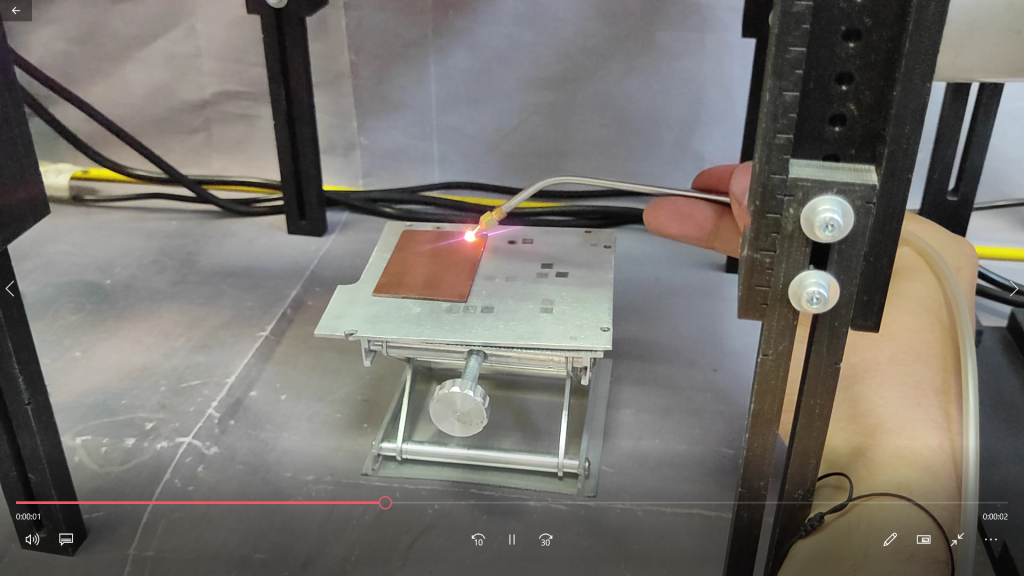

Laser drilling of the fiberglass with 50 watt Endurance Lasers laser (Raycus laser source).

Watch a video guide!

Statement of the problem: it is necessary to make drilling (holes) in copper-plated fiberglass for further work with fiberglass.

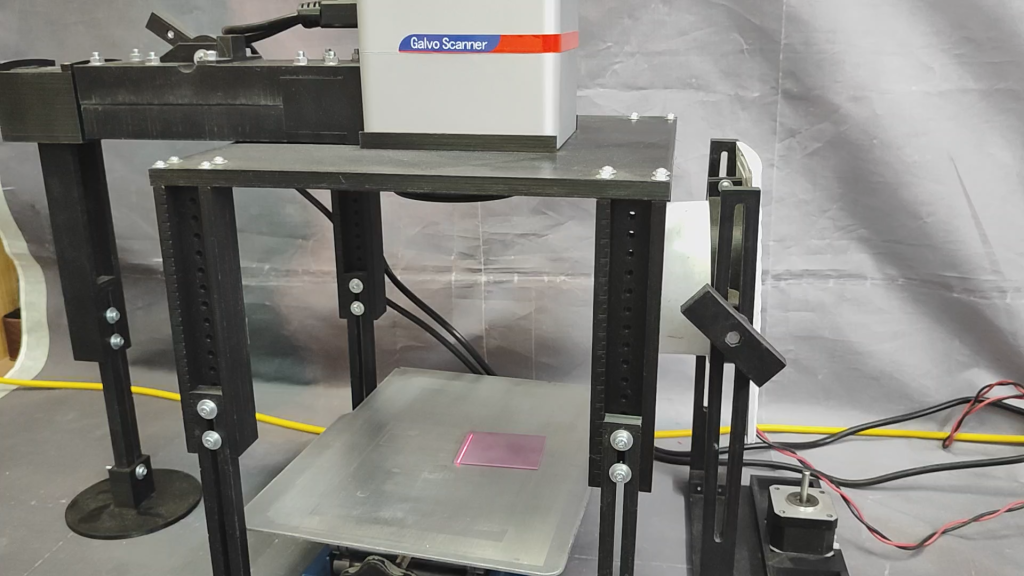

Holes were made with Endurance DIY Galvo 50W imported 1064nm long wave laser installed in Galvo Scanner RC1001 with a conventional Theta lens with a working field of 100 x 100 mm. Galvo ‘s top speed Scanner a 8000 mm / s, a cooler is used to blow off combustion products. A computer is used for control.

