PCB board can be easily made at home with a laser and 3D printer. We will provide a step-by-step walkthrough guide for you to learn how to make a PCB board at home. This is perfected for DIY makers. With practice and your Endurance laser, you can start easily making your very own PCB.

Before you begin, safety is paramount. Protective goggles should always be worn when working with your laser. Any of the protective goggles provided with your Endurance laser will protect your eyes from long-term damage and accidents.

An enclosure is recommended to avoid any harmful chemicals and fumes that can reach the air.

Diode lasers have many capabilities and one of them includes being able to create the commonly used Printed Circuit Boards (PCBs). A PCB is a printed circuit board layout that is the foundation used to connect electronic components. A PCB-board is also known as Printed Circuit Board Assembly (PCBA).

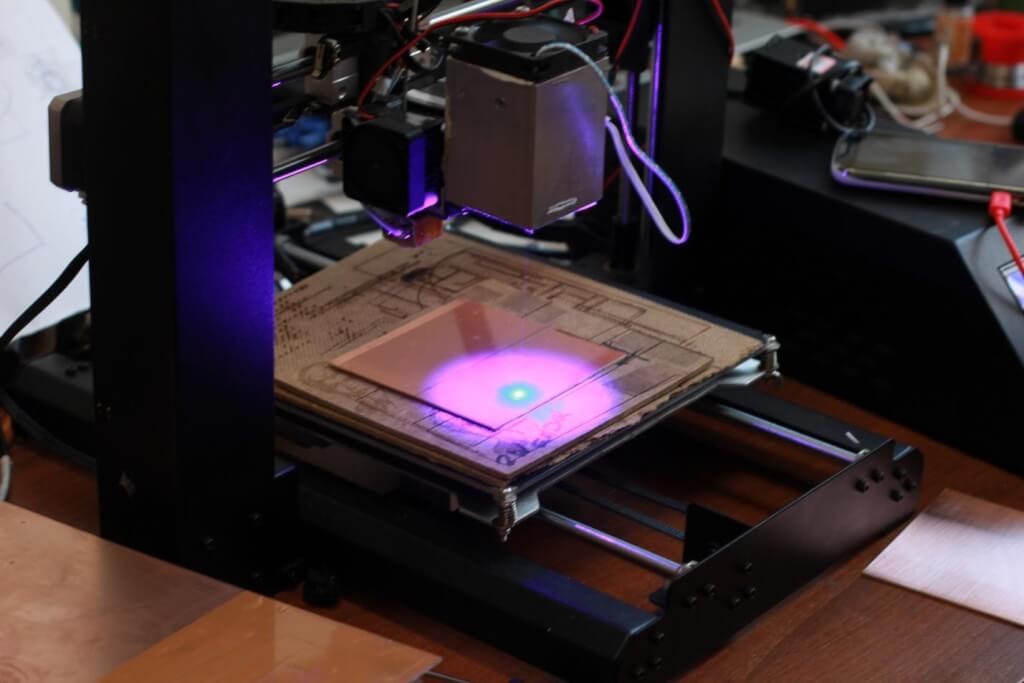

Creating a PCB board is one of the many useful and innovative ideas you can use your Endurance laser to do. PCB boards are often made with copper.

Laser etching a printed circuit board is easily possible with the right parameters set with an Endurance laser machine right at home. With an Endurance laser and following our guide, you can etch PCBs with ease.

This detailed guide will show you how to make a PCB board at home using your DIY laser engraver. Other methods are not ideal for etching PCB boards.

