Polyurethane Protection Film for Different Surfaces

Our Endurance Lasers laboratory came to be in possession of some polyurethane protection film, 180 mu thick ( http://surl.li/aplyr ), and we decided to browse the Internet in order to see what people used it for.

What is polyurethane?

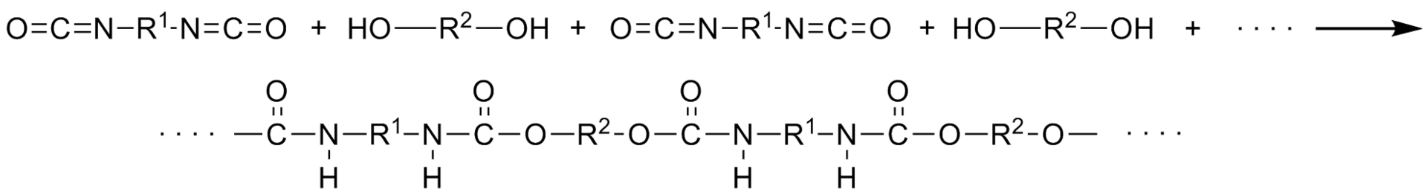

Despite the popularity of this material, few people know what this material actually is. Dealing with it so often, we have never focused on it. Polyurethane is a modern all-purpose material used in various spheres of economics. Being absolutely safe, makes our life more comfortable. Polyol and isocyanate are their basic components. The technical features of the raw material depending on its molecular structure.

For industrial purposes, they started to produce polyurethanes in 1937. Six years later Germany launched the production of composite urethane foams, which had high monetary value. That is why the material was not commercially successful in the market. But in 1957 an analog of the modern material notable for its high-performance and low price was produced.

Why is polyurethane so vital?

The secret of this material lies in its unique properties, which vary in a wide range. It can be both very soft and amazingly hard.

Many consumers erroneously consider urethanes to be in one group with plastics or rubber. But actually, it is neither one thing nor the other. In fact, it is a synthetic elastomer based on heterochain-type organ element polymers. Various modifiers and additives in their composition alter the characteristics of the end product. Polyurethane is the best alternative to rubber. Work products made of this material demonstrate high performance in an aggressive environment and high temperatures.

On the results of our Internet search, it appears that such like films are used for protection of painted, polished or glass surfaces from chipping, scraping, cracking, etc.

The major market for polyurethane films is car services. The film is pasted over headlights, body parts and windshields to protect them from possible mechanical damage.

Besides, the film is used to protect the surfaces of smartphones.

So, our idea was to cut out corresponding film pieces to protect our smartphones from mechanical damages.

To do cutting we’ll use a 10 watt PLUS PRO LASER

In the beginning, we have to measure the size of the phone screen.

You can find all the size values on the Internet, but we used a trammel to make it easy.