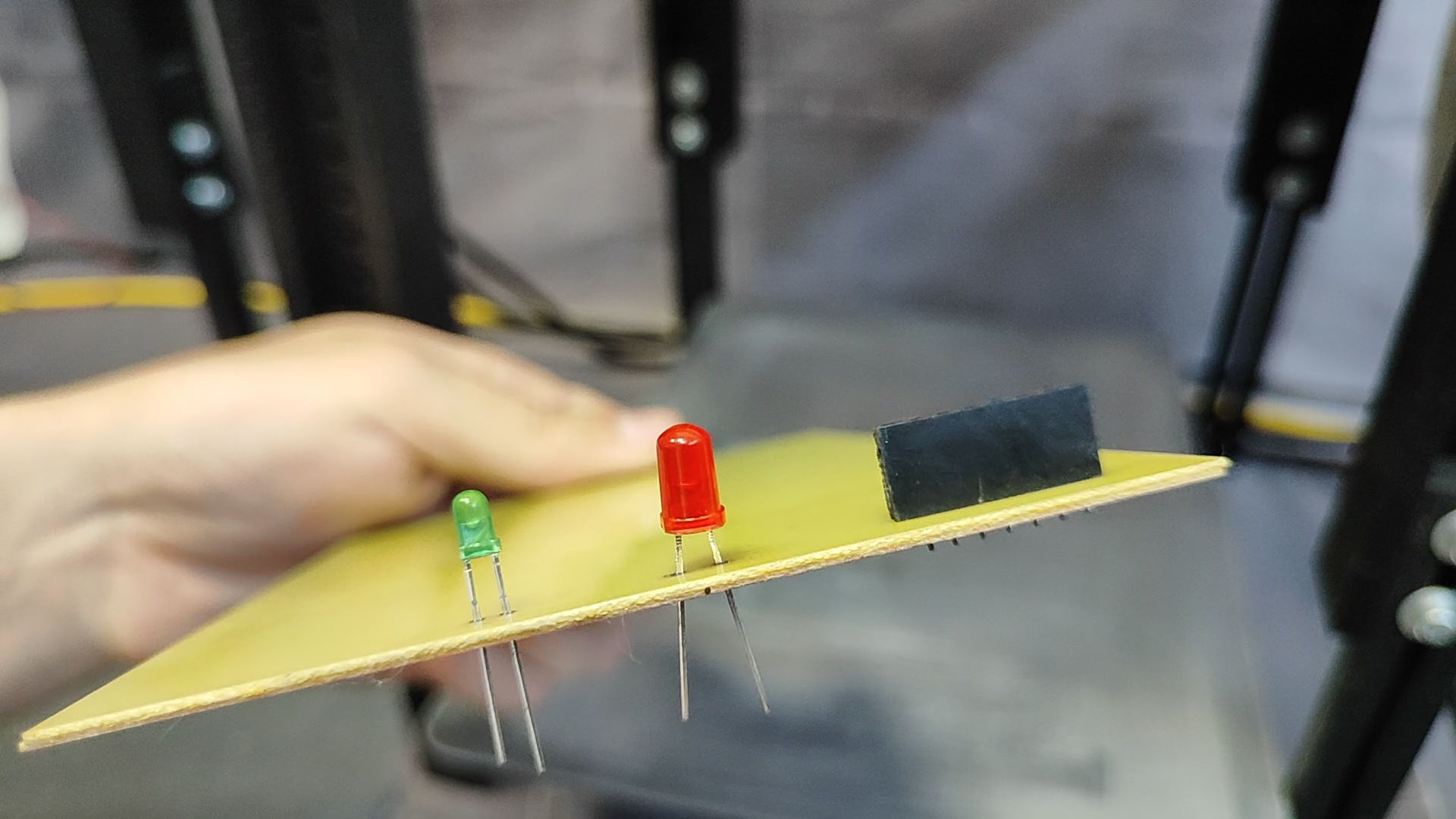

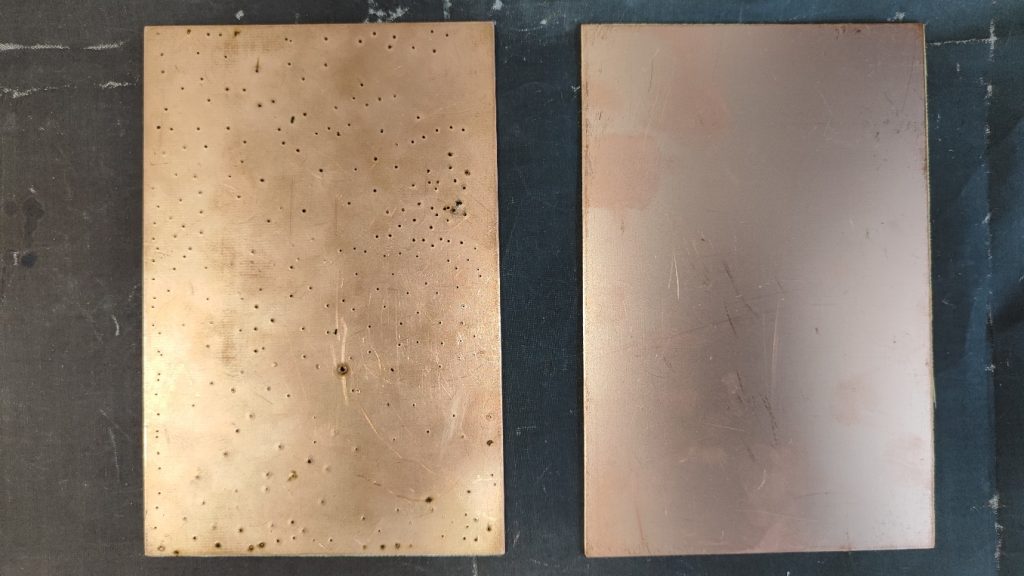

The holes were made on two different plates. One plate measuring 150 mm by 100 mm and 1.3 mm thick with