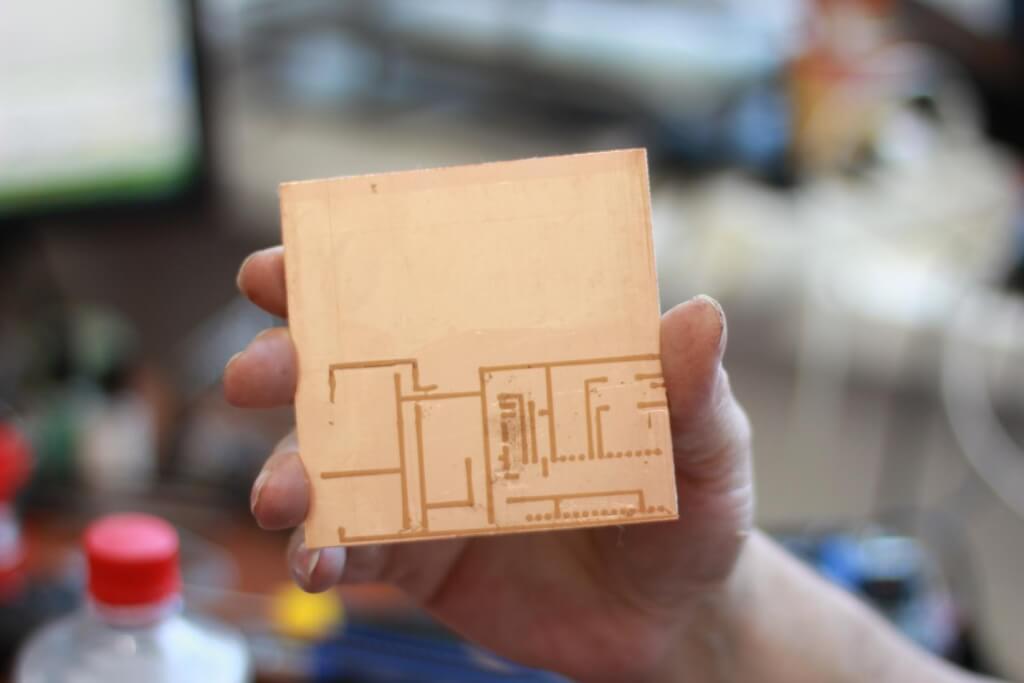

With a consistent stable power and laser focus, Endurance laser can give you a precise and accurate etch. The final result is smooth, accurate, and very detailed.

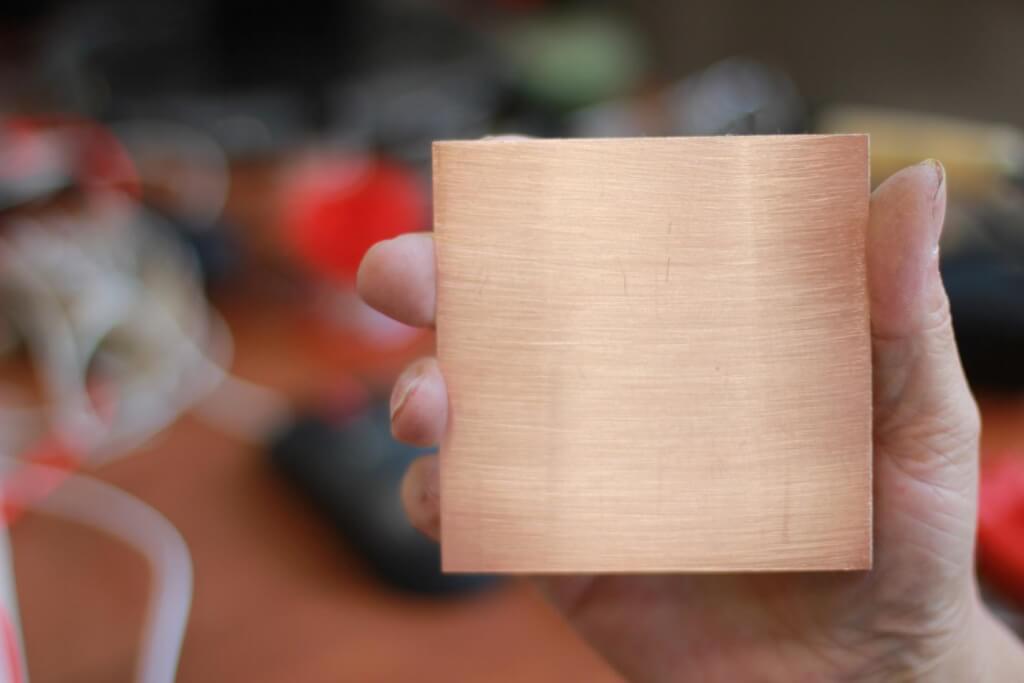

Before you begin, make sure your blank board is clean and free of glue, stains, or any possible visible remnants on the board.