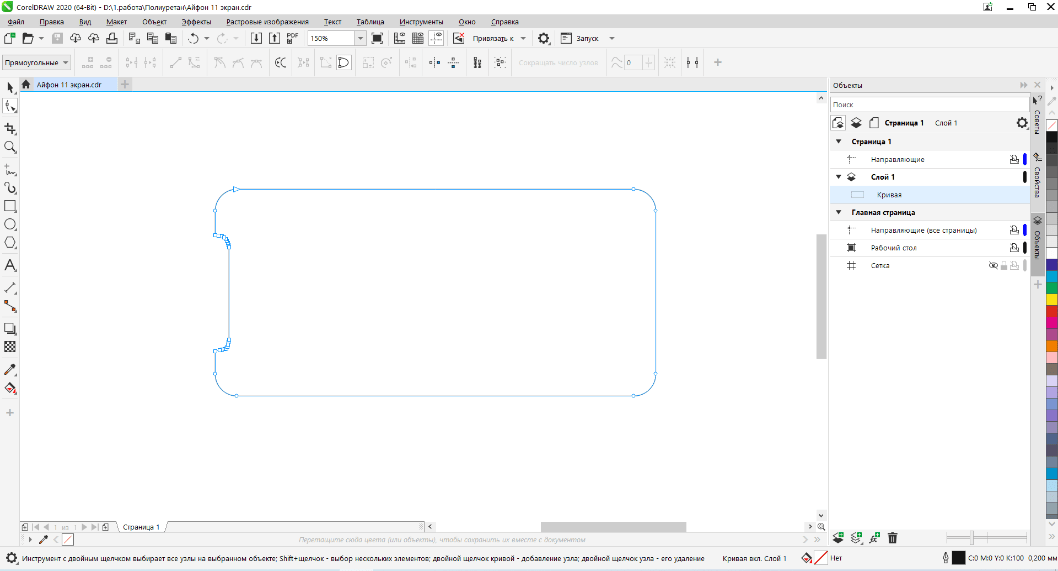

In the Coral Draw program for the creation of vector images (it is possible to use any other), we create an outline of our screen.

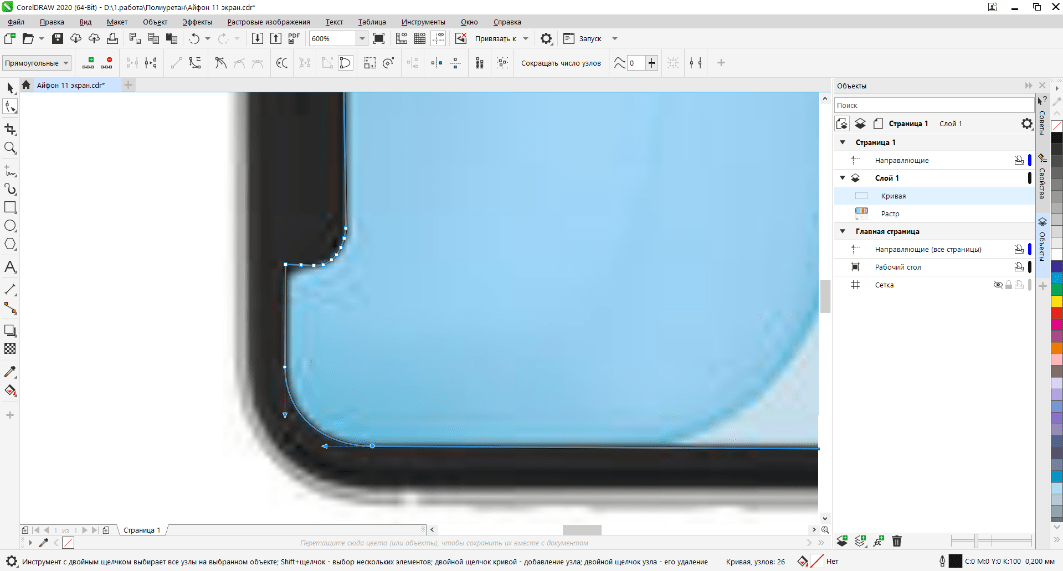

To make the outline as precise as possible regarding the angles and openings it is possible to use a phone photo from the Internet putting it under the vector outline.