an apparent copper layer on one side.

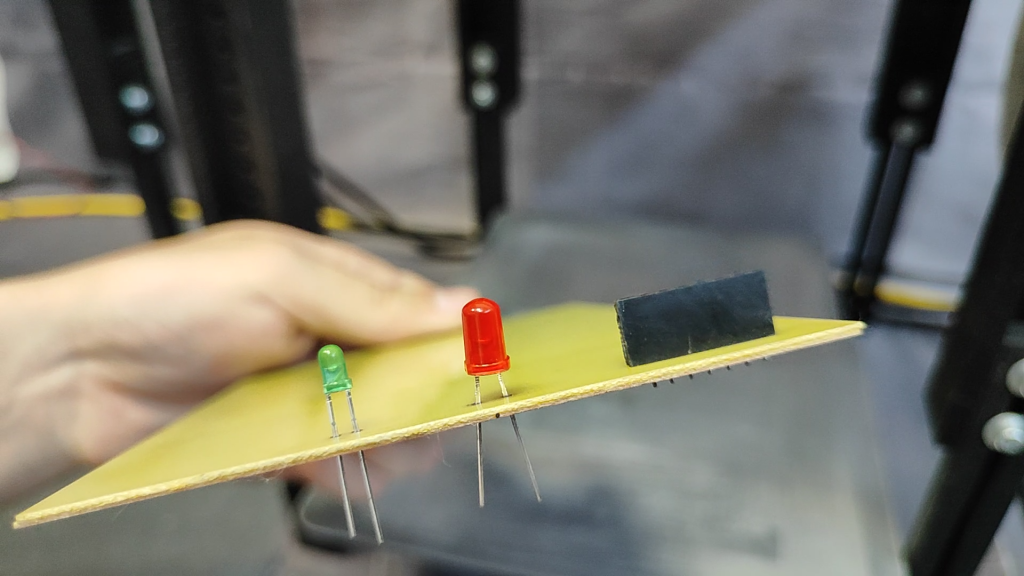

The second plate measures 35 mm by 55 mm and is 1 mm thick with an exposed copper layer on both sides.