Next, focus your laser.

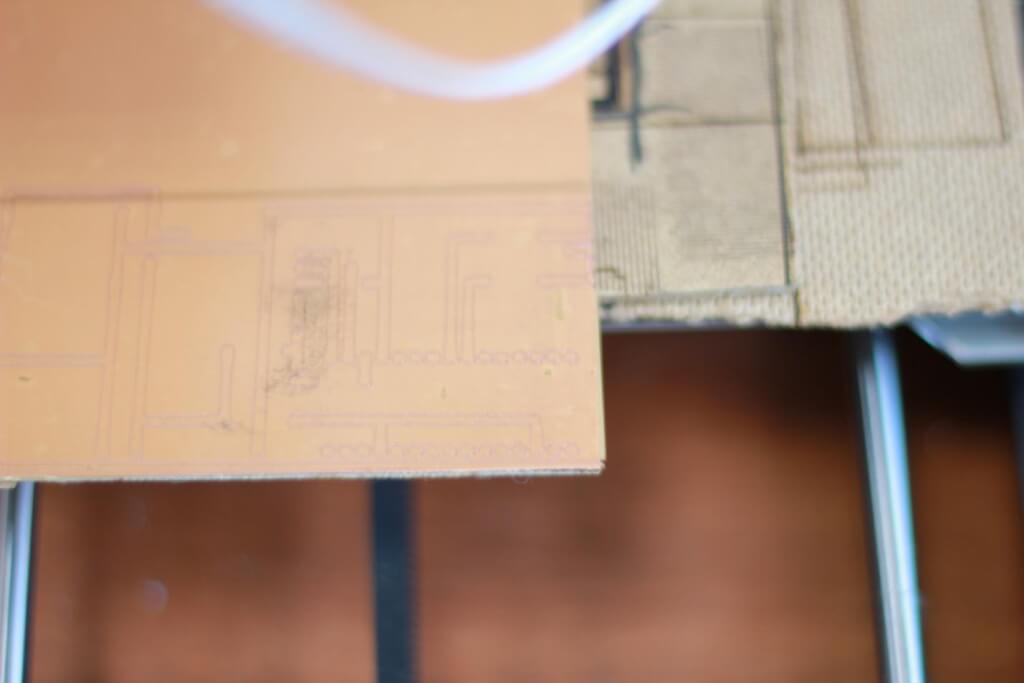

A well-focused laser will help you achieve better results in anything you do with your laser. For a PCB board, the accuracy from what is designed relies on a properly focused laser. The exact and accurate etch also relies on consistent speed and power settings. Laser etching does not require high power all the time, the right parameters and power will allow for good and clear results.

How to make your own PCB at home with Endurance lasers – a detailed guide!

3D printers have opened endless possibilities for home production and rapid prototyping. Now you can easily create practically any model in a 3D-program and 3D print it. But until now, only a few people have thought about the possibility of 3D print electronics for this or that solution (model).

Up to this day to make a circuit board for a prototype one had to pore over it with a soldering iron or to order a short production run. However, many of us can make it using a conventional iron and a laser printer.

Though, this process is not very pleasing either aesthetically or technologically. In this article, we would like to describe another method. Not only any 3D printer but also any DIY Engraver will be fit for it or a Makeblock XY-plotter.

Unsure if you wanted to keep the video available upon request or keep as is.

Assembling a DIY engraving machine (a universal laser engraver)

or a constructor of a makeblock plotter xy type

By the way, you can install a diode laser almost on any 3D printer, setting it as an addition or in place of the extruder. Diode lasers are small in size and compact. Their relatively small power output compared with that of CO2 lasers is not a drawback in this case.

So, what does the process of circuit board manufacturing at home or in the office look like?

For this, we need a copperized glass fiber plate, any dark vinyl film (any dark film that a laser can burn through will fit), iron chloride (sold openly in stores of chemical reagents) and, of course, a diode laser installed on a 3D printer. Its power output is not so very important, but we recommend to use a diode laser of more than 2W (2000 mW).

