An air assist