The holes were made with a diameter of about 0.6 mm. Good for attaching DIP components .

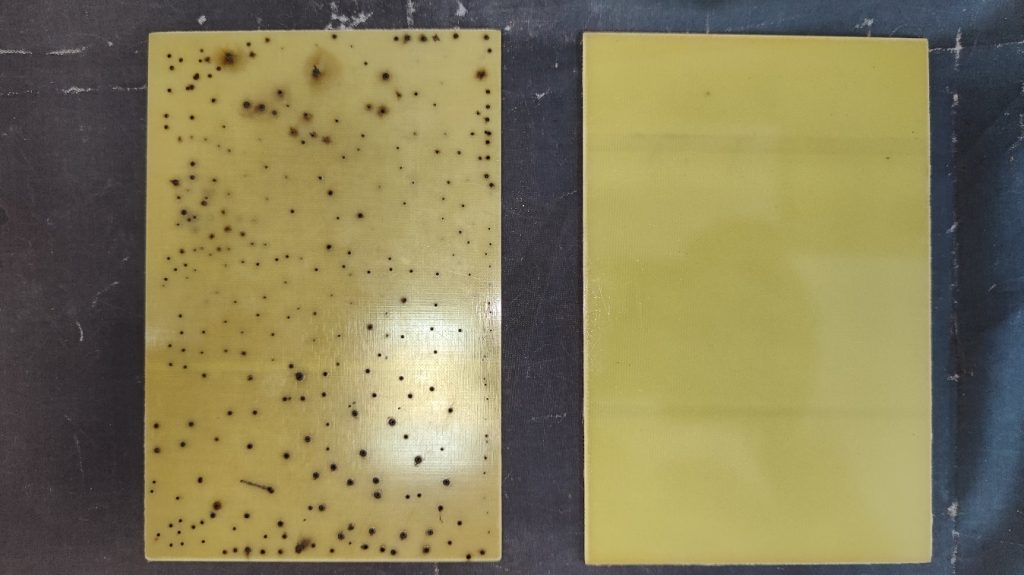

First exhibited speed more. If you set 150 repetitions, speed 700 mm / s, power 91% and frequency 60 kHz, then extensive charring with defect phenomena will be observed.

Then a significant number of repetitions and a low speed began to be exhibited. The parameters were set as possible: 1, speed 2 mm/s, power 96% and frequency 50 kHz. The result compared to the maximum speed (700 mm / s ) became much worse.

