Looking for an advanced engraving / cutting system?

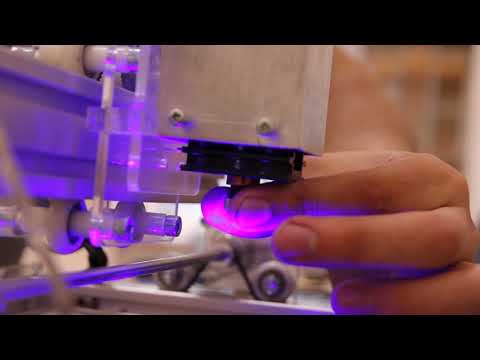

Do you already have a 3D printer or CNC machine?Order a 3-3.5 watt (3000-3500 mw) laser add-on for your 3D printer or CNC machine.

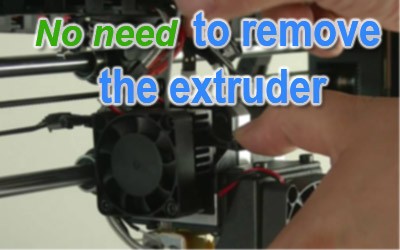

It takes only 15-30 minutes to install it.

Use the same software to create a g-code for engraving/cutting.

№1 customer support for 3D printer / CNC machine users.

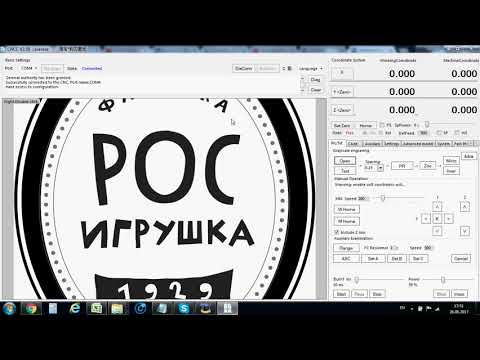

Use the same slicers you always use on your 3D printer: Cura, Repetier, Slic3r, Simplify3D or CNC software like Mach3, etc.

To prepare a g-code use an the Endurance plugins or the T2Laser software.

Buy and advanced 3 - 3.5 watt (3000- 3500 mw) laser today!

Did you consider to turn your 3D printer or CNC machine into a powerful and portable laser engraving or cutting machine? In 2015 Endurance invented a way to convert your 3D printer or CNC router into a cutting or the engraving machine with an Endurance diode laser add-on. The Endurance laser is the best upgrade for your existing 3D printer or CNC. Add to your 3D printing machine and ultimate ability to cut and engrave.

With a 3.5 watt Endurance diode laser you can engrave faster and cut deeper such materials like plywood, wood, acrylic, cardboard, hardboard, felt, leather, plastic (ABS, PLA) and many more.

The 3.5 watt (3500 mW) diode laser is a powerful and advanced laser to upgrade your 3D printer or CNC router with and is able to create beautiful engravings and laser cuts. It is very easy to install and does not require any special knowledge. It can be installed on almost any 3D printer or CNC mill. If you have any issues during installation or operation, we are always available to lend a hand. We provide the ultimate customer and after-sales support!

With our laser, you can engrave and cut a variety of materials such as

- plywood / wood

- acrylic

- PLA / ABS

- felt / fabric / fiber cloth / leather

- paper / cardboard

- hardboard / MDF

- stone

- glass

- painted aluminium

- and some others

Everything that you need to know about Endurance accessories.

- Goggles

- always wear red or green goggles when you operate the laser. Remember Endurance lasers are class 4 item and must never be aimed in any live specie.

- G2 lens

- short focal lens with focal range 2-10 mm (1/10 - 2/5’’) a necessary accessory for laser cutting or laser engraving on metals.

- Endurance MO1 PCB

- an electronic board that allows feed the laser from external power supply (needed when your main board does not have enough power output)

- Laser connectors

- variety of a different wires and connectors that will be useful when you plug the laser to your board.

- Laser mounts

- aluminum mounts that will help you to hook the laser to you machine. 4 types with M3 screws: L, П, I, T.

- Laser actuator

- a Z axis actuator that will help to change laser position on Z axis. Is a good option for XY plotters with no Z-axis mechanism.

- AC/DC 12V5A

- an additional power supply for Endurance lasers.

- AC/DC 12V1A

- an additional power supply for 10 watt laser fans.

- Step down DC/DC converter

- a DC/DC converter that decreases the voltage down to required 12V for Endurance lasers.