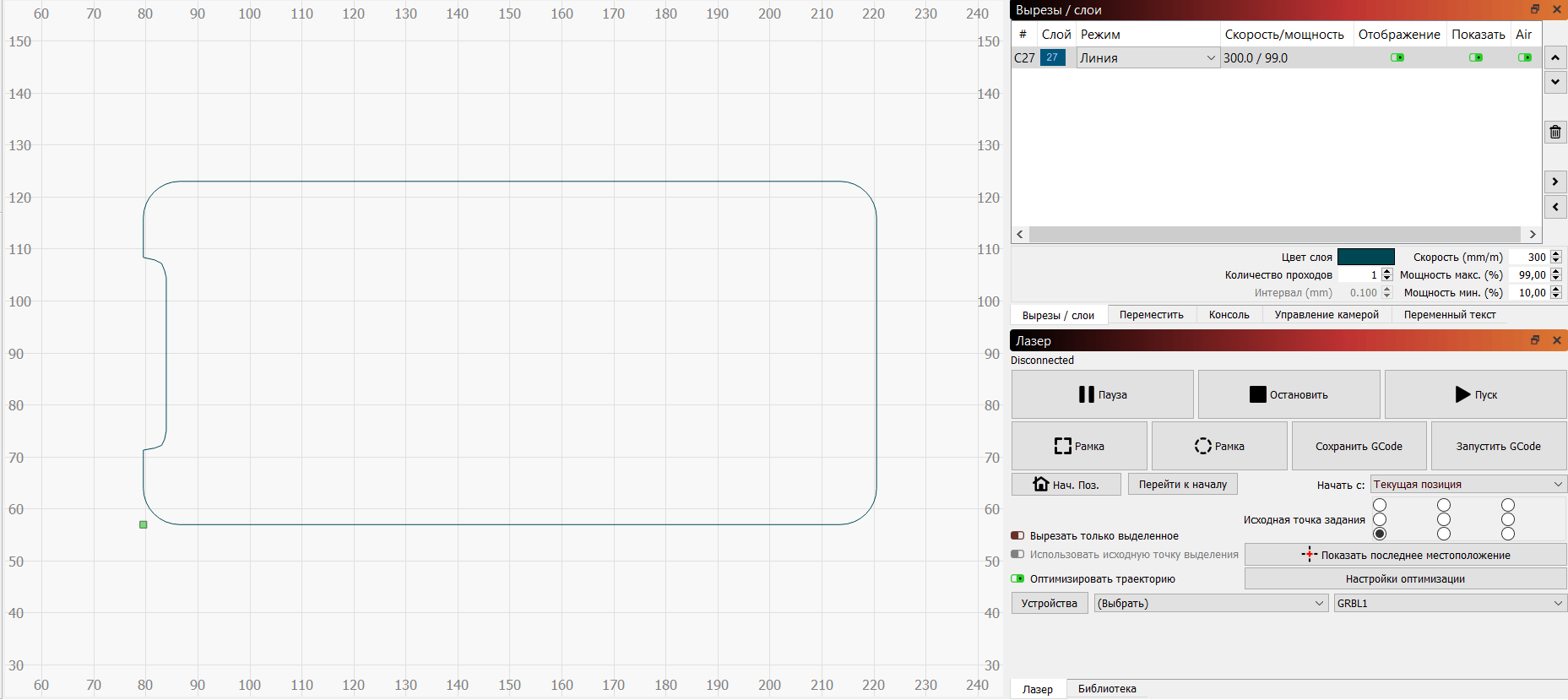

Then we export the image as an SVG file to the LightBurn software where we set up the cutting parameters.

Before experimenting with any material it’s worthwhile doing a test. The optimal speed for polyurethane, 180 mu thick, is 300 mm/min. and 100% power.