To install a laser on any 3D printer is very easy …

How to install it on Ultimaker Lasers and engravers. Endurance.

Laser engraving for yourself and for your business.

Video available upon request. Just email to [email protected] or text: 12393020053 [whatsapp, viber, telegram, wechat]

So, let’s begin:

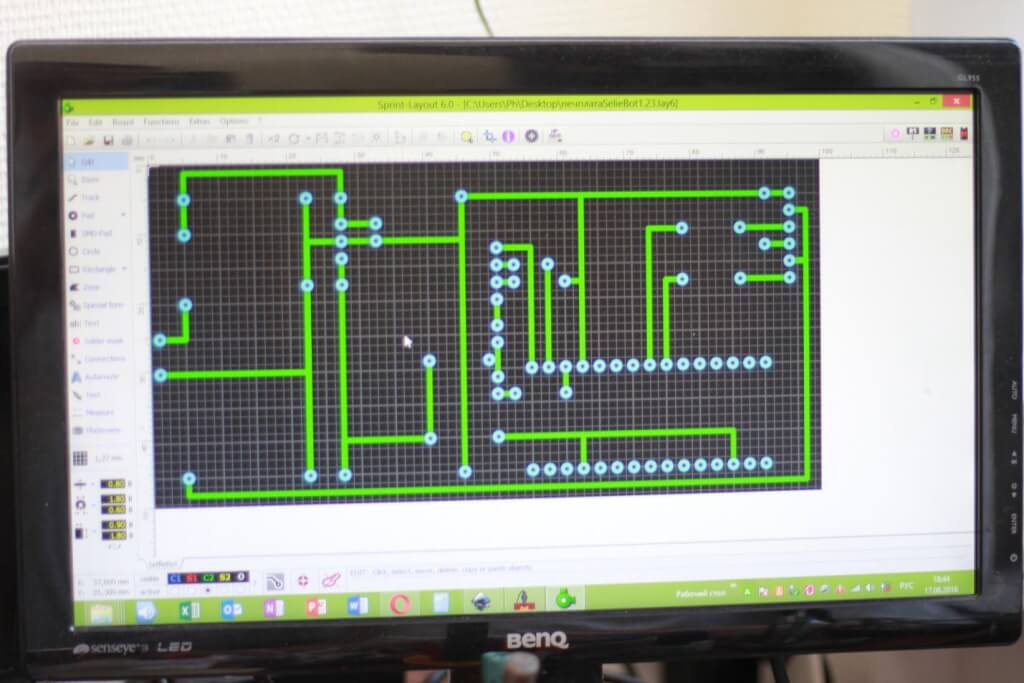

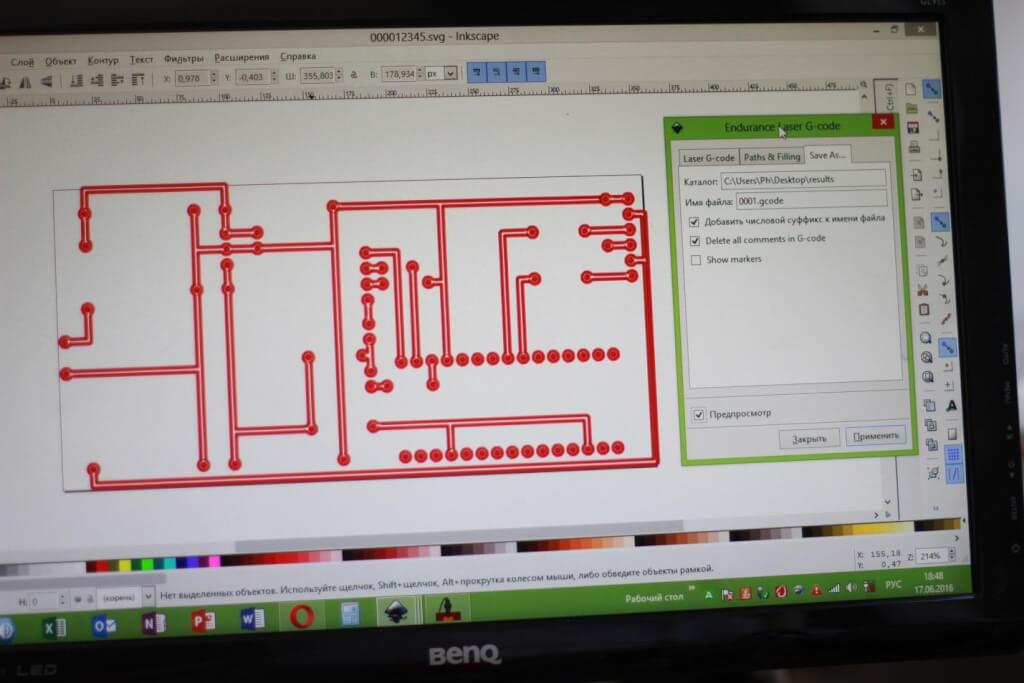

