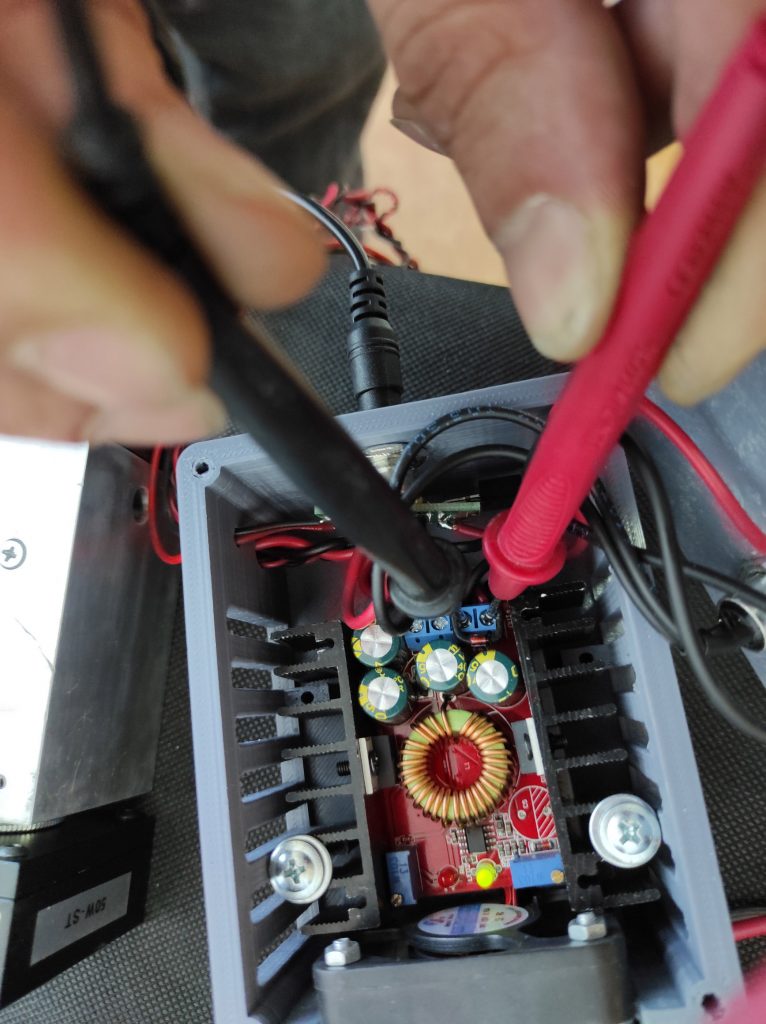

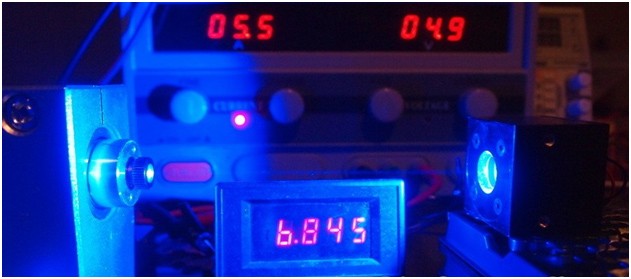

Testing NUBM44 / 47 NICHIA Laser Diodes. Measuring Voltage, Current, Optical Power.

We test each diode carefully. If the diode is underpowered then we do not put it into our production. Quality is an Endurance top priority.

Endurance lasers power consumption

Measuring of voltage, current, and wattage

High-quality standard

Multi-level testing system.

Industrial components.

Ultra reliable

The guaranteed duration of the continuous operation ~48-72 hours.

True continuous power output

Our products have the rated power output as advertised – unlike Chinese analogues.

TTL mode

Can be turned on and off with 3.5-24V.

Variable power output.

Plug and play

Universal and compatible mount.

Compatible with most 3D printers and CNC machines.

Friendly return policy

Do not like the laser?

Simply return within 30 days and get a full refund.

Real-time advice

We assist and give advice by Phone / Email / Facebook messenger / Telegram / Whatsapp / Viber.

Professional support

We help to install and tune the laser. We offer qualified after-sales support.

Everything you need

We ship everything you need in one parcel to get started.

Immediate delivery

We ship all units within 4-24 hours. DHL express delivery allows you to get the package in 3-5 days.

Lifetime warranty

All our lasers are tested and could work up to 10000 hours.

Upgrade option

Do you have an old model? Upgrade your unit with more powerful one.