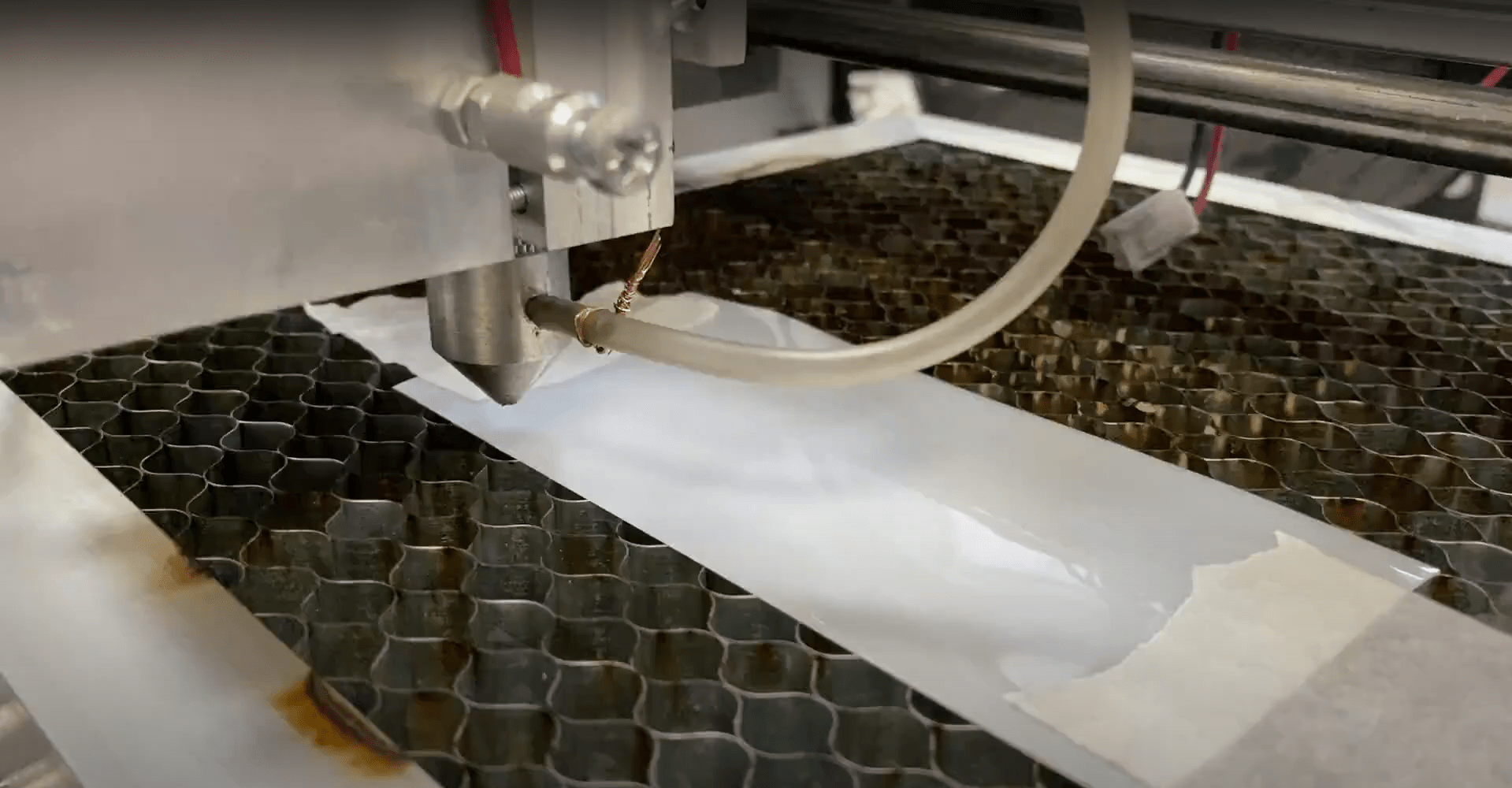

After we are done with the preparatory work we cut out a film piece of the suitable sizes with slight allowances for fastening the film piece to the worktable.

Using masking tape, we attach the film piece to the honeycomb worktable, turn on an air assist and an exhaust fan, put on special green safety goggles, and set to work.

Toxic gases are generated in the process of polyurethane laser cutting, so the use of any exhaust system is absolutely necessary. You can purchase an exhaust system box on our site. Having completed the cutting process, we carefully remove the finished item from the working field of the machine and check if it fits in the phone screen size. It perfectly does.

But the most difficult part of work – pasting – is still ahead of us.

We’ll need soap solutions, paper towels, alcohol, and a bank or discount card.