Create a circuit board model using any program of an InkScape type (inversion picture. Later, we’ll explain why inversion).

2. Convert it into the G-code.

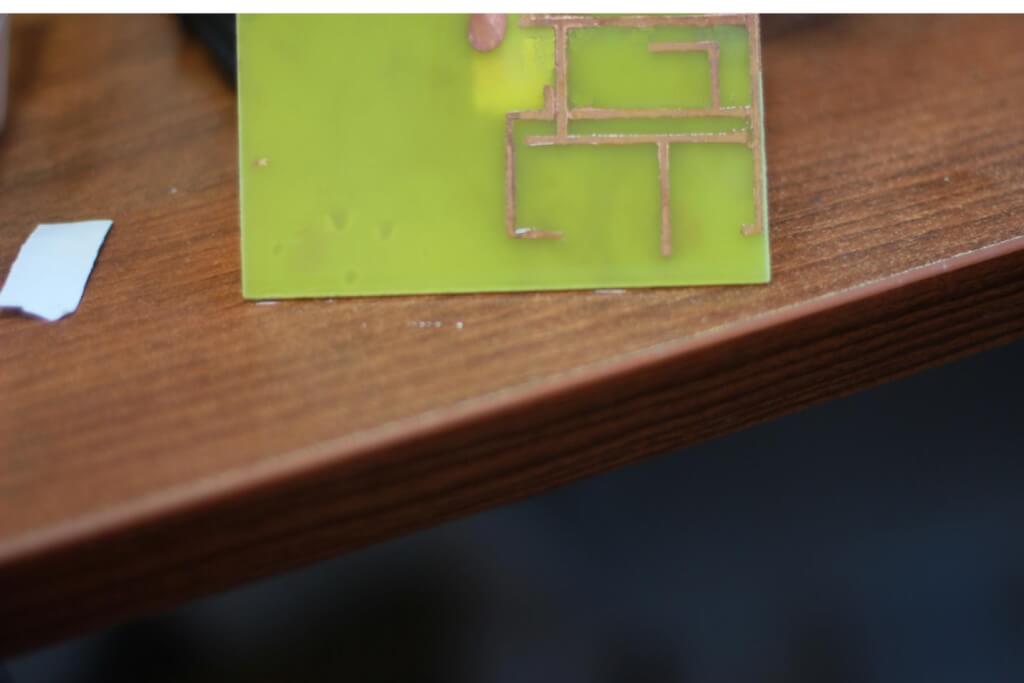

3. Stick the vinyl film onto the copperized plate of glass fiber.

4. Place the vinyl coated glass fiber plate onto the work table of the 3D printer, and turn on the 3D printer in the laser cutting / engraving mode.

