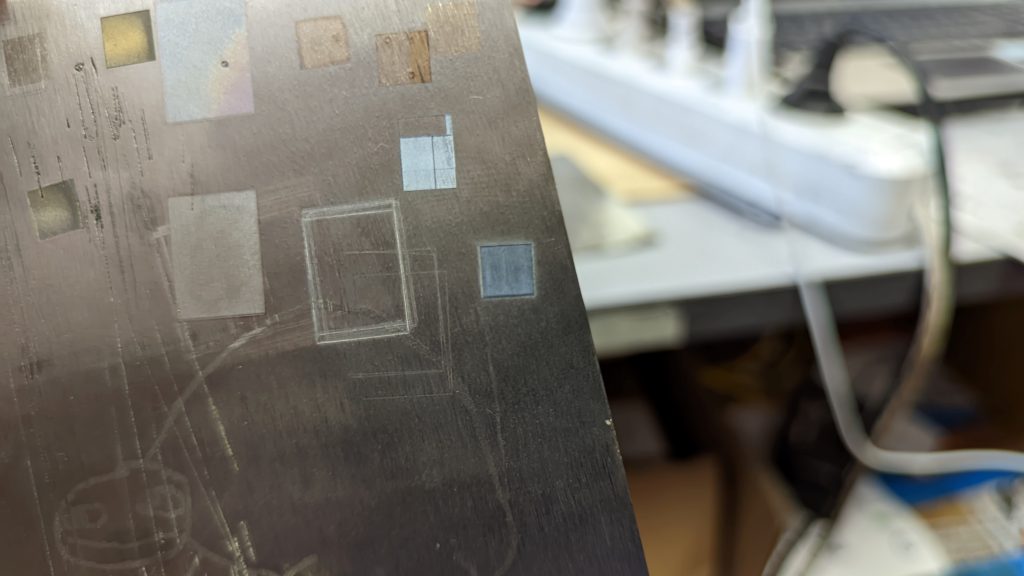

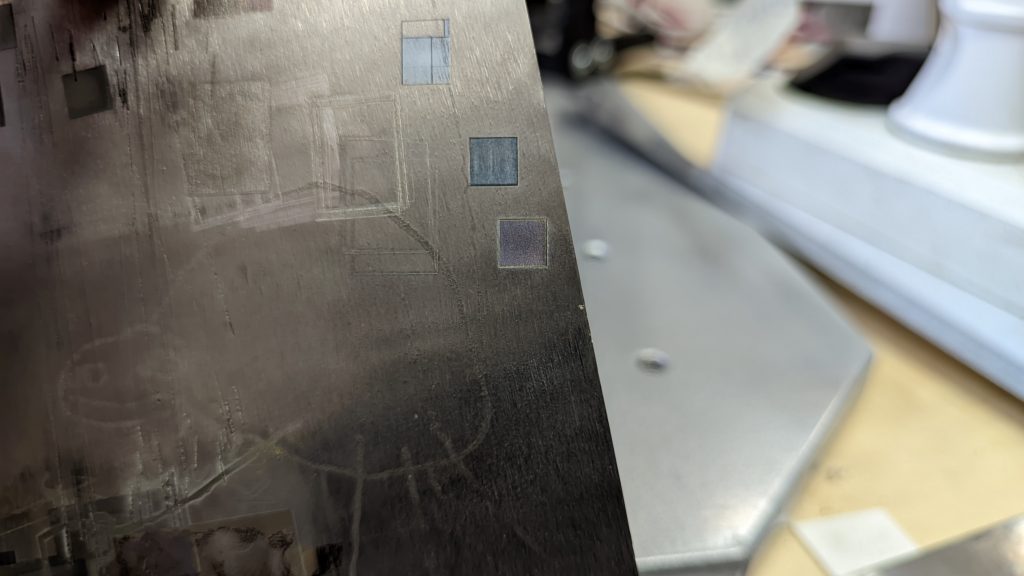

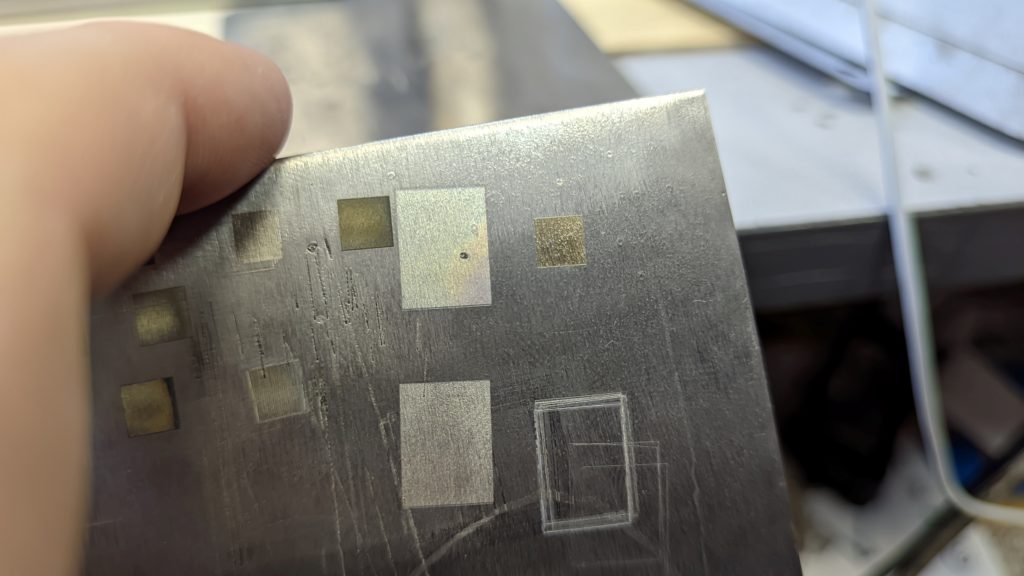

