Statement of the problem: To obtain colors and a color pattern on stainless steel using a 1064 nm 50 W laser ” Raycus RFL-P50QB”.

To complete the task, a 50W laser marker was used , which consists of 4 Endurance DIY marking components. machine , laser, galvanometer and lens.

Endurance DIY marking machine, in turn, consists of a table, a block on which a galvanometer is installed, and a module for connecting a pulsed fiber laser to a galvanometer.

The laser has a wavelength of 1060-1080 nm , with an average power of 50 watts. The pulse duration is 120-150 ns . The laser frequency range is 120-150 kHz (Figure 1).

Galvanometer RC 1001 with a lens ” SL -1064-112-163 G ” installed on it, having a focal length of 163 mm and a working area of 112 mm by 112 mm. maximum speed 8000 mm/ s (Figure 2).

The machine is also equipped with lifting legs, with which you can raise and lower the unit. The travel range is 121 mm. With frequent changes in the height of the processed object, it is suggested to use a lifting table. The general view of the installation is shown in Figure 3.

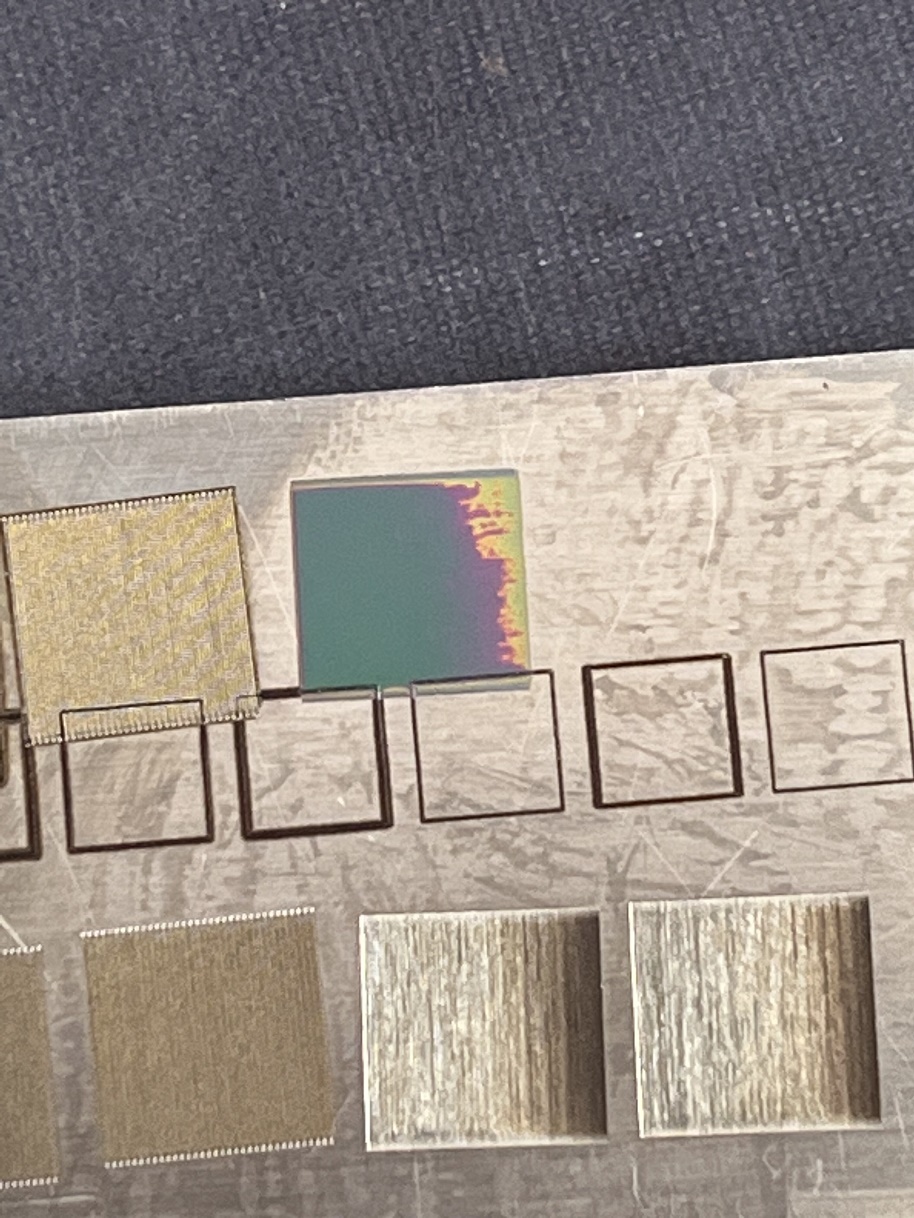

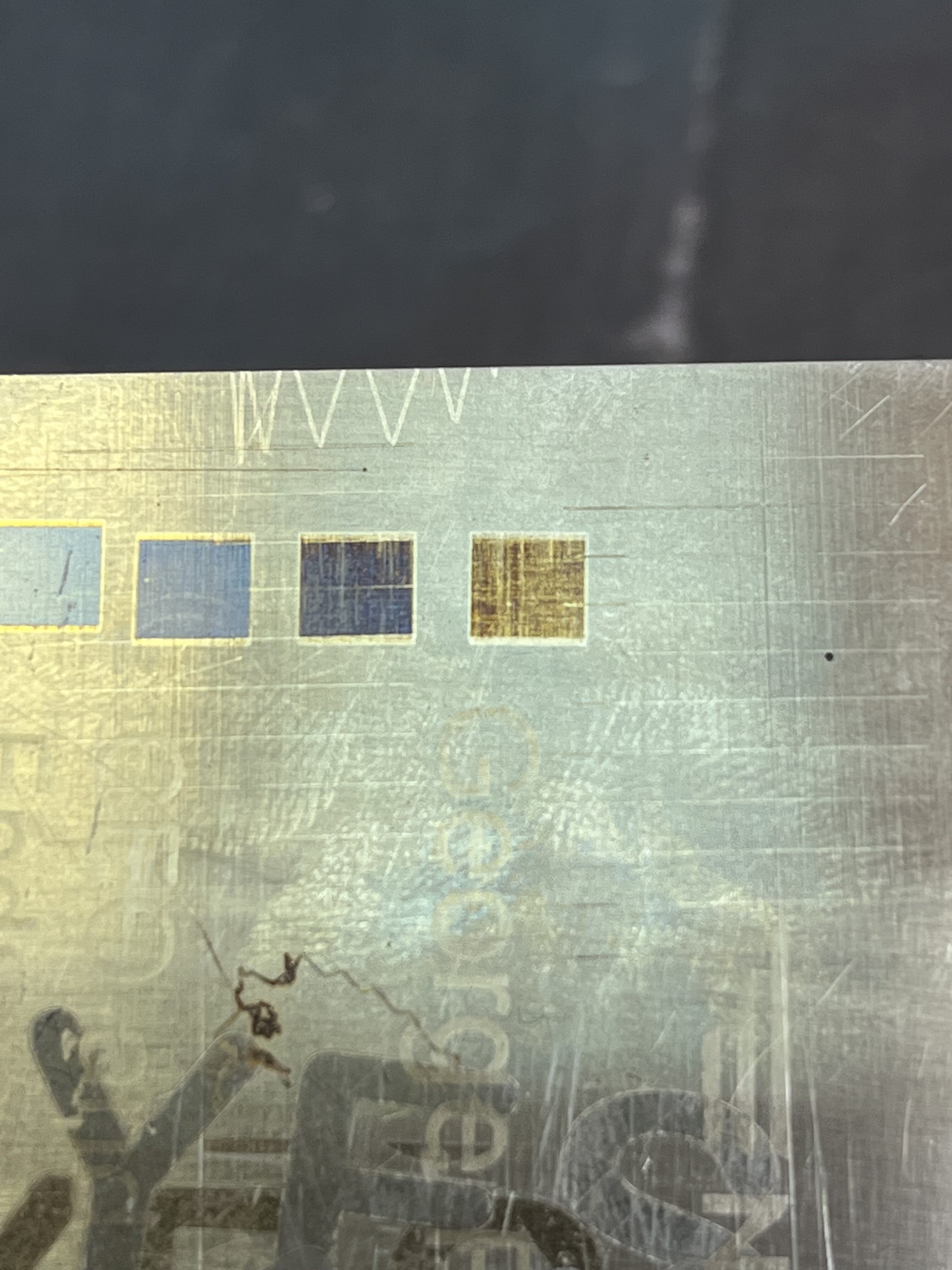

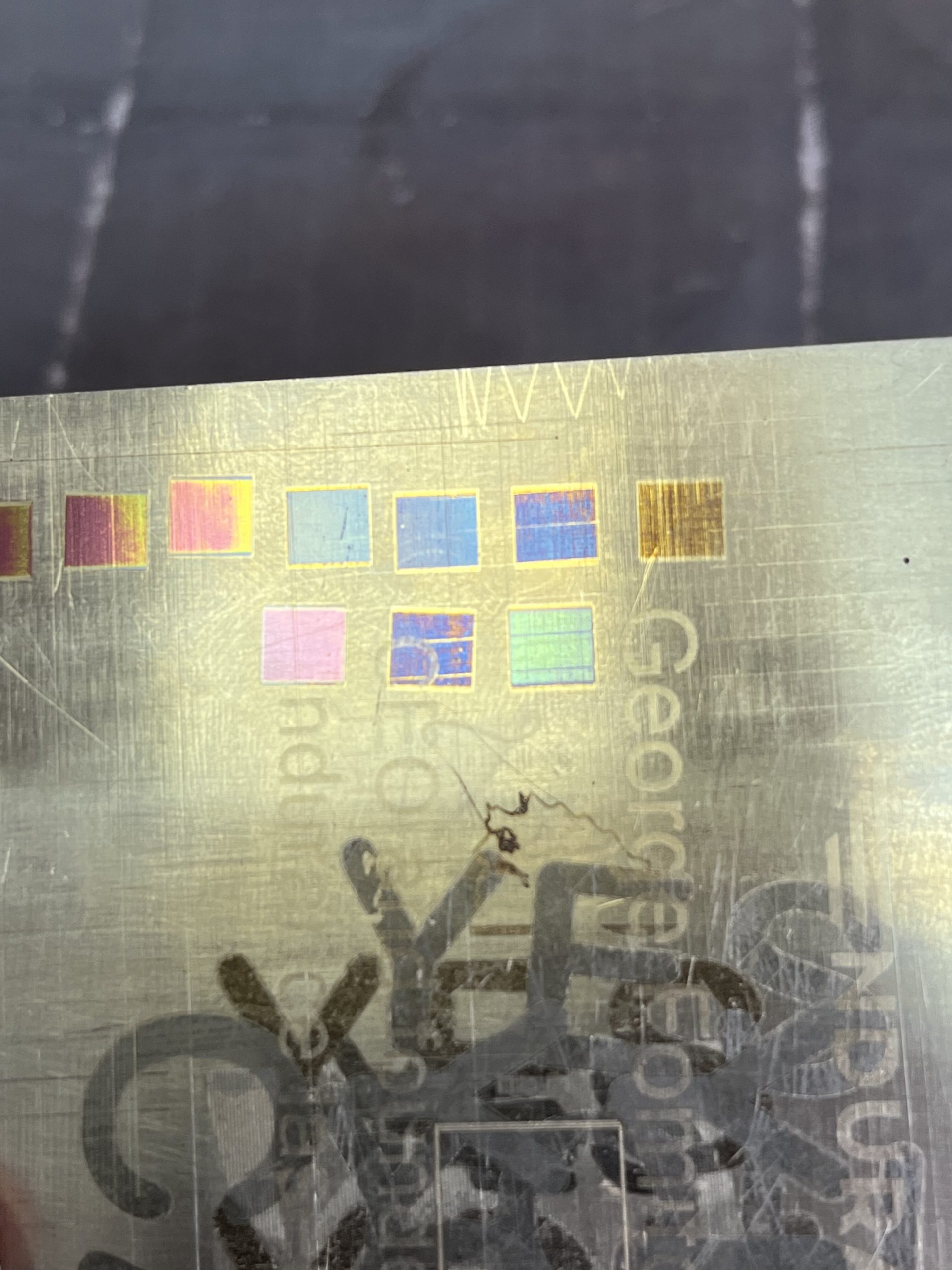

During the tests, the parameters were indicated at which the appearance of tint colors is observed. Since tint colors occur most often during oxidation, as a result of the heat treatment of metals, knowing that with an increase in the heating temperature of the plate, the colors change from light straw (300 ° C) to blue (700 ° C), we assumed that it was possible to control the degree of heating of the plate by changing the fill density.

