10W+ vs. 10W

I recently had the chance to take a look at the 10W+ Laser form Endurance and compare it to my 10W model. While the laser itself is only marginally more powerful, the entire package gives a much better impression and has some definite advantages.

Overview

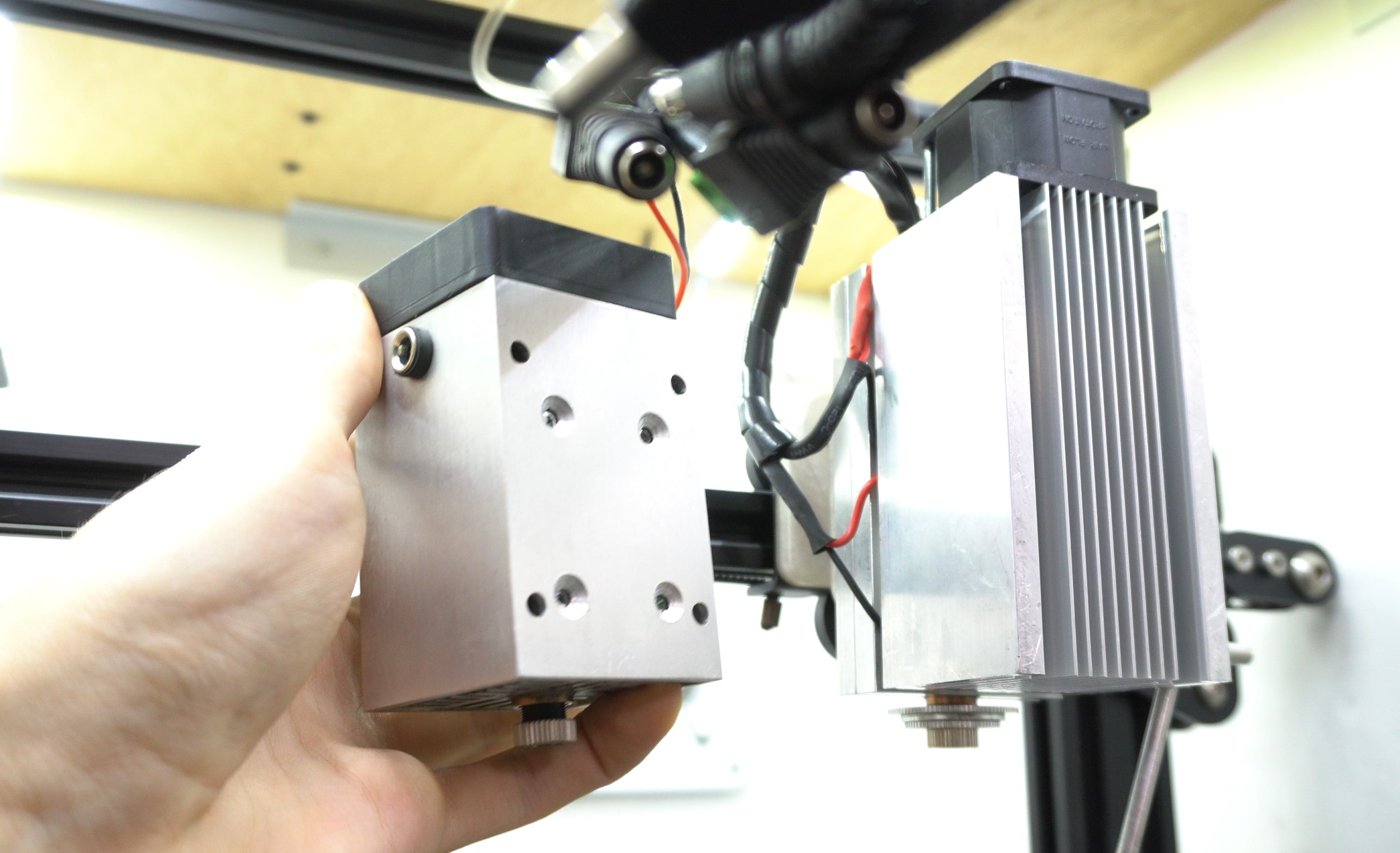

When unboxing the laser, the first thing that is apparent with the 10W+ is the heft of everything. Both the laser and the Laserbox are made out of metal, giving an excellent impression. For the Laserbox, this is an especially welcome surprise, as the regular 10W model comes with a 3d printed case, that feels more like a prototype. On the Laserbox, we have an on/off switch, a key to turn it on and off, an input voltage readout, a temperature readout for the laser, a mode selector switch, and a voltage and amperage meter for the laser output. This should give you all the tools to monitor and control the laser. On the 10W model, however, there is only a single switch to turn on the laser and change from full power to PWM. Speaking of PWM, on the 10W+, you can control the laser power either with a PWM signal or with an analog 0-10V signal that is internally translated to PWM. This gives you some more flexibility compared to the 10W laser that only accepts PWM.