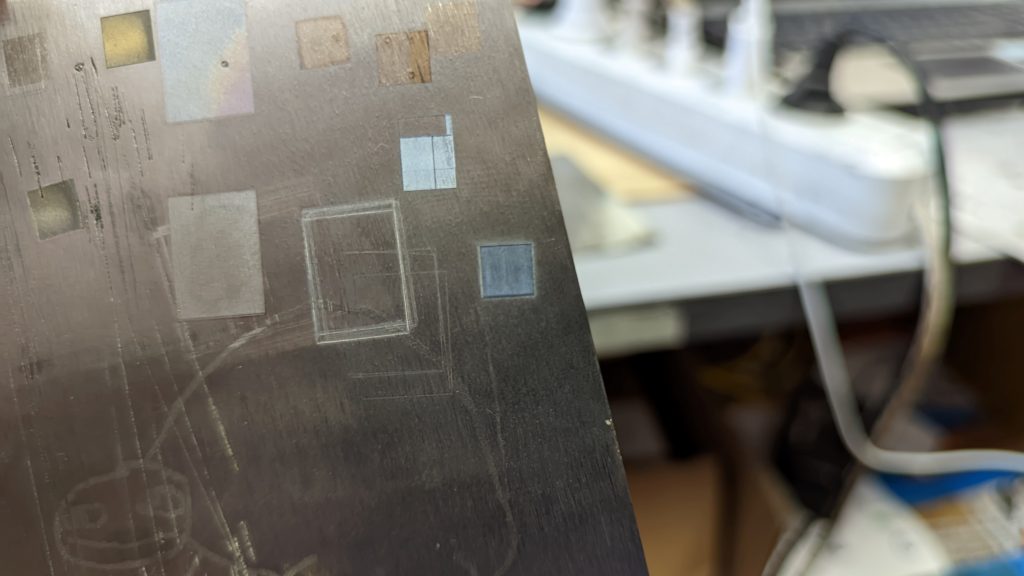

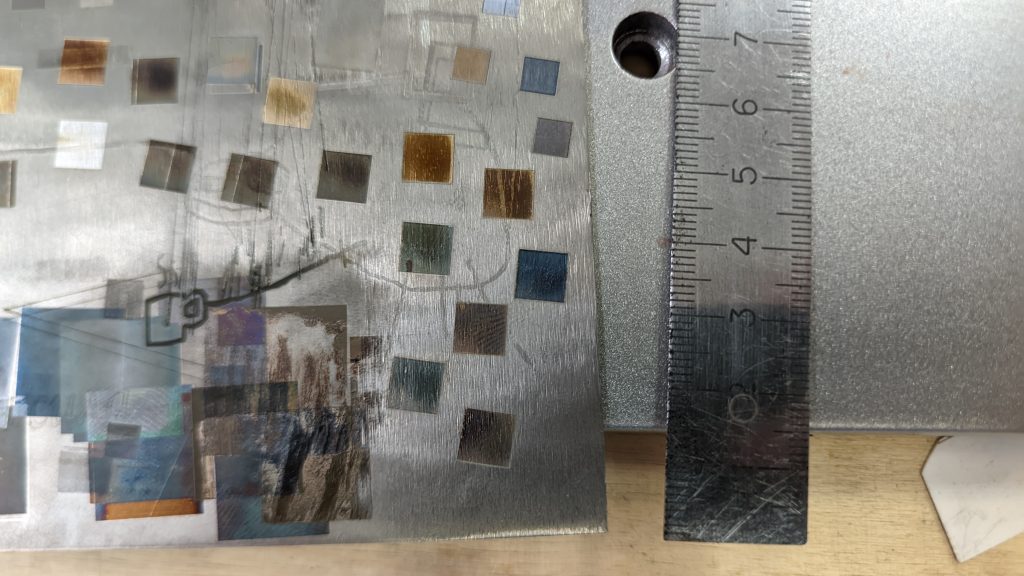

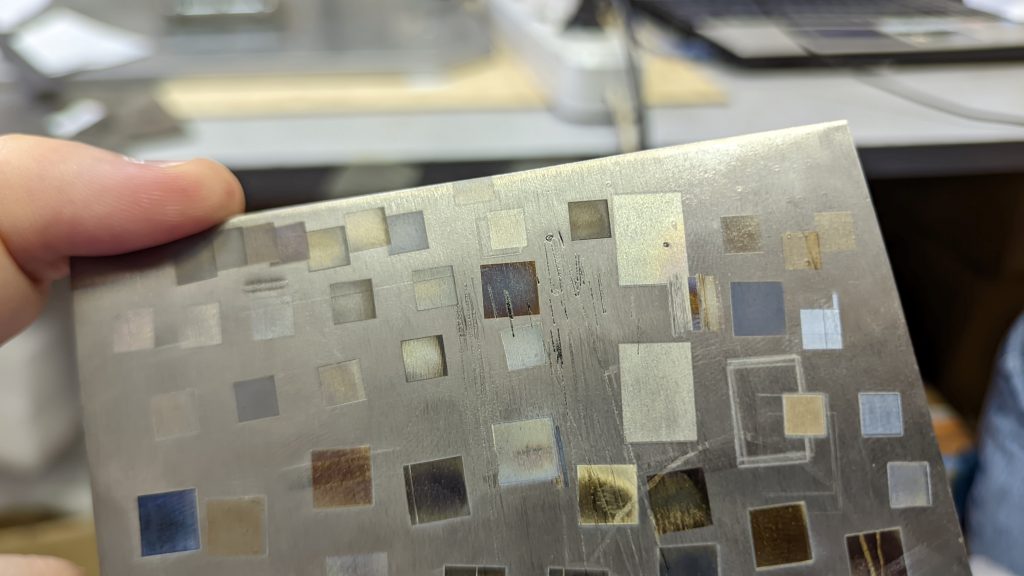

Color laser engraving on titanium with 355 nm DPSS UV Endurance laser machine.

IN our experiment it is necessary to obtain different colors of engraving on titanium.