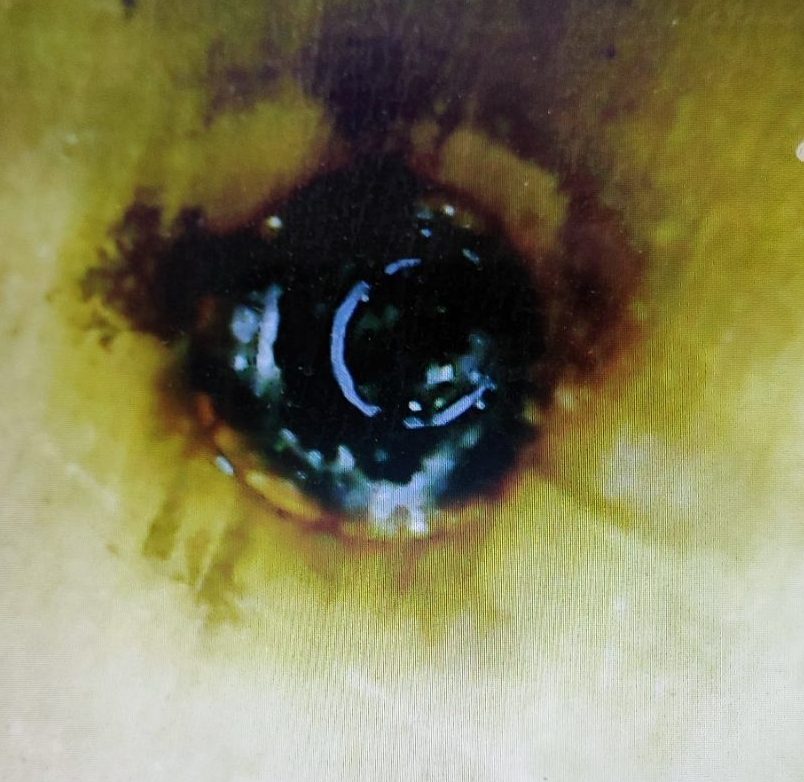

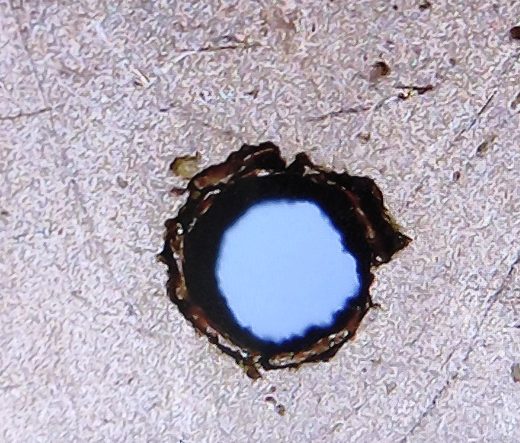

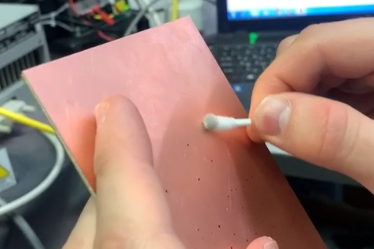

You must use ethyl alcohol or white spirit along with the target and other rod in order to remove carbon deposits from the outside and inside. Subsequent photos taken after stonecrop from soot.

In the case of everything with a plate of accessible copper layer on one side, the best result was obtained when the hole was made from the side of the copper layer.

Hole when work was done from the side where there is no copper layer:

Hole when work was done from the side where there is copper:

The optimal parameters are 25 repetitions, speed 130 mm/s, power 100% and frequency 65 kHz. Significant charring of the inner hole occurs. With side plates around the holes there is a minimum amount of burn marks. The results are optimal for both inserts .

Result with the copper-plated board on one side:

The result with a board with copper plating on both sides:

Holes were opened for several DIP components. Hold securely.

We decided to improve the results of the experiment by using the inert gas C02 during the cutting process. The fact is that as a result, airflow will occur: cooling and removal of combustion products, as well as due to the inclusion of inert gas, the oxidation process will occur in the waterfall, because. “torch”, which is formed by a laser pulse, incl. mirror marks on the surface of the material.

If you use a compressor to increase the blowing of the place where the air is blown, then the result does not increase, the “torch” and soot will be blown away in the opposite direction from the nozzle. If Co2 gas is used, the result will not improve either.

Using gas a Co2 inert gas

The result of drilling fiberglass with Endurance DIY Galvo 50 watt laser can be called acceptable for solving small problems associated with the manufacture of experimental boards. In the case of everything with the plate, the copper layer was opened on one side, the best result was obtained when the hole was made from the side of the copper layer.

In the case of the detection of a plate with copper plating on one side and on both sides, to the result of a cardiac, different thickness of the plate to no defeat on the result. Residents with noticeable defects. You must use ethyl alcohol or white spirit along with the target and other rods in order to remove carbon deposits from the outside and inside. Then you can work with the product.