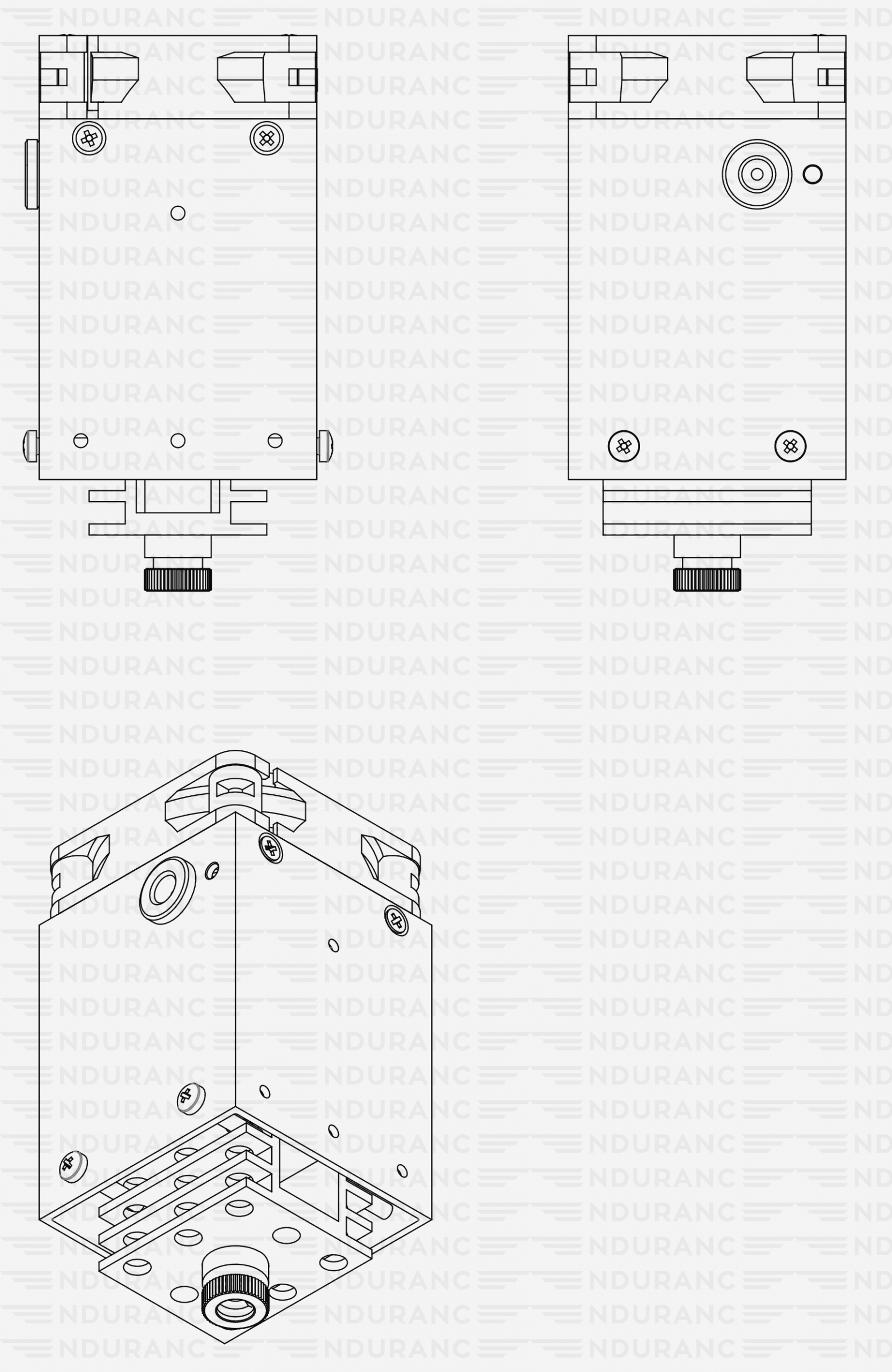

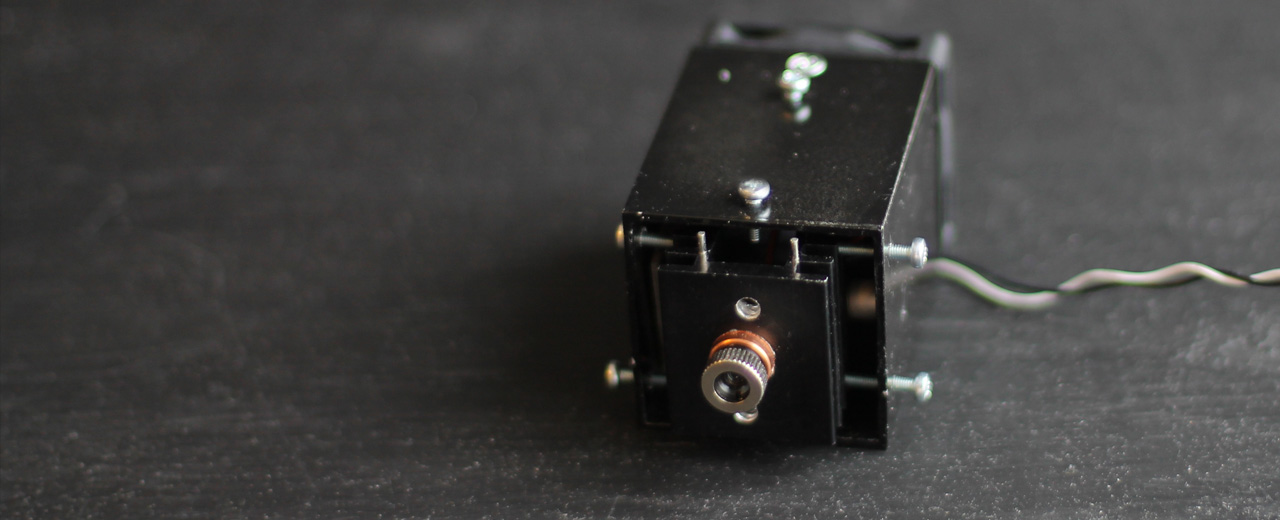

- Endurance laser box

- is a nice gadget (add-on) for your laser module to measure incoming voltage, outcoming voltage and current on a laser diode, laser driver module, Endurance MO1 PCB, temperature sensor and Arduino board for changing laser power.

- Arduino board with an Endurance sketch

- allows changing laser power (duty ratio) and a frequency of the laser. Can change the laser into impulsive mode.

- Temperature sensor

- additional temperature sensor for monitoring of a laser temperature.

- Voltmeter

- additional voltmeter for measuring incoming voltage.

- Voltmeter & ammeter

- additional voltmeter & ammeter for measuring outcoming voltage and current that goes to the laser diode.

- DIY checking pin kit

- a full it that will help you to check pins on your board, laser power, etc.

- Air pump

- laser addition that allows blowing the air to the place of laser cutting / laser engraving. Increases speed of a laser cutting up to 50% and reduce charring.

- TEC module

- Peltier cooling system for better laser cooling (increases power up to 10%).

The 3.5 watt (3500 MW) diode laser is very easy to install on almost any 3D printer or CNC machine using compatible mounts for the Prusa i3, X-Carve, Creality3D CR - 10, Wanhao Duplicator i3, Ultimaker, RepRap, Magnum, Prism, Makerbot Cube, Picasso, Hercules, SolidDoodle, Original Prusa i3 MK2, BCN3D SIGMA, Form 2, PowerSpec 3D Pro, ORD Bot Hadron, Zortrax M200, Kossel, FlashForge Creator Pro, CEL Robox, FDM and others. If you have a printer not listed, please contact us and we will make a custom mount for you.

Our lasers are very easy to operate using standard software and run on the existing 9-16 Volts of your printer or router.

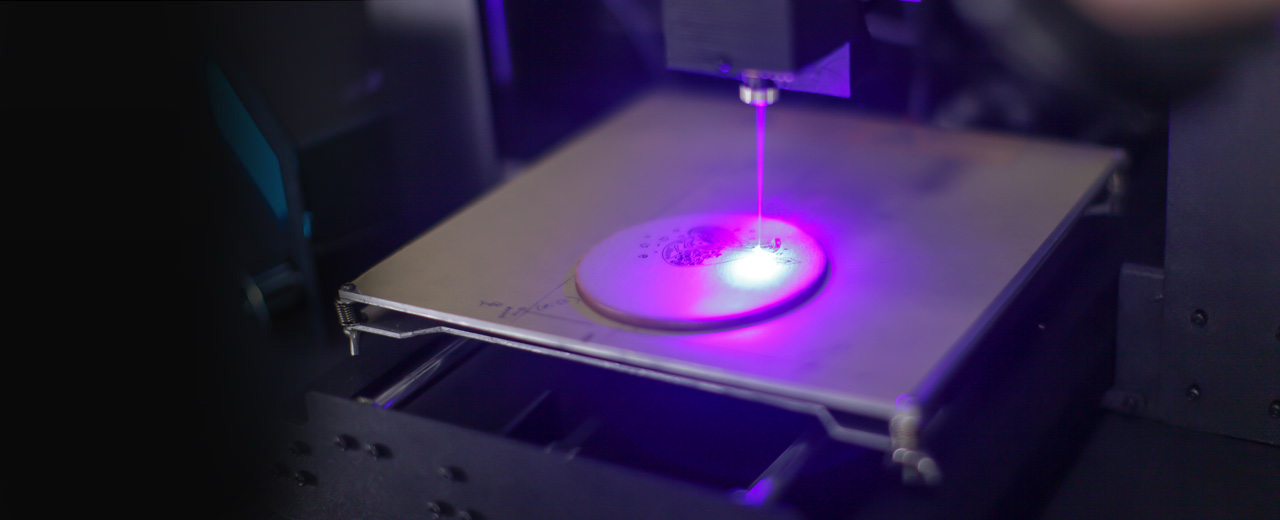

In order to create a laser engraving or a laser-cut with our 3.5 watt laser all you need to do is put the piece you want to cut or engrave onto the worktop. Just convert a jpeg image into a vector image and then convert it into g-code. Use software like T2 laser or Inkscape + plugins to create a g-code you need. Start the machine and enjoy watching it do its job. If you have any questions we will be happy to assist you any time. Just contact us via email or on our Facebook page.

A 3.5 watt laser can cut up to 3-4mm of wood and plywood.

Useful videos

The 3.5 is great. Hope

The 3.5 is great. Hope to go even bigger soo

hello everyone, not knowing anything

hello everyone, not knowing anything about laser I found myself in a YouTube movie of the Endurance Laser

I was immediately involved in the clarity of the descriptions and

In the end I chose a 3.5 watts although it is at the hobby level I regretted not taking at least an 8 watts ; anyway to start it’s okay so

it was a great choice: I thank George for his patience and for his help always timely and very useful. Congratulations

Oriano Ghigna

I recently purchased the 3.5W

I recently purchased the 3.5W Laser integrated with the DIY Engraver from Endurance, to replace a slow 200mW Toy from China. After 100+ Engravings, i can say that overall Engraving Time on Wood improved up to 10 Times, compared to my old Laser. Quality of the Engravings is very good, assuming proper focusing of the Laser Beam. I did not try to engrave Stone yet, but i am pretty sure it will work, but i plan to buy a more powerful Module/Engraver from Endurance later on, for advanced Purposes.

My 3.5W Endurance laser arrived

My 3.5W Endurance laser arrived yesterday. Just like plug and play. George was very patient and professional with all my inquiries. I’m a newbie in this area and with the videos and George’s help it almost looked like I knew what I was doing. I’ll be back when I’m ready for a 10W!

Thanks George!

The price performance ratio of

The price performance ratio of the laser is very good. I had a bit of a difficulty to get is started, because the documentation is a bit shallow, but George replied very fast to all questions and even created a small tutorial video for the first setup.

I highly recommend Georges’s products and his support.

Endurance 3.5 Watt Laser

Endurance 3.5 Watt Laser

This is a 5 Star Laser Diode, its very easy to install on any machine having tried it both on my Prusa A8 3D printer and my MPCNC homebuilt CNC machine.

My current project was using the Laser Diode to cut 3mm – 3.4mm Plywood, this laser has no issues cutting through this material in several passes.

If you are looking for a simple laser to setup for cutting wood under 3mm thick this is the laser for you, it also cuts through 1 mm Balsa wood in 1 pass, so this laser would be great for model makers and hobbiest, my current use will be for model ship building.

Also the support and communication from George is very good answering any question I had.

Kane

Sometimes 13N10 or LM338 die and need to be replaced. We will guide you how to do that.

- use a G-2 lens for laser cutting.

- setup a perfect focus on a G-2 lens (make sure that focal range is something like 4-8 mm)

- make sure that a plywood is very dry (you may use a 3D printer bed to warm it up)

- speed parameters should be 50-150 in your g-code

- make sure that the plywood is not specially treated with anti-inflammable materials

- make sure that the laser runs full power and you have enough power that goes to the laser

- make sure that the lens is clean and has no dust on it.

Bitcoins and Litecoins

Bitcoins and Litecoins