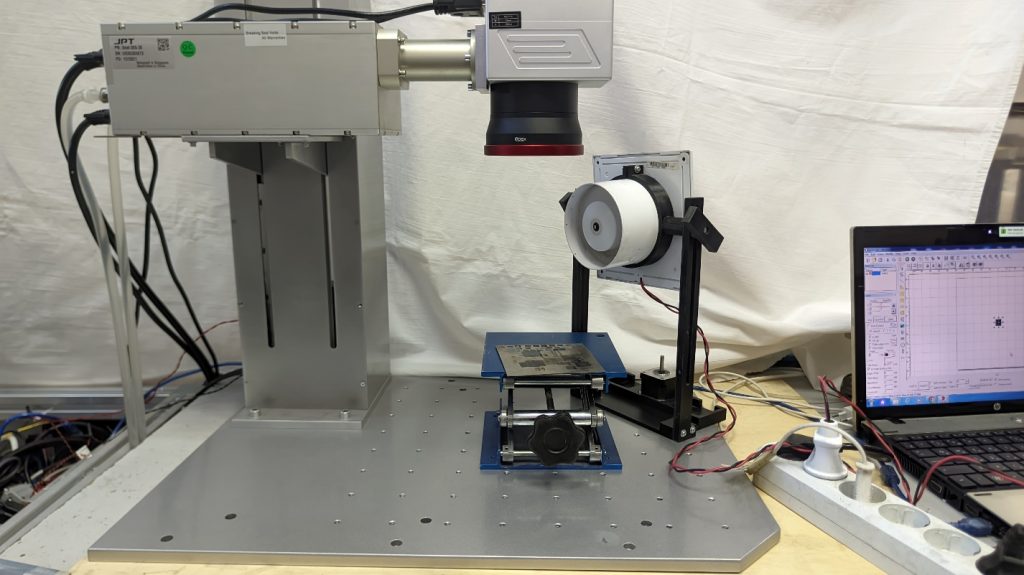

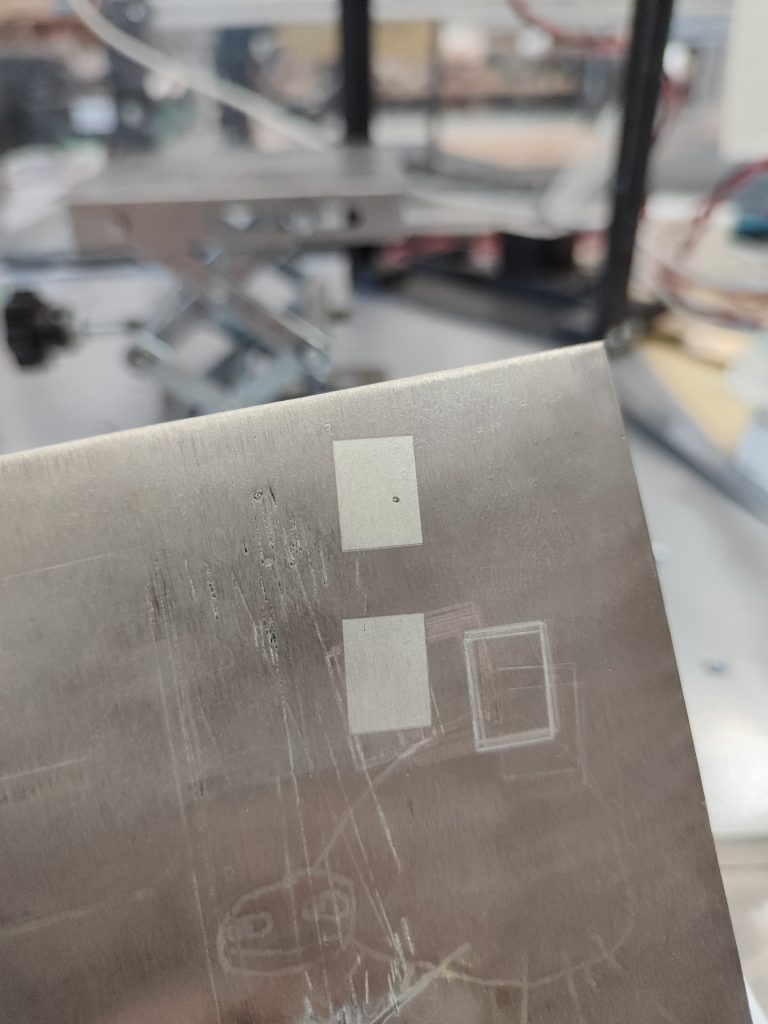

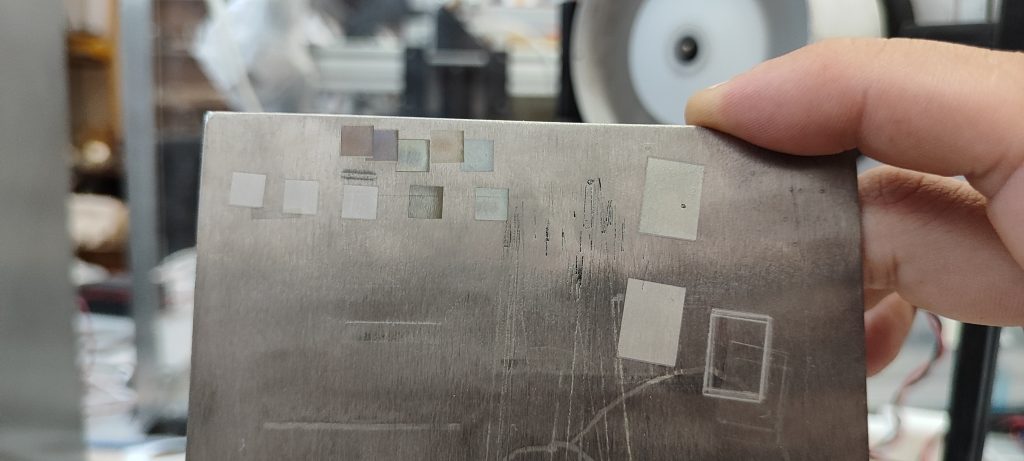

Used Endurance 3W 355nm laser with Galvo installed for engraving An RC 7110 scanner with a lens installed, having a focal length of 160 mm, a wavelength of 355 nm, a working area of 110 mm by 110 mm. The work was carried out on a titanium sheet with a polished surface.