5. The laser will burn on the vinyl film an inversion image of the pattern to be resulted.

6. Dissolve the iron chloride powder in water (do not worry, no chemical reaction will follow)

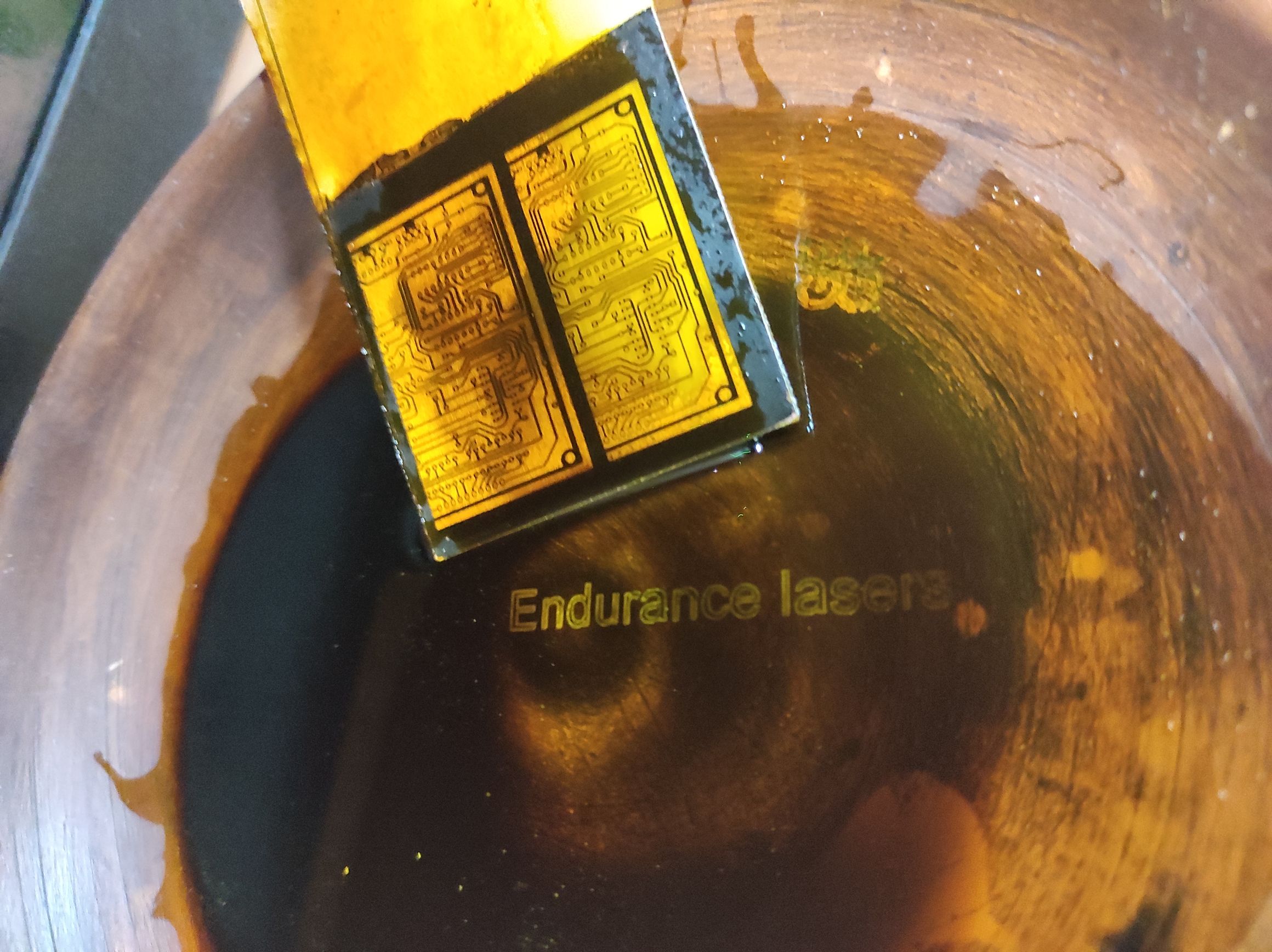

7. Put the glass fiber plate into the iron chloride water for 45-60 minutes.

The copper on the glass fiber surface, free of the film after the laser burning, will react with the iron chloride (copper etching chemical reaction) and goes into the solution leaving clean glass fiber in the contours of the inversion image.

Then, make holes for the necessary connectors with a small drill, or leave as is, and solder the connectors on top of the circuit board.