Powering the beast

The only thing in the box of the 10W+, apart from the laser, are some stickers and three 12V 8A power supplies. Yes, you read correctly, the 10W+ Laser requires three separate PSU. One of them is for the laser itself, while the other two are for the two Peltier elements. This does minder the professional appearance of the Laserbox quite a bit, as it would have been much more convenient to have just a single power supply attached to the Laserbox, supplying everything with power. The 10W model, in comparison, only needs one PSU. If you are retrofitting a 3d printer, you can replace at least some of the power supplies with the one of the 3d printer. This works because you are not using the hotend and heated bed while lasering, leaving you with enough power for the laser. Depending on how your printer controller board is set up, you might run into problems with the PWM if you connect the Laserbox of the 10W+ to the same power supply as the printer. On the 10W model, that is not an issue.

Performance

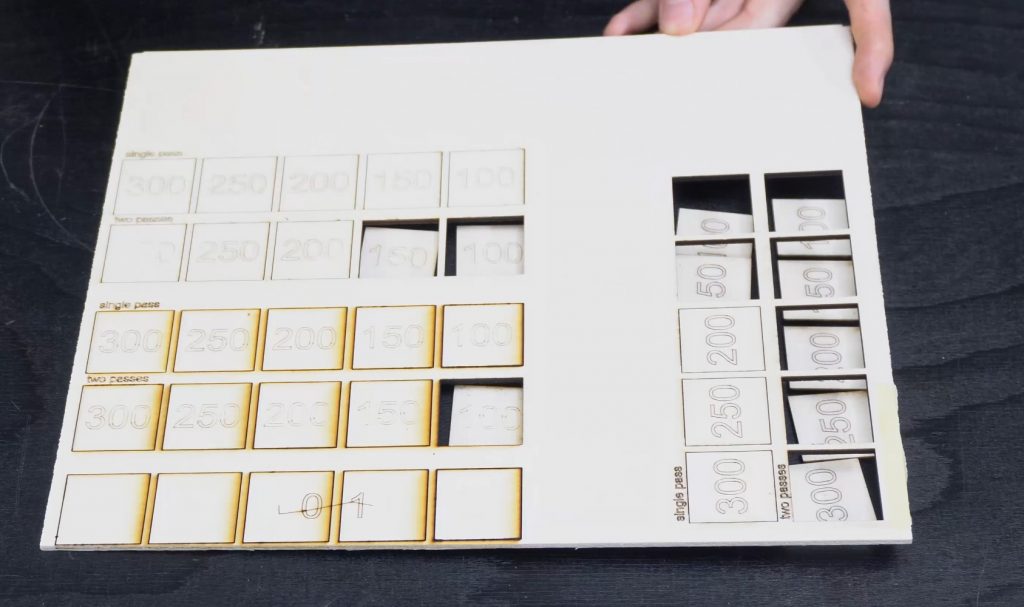

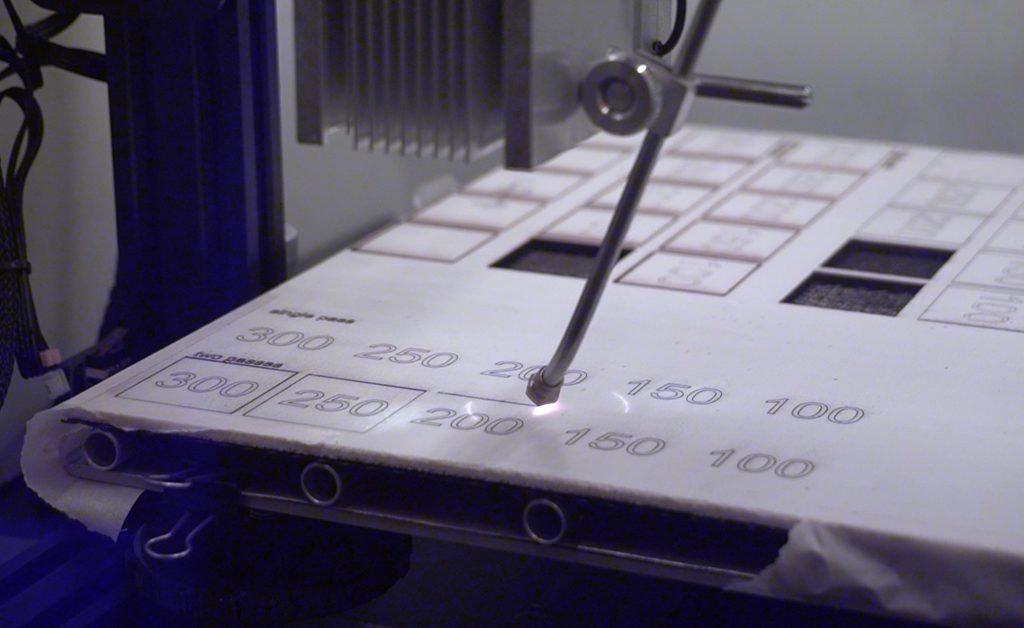

Once everything is set up, let us take a look at the performance. As the 10W+ laser is using the same diode as the 10W laser, just run at a slightly higher voltage, the cutting performance is similar. However, the increased power and also the air assist does give it an edge, making cutting just a bit faster. Where cutting 3mm plywood in 2 passes is possible at 200mm/min on the 10W, you can crank it up to 300mm/min on the 10W+. In 3mm red acrylic, a reduction from 6 to 4 passes was possible at 200mm/min.

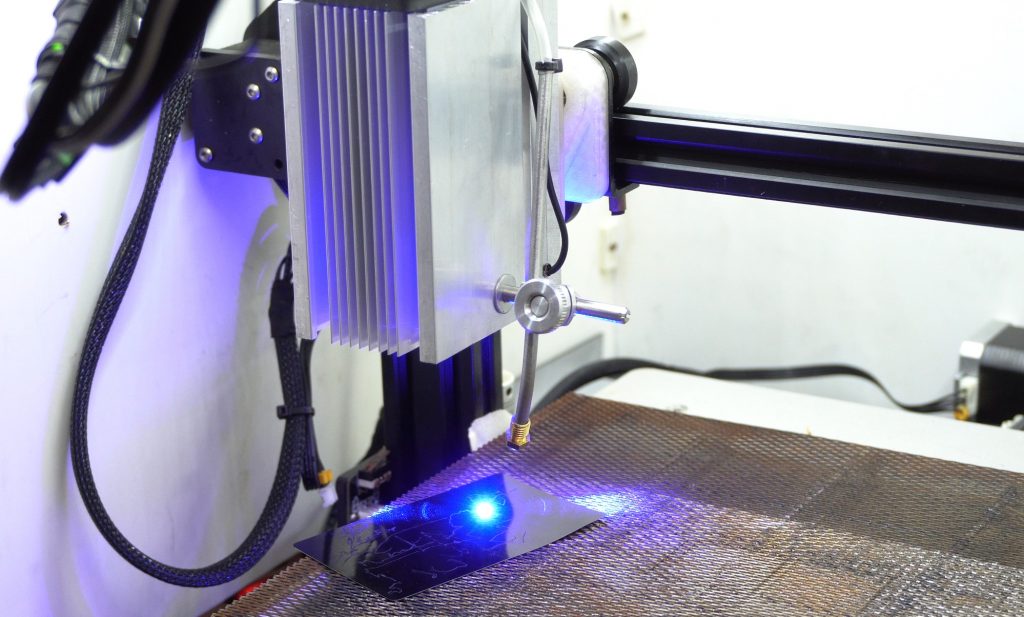

Air-Assist

However, the most significant difference between the 10W+ and other diode lasers is the air assist. Especially in wood, the cuts turn out much cleaner and don’t have discolorations around them. The takeaway from this is that no matter what laser you have if you are cutting wood, get an air assist. The only time when an air assist will hurt you instead of helping is when cutting acrylic. This is because when the plastic is molten before it is vaporized, the air assist can blow it around, creating strings and messy edges.

Conclusion

Overall the 10W+ has some advantages compared to the 10W Laser. If you are planning to cut a lot of wood, you will have to get an air-assist anyways, so the increased price of the 10W+ is not so much more. You also just get a much more complete system with the 10W+ thanks to the new Laserbox. If all you care about is raw laser power per dollar, then the 10W model will be better for you, as the power increase is minor.