1/3/5/12 watt UV 355 nm DPSS laser modules for engraving, marking and research

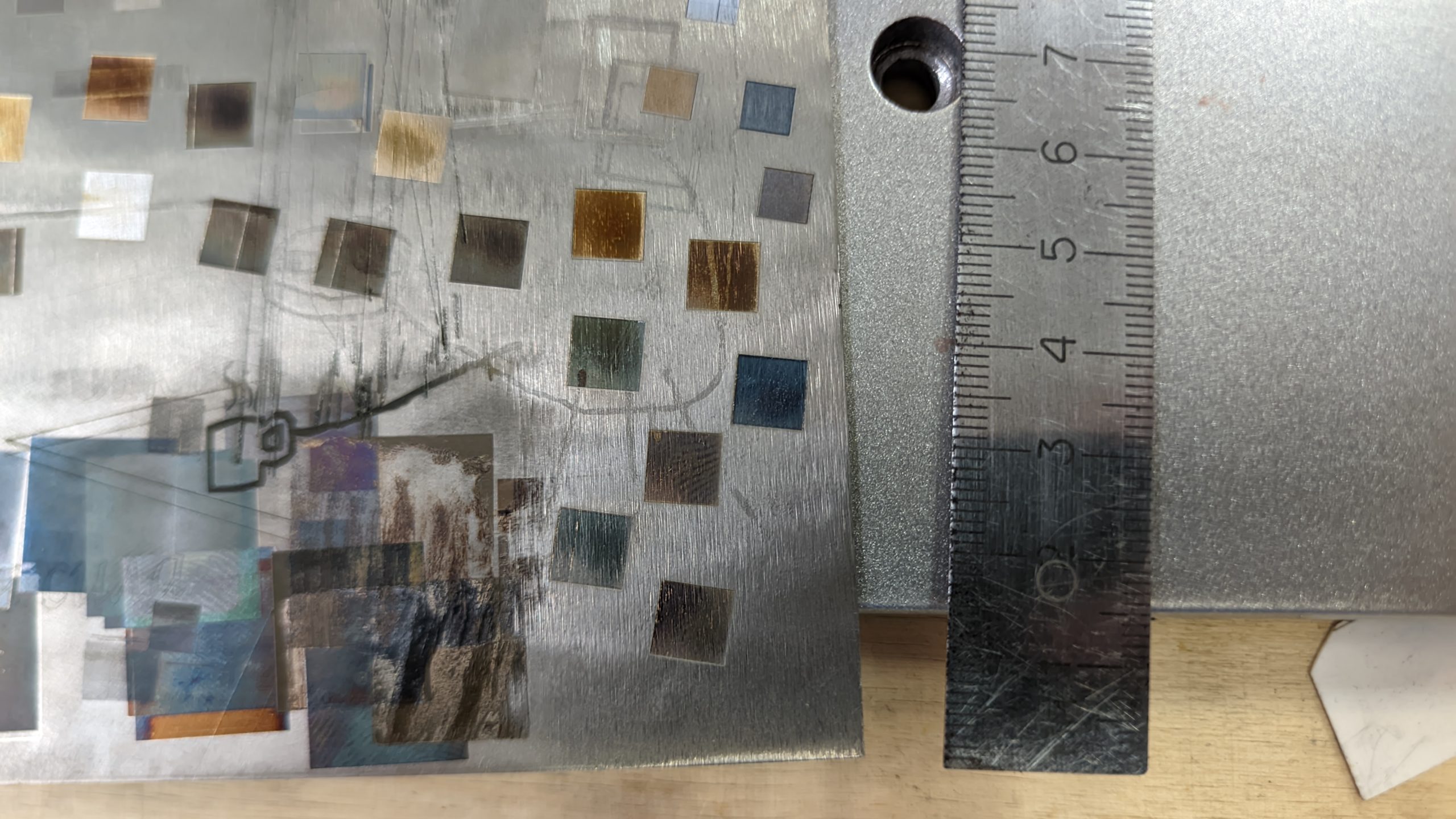

The engraving was carried out in the form of a square 7 mm by 7 mm. The height of the table was 10.5 cm. Color laser engraving is obtained by creating an oxide layer on a metal surface that refracts light.

Endurance 3 watt UV (355 nm) laser module

White color received the number of requests with the number of requests: 1 time, speed 500mm/s, frequency 20KHz, Q Pulse Width 5 μs , space between lines 0.05 mm.

The brown color turned out with a set of parameters: a number of repetitions 1 time, speed 300 mm / s, frequency 35 KHz, Q Pulse Width 5 μs, space between lines 0.01 mm.

Blue color received a number of requests with parameters: 2 times, speed 80 mm/s, frequency 20 KHz, Q Pulse. Width 7 μs , space between lines 0.005 mm.

The purple color turned out with the properties of the parameters: the number of repetitions is 20 times, the speed is 250 mm / s, the frequency is 20 kHz, Q Pulse Width 7 μs, space between lines 0.08 mm.

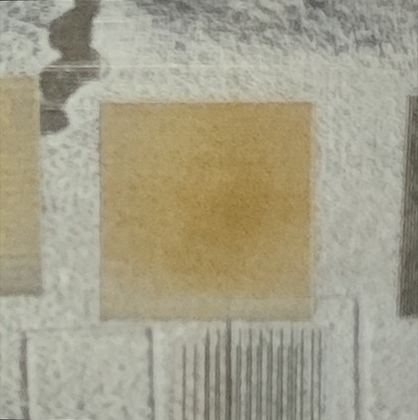

The yellow color turned out with requests: the parameter of the number of repetitions is 1 time, the speed is 75 mm / s, the frequency is 67 KHz, Q Pulse Width 5 μs , space between lines 0.03 mm.

The blue color turned out with the addition of parameters: number of repetitions 3 times, speed 33 mm / s, frequency 33 KHz, Q Pulse Width 5 μs , space between lines 0.01 mm.

The dark blue color turned out with the parameters: number of repetitions 3 times, speed 450 mm / s, frequency 20 KHz, Q Pulse Width 2 μs , space between lines 0.0007 mm.