So, we have told you how you can create a small shop – laboratory for circuit boards manufacturing, using a 3D printer and a laser.

This technology is certainly not perfect and has several shortcomings, but it is efficient and can be used at home and small laboratories.

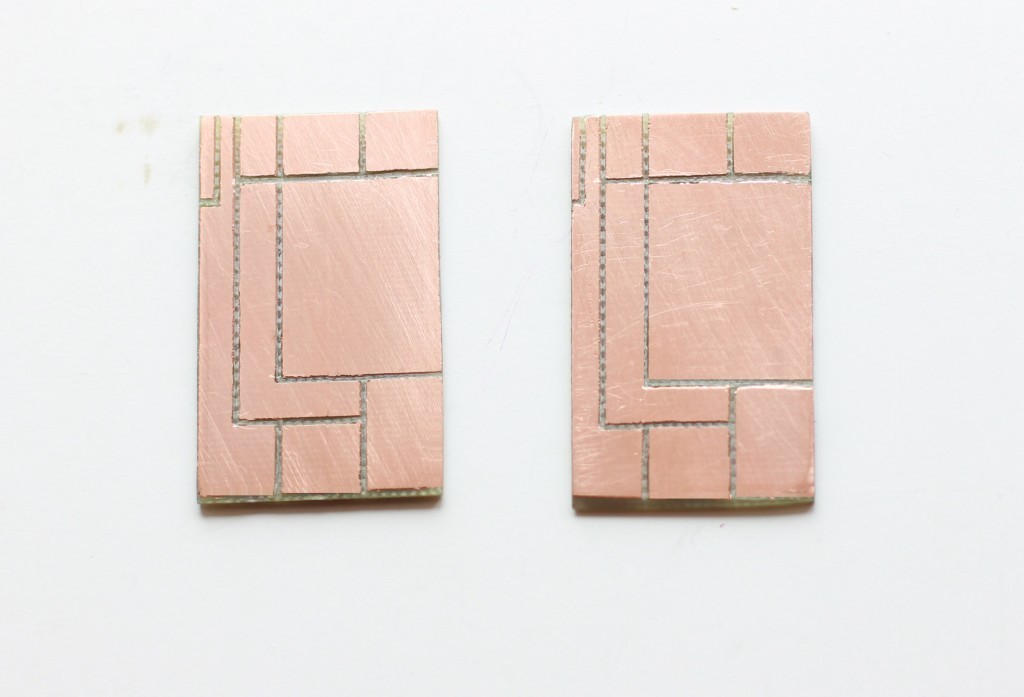

A DIY PCB made with the laser

CONCLUSION

As you can see, making A DIY PCB board can be made with your laser is a snap. With additional attempts, you will be able to create a more finely detailed PCB board.

With these instructions, we hope you can add making PCB boards to one of your skills and even begin putting some interconnected electronic components.

There are countless electronic PCB boards and you can make your very own. This is great for educational teaching and learning and well as a great way to add a skill for DIY enthusiasts. The creation of this DIY PCB board does not require many tools and all the materials are easily accessible and low cost. This gives new and experienced laser owners a chance to understand the capabilities of your laser’s abilities.

High-quality standard

Multi-level testing system.

Industrial components.

Ultra reliable

The guaranteed duration of the continuous operation ~48-72 hours.

True continuous power output

Our products have the rated power output as advertised – unlike Chinese analogues.

TTL mode

Can be turned on and off with 3.5-24V.

Variable power output.

Plug and play

Universal and compatible mount.

Compatible with most 3D printers and CNC machines.

Friendly return policy

Do not like the laser?

Simply return within 30 days and get a full refund.

Real-time advice

We assist and give advice by Phone / Email / Facebook messenger / Telegram / Whatsapp / Viber.

Professional support

We help to install and tune the laser. We offer qualified after-sales support.

Everything you need

We ship everything you need in one parcel to get started.

Immediate delivery

We ship all units within 4-24 hours. DHL express delivery allows you to get the package in 3-5 days.

Lifetime warranty

All our lasers are tested and could work up to 10000 hours.

Upgrade option

Do you have an old model? Upgrade your unit with more powerful one.