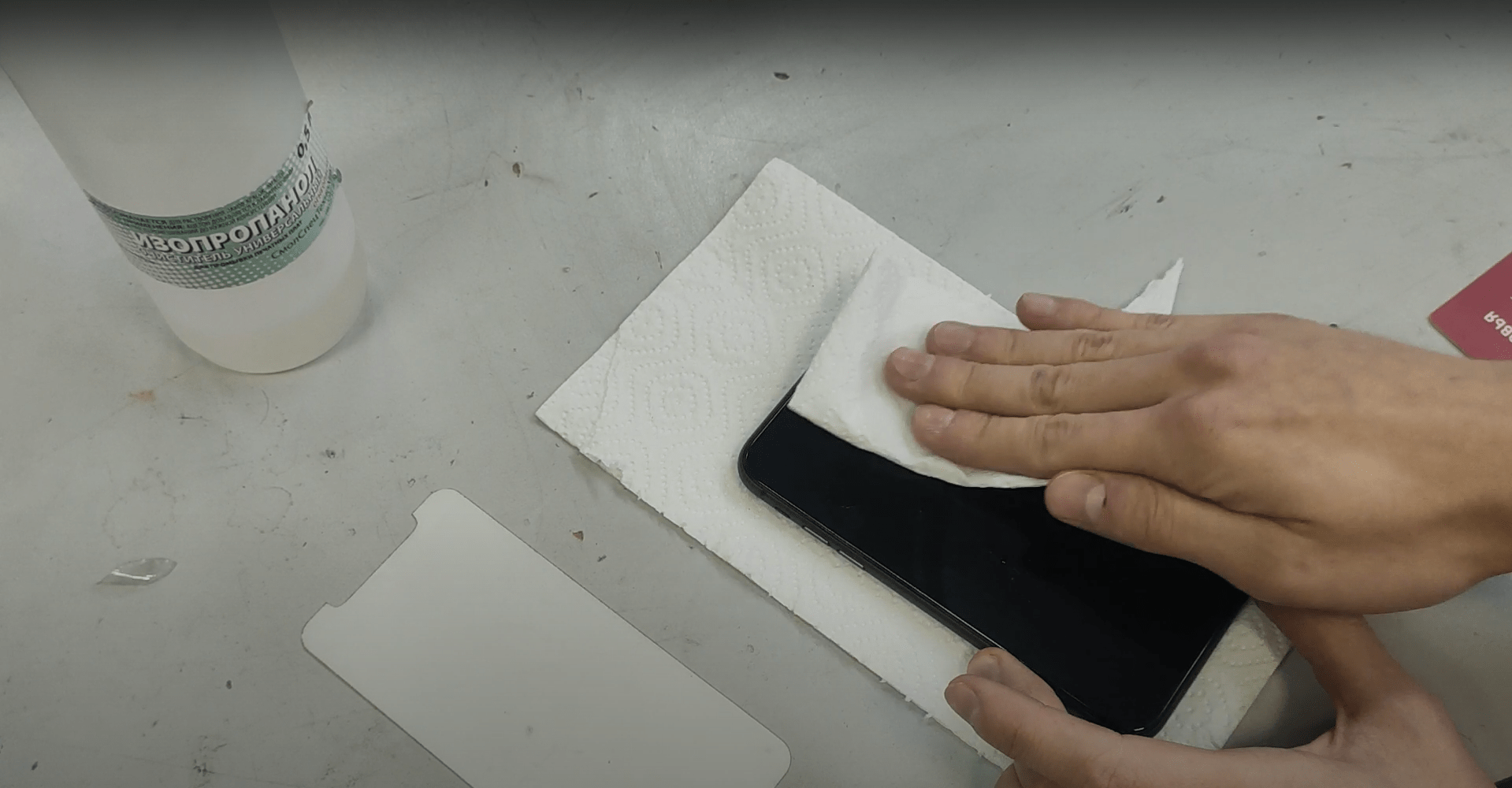

First of all, we wipe the phone screen with alcohol to degrease the glass surface and prepare it for pasting.

Then we treat the screen with soap solution. We sprayed it, but you can also rub your hands with soap and then palm rub the screen.

Then we peel off the matte layer from our film piece to make it ready for pasting.

Now we need to attach the film to the screen in such a way that all the openings and edges match. Due to the soap, the film glides easily on the surface we have enough time to center the film perfectly.

After this, we blot the soap solution excess using a paper towel wrapped around a bank (discount) card.

Finished!

The film is absolutely transparent. It does not distort the display colors and is nice to touch.

It is possible to use this film not only for phone screens but also for any even surfaces.

If you have any more questions – you are welcome to ask in our LiveChat!

Endurance lasers: all about cutting and engraving abilities of diode, DPSS, fiber, Co2 lasers.