The brown color turned out with a set of parameters: number of repetitions 3 times, speed 450 mm / s, frequency 20 KHz, Q Pulse Width 2 μs , space between lines 0.0066 mm.

The turquoise color turned out with the following parameters: number of repetitions 3 times, speed 450 mm / s, frequency 20 KHz, Q Pulse Width 2 μs , space between lines 0.0036 mm.

The dark green color turned out with the following parameters: number of repetitions 3 times, speed 450 mm/s, frequency 20 KHz, Q Pulse Width 2 μs , space between lines 0.0025 mm.

The red-blue color turned out with the following parameters: number of times 1, speed 200 mm / s, frequency 70 KHz, Q Pulse Width 4 μs , space between lines 0.0013 mm.

Black color received the number of requests with a set of parameters: 1 time, speed 200 mm/s, frequency 70 kHz, Q Pulse . Width 4 μs , space between lines 0.0007 mm.

The sand color turned out with the addition of parameters: a number of repetitions 1 time, speed 500 mm / s, frequency 35 kHz, Q Pulse Width 7 μs , space between lines 0.007 mm.

The orange color turned out with a set of parameters: number of repetitions 1 time, speed 500 mm / s, frequency 35 kHz, Q Pulse Width 3 μs , space between lines 0.007 mm.

With the Endurance 3 watt, 355 nm laser, you can engrave color engraving on titanium with colors: found, yellow, green, blue, brown, black and their various shades. It is possible to make color pictures on titanium. Color laser engraving is obtained by creating an oxide layer on a metal surface that refracts light. With portrait adjustment, you can change the thickness of the layer, thus changing the color of the picture. The titanium plate can contain different chemicals that can be used for the same settings.

https://endurance-lasers.com/