The parameters are as follows:

- Power: 35%

- Speed: 40mm/s

- Frequency: 50Hz

Changeable parameters with which colors are obtained on the surface of the plate:

- Focal length

- Fill Density

- Repeat overlay

The height of the lift during the experiment varied in the range from 65 mm to 75 mm.

Laser operation parameters for obtaining a color image by modes:

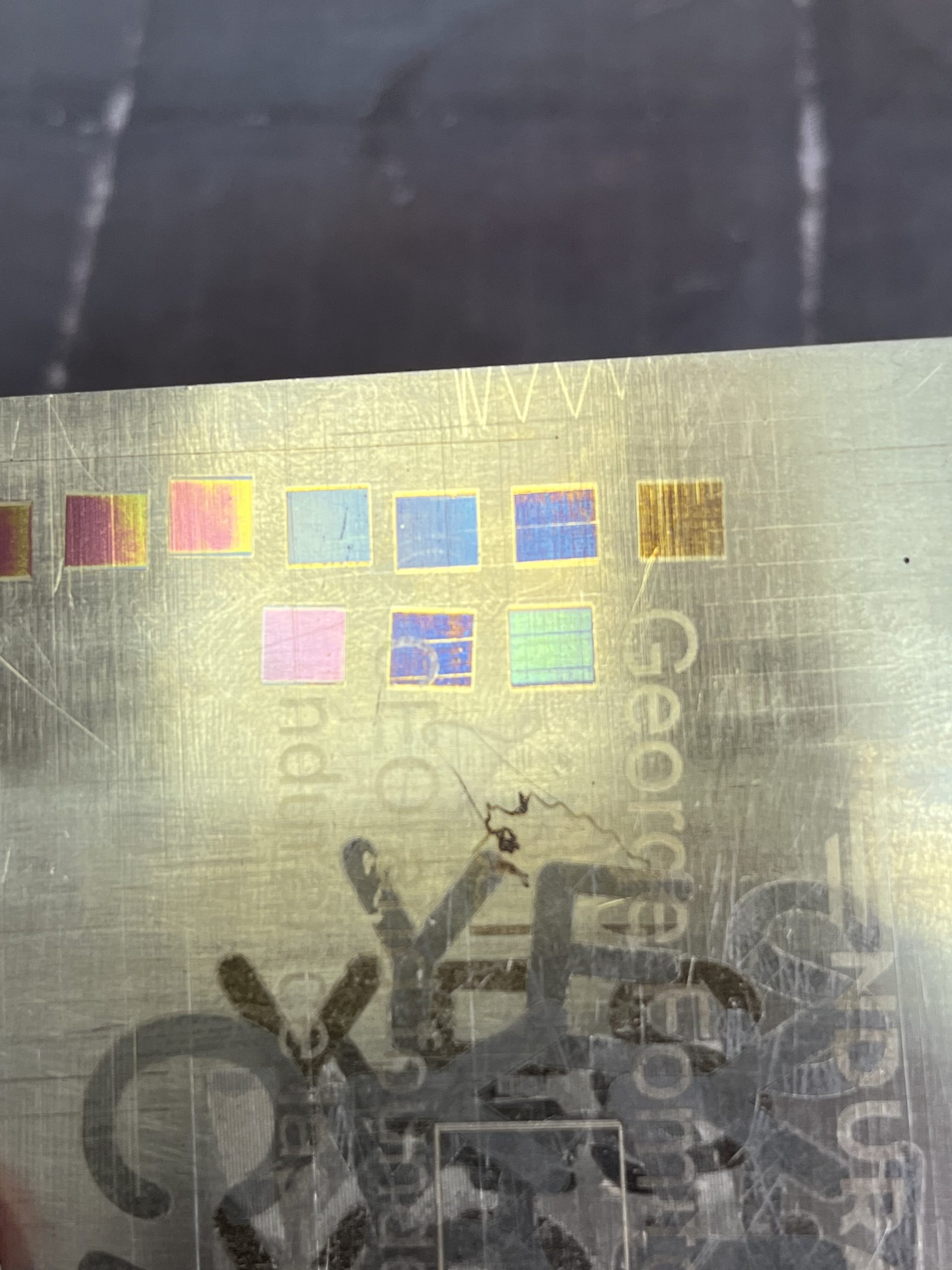

Pink – yellow:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.013mm

- Number of repetitions: 1

Grey-blue:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.023mm

- Number of repetitions: 1

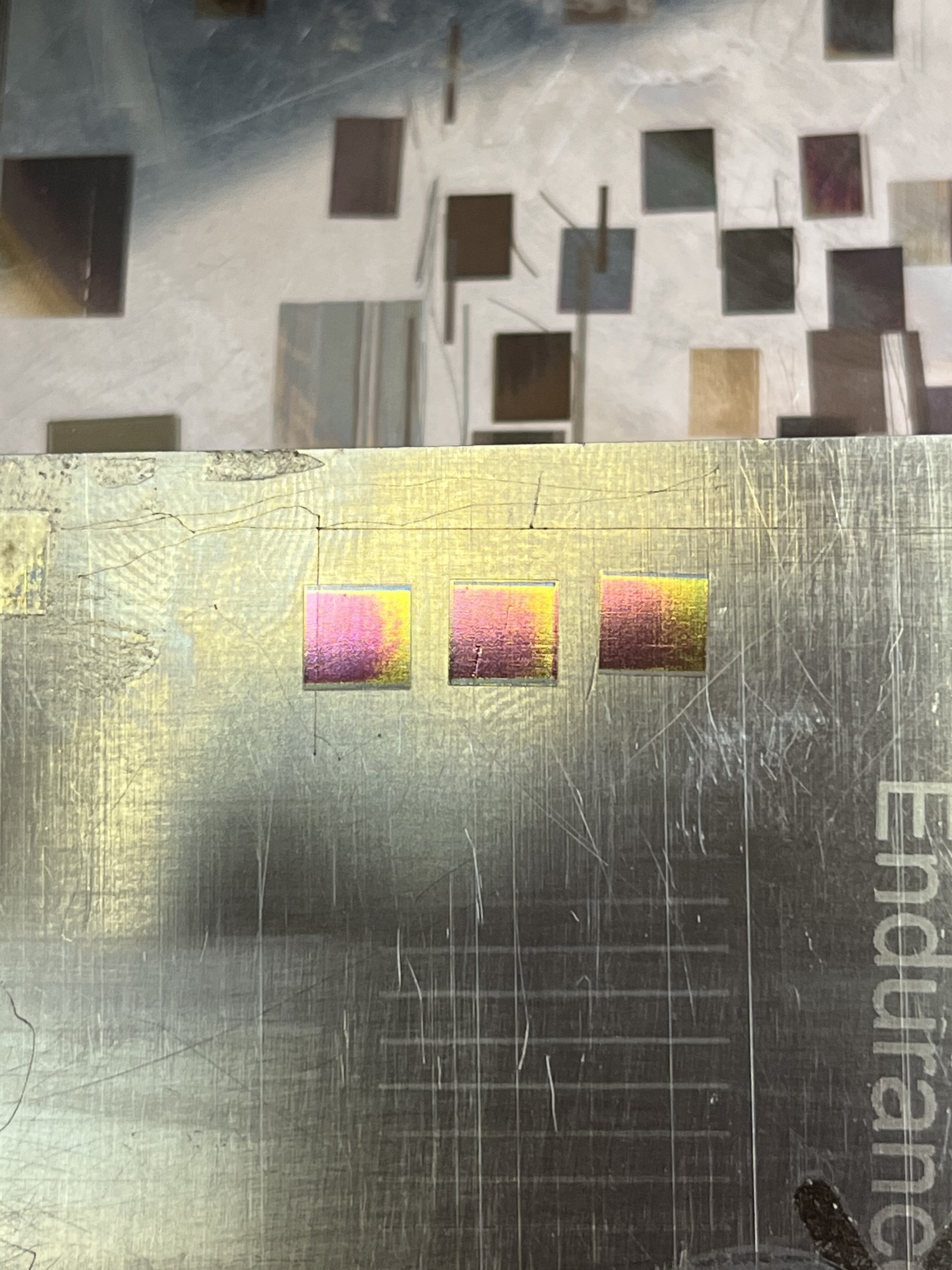

After two and three repetitions with the same parameters, the following colors were obtained:

Blue:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.035mm

- Number of repetitions: 2

Blue:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.035mm

- Number of repetitions: 3

Camel:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.043mm

- Number of repetitions: 2

Lilac:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.013mm

- Number of repetitions: 2

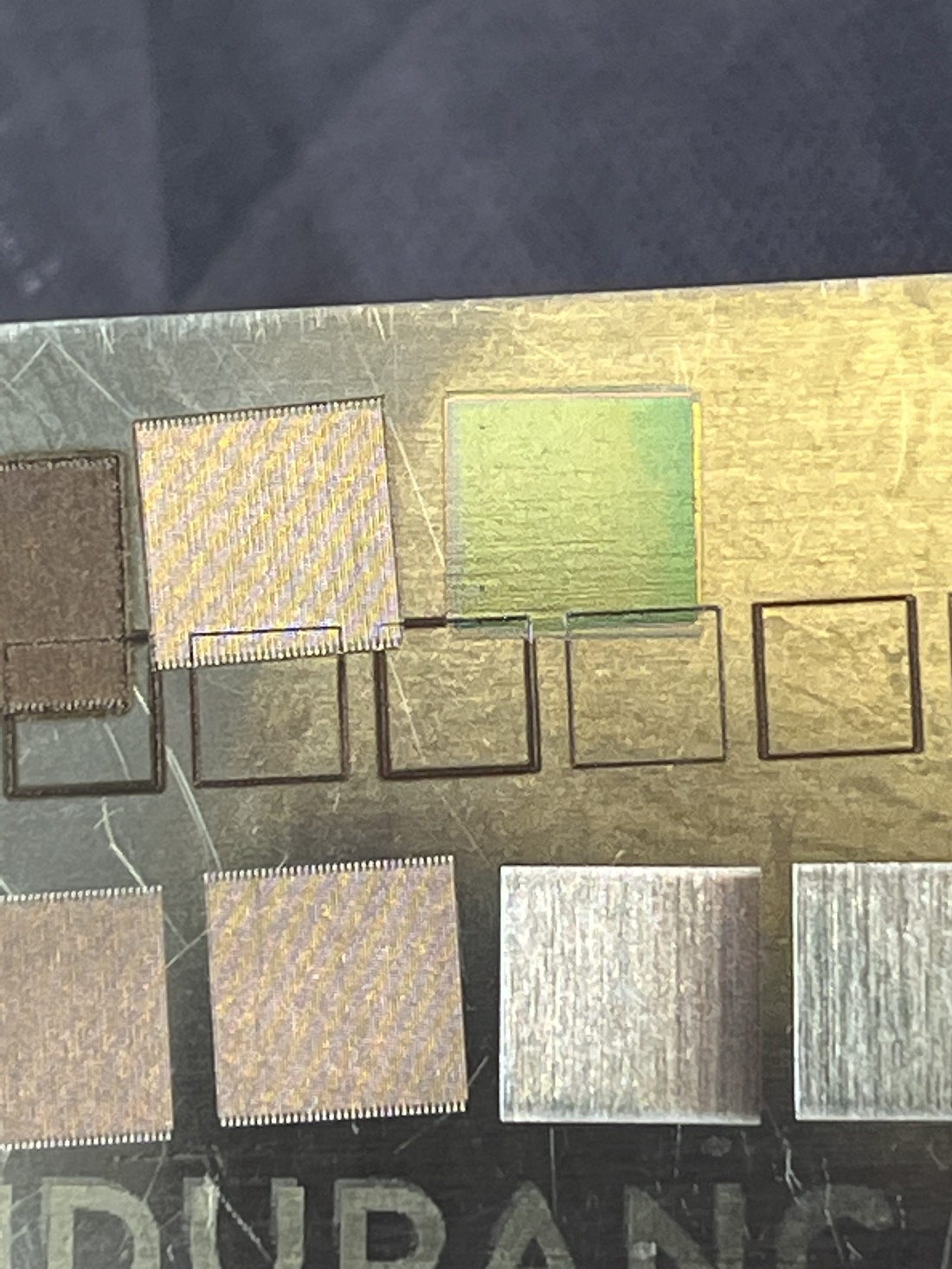

Lime:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.013mm

- Number of repetitions: 3

light green:

- Speed: 33mm/s

- Power: 30%

- Frequency: 60 kHz

- Fill Density: 0.003mm

- Number of repetitions: 1

Dark purple:

- Speed: 50mm/s

- Power: 20%

- Frequency: 50 kHz

- Fill Density: 0.013mm

- Number of repetitions: 4

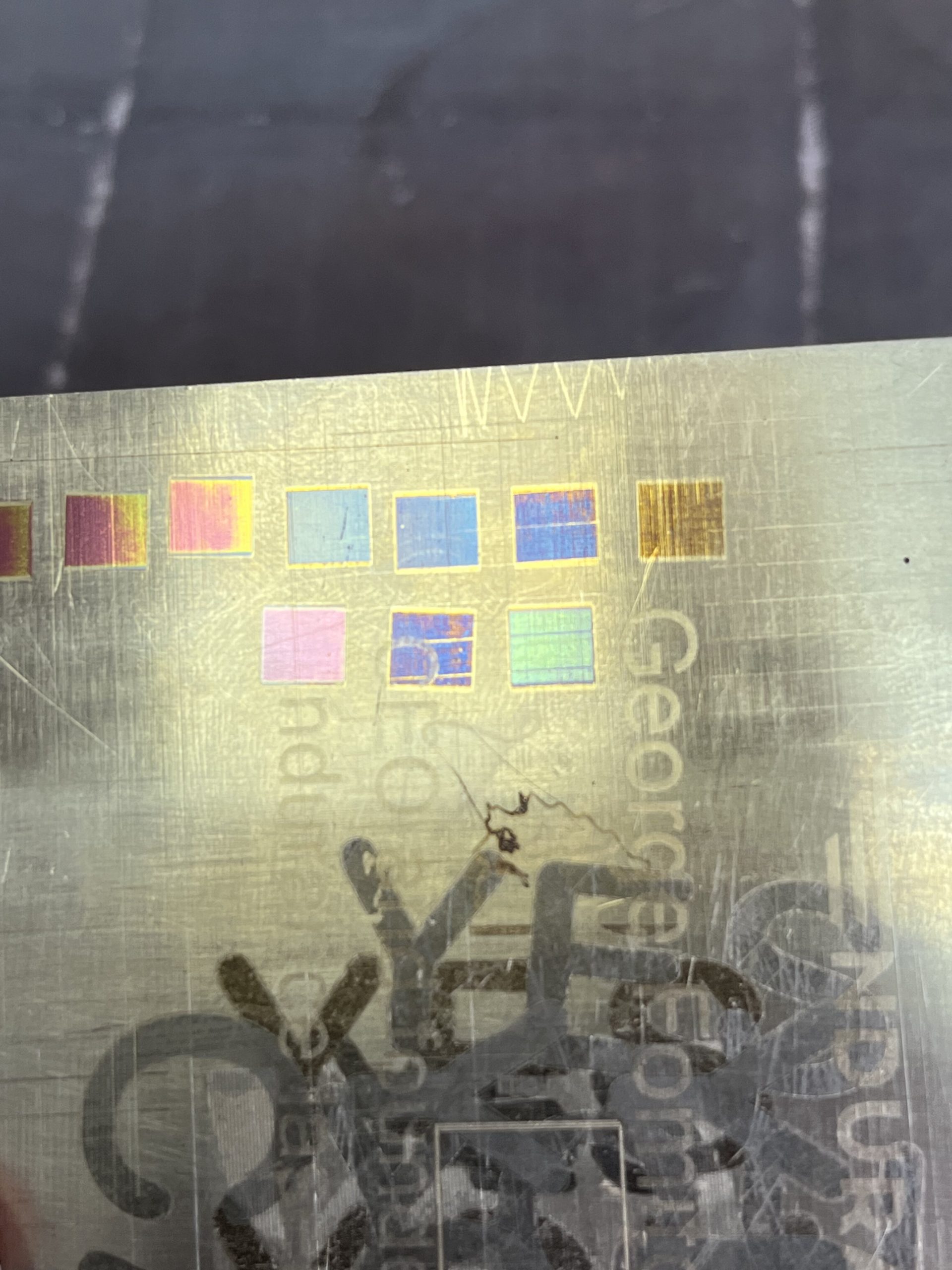

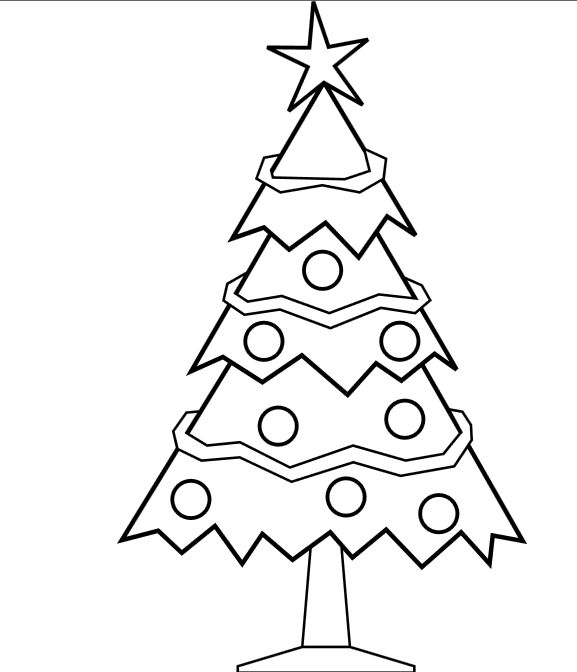

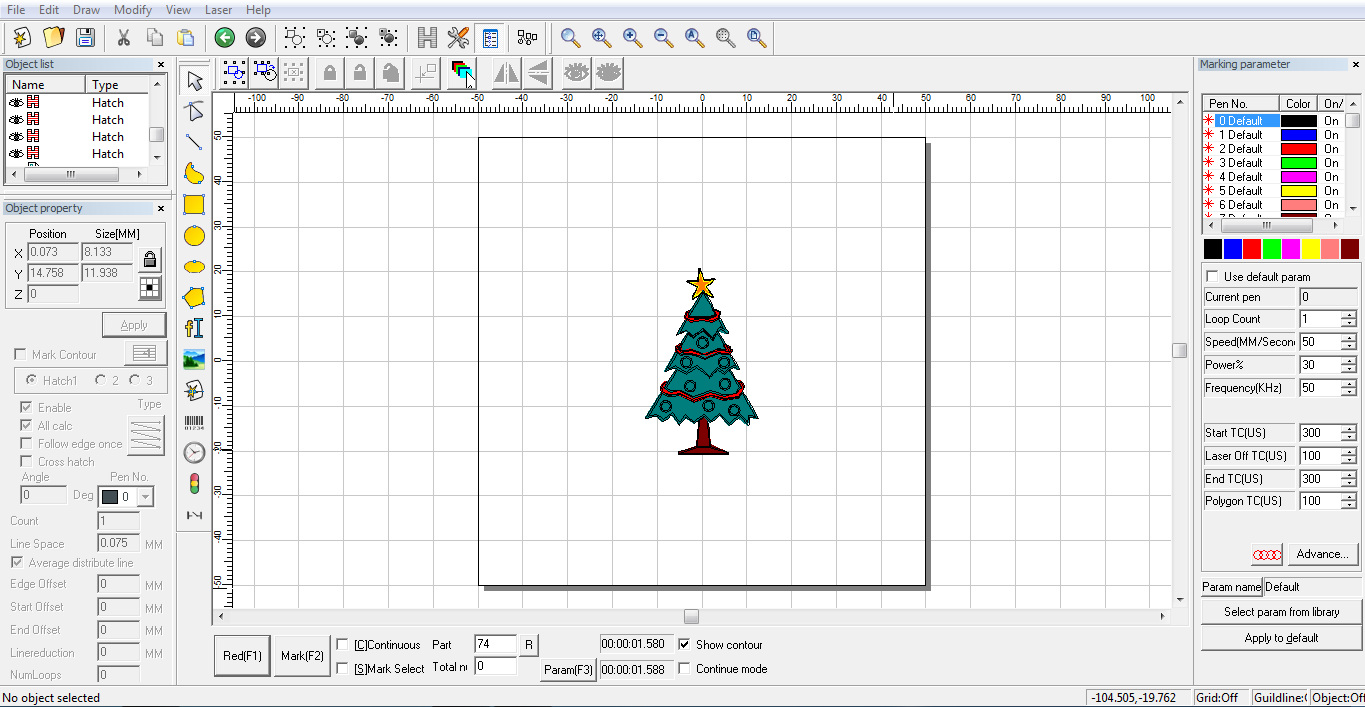

The second task was to apply a pattern on a titanium plate using 50 W pulsed fiber laser ” Raycus RFL-P50QB”. To do this, we processed the vector image (Figure 14) in the Abode program. Illustrator and separated it into layers. In the EzCad program (Figure 15), for each layer, the parameters given above were set (The colors shown in the program do not correspond to those that will be used in further engraving and are used only to indicate the layers).

The result was the following image:

The work done shows that with a 50W Raycus fiber laser you can get colors on titanium, as well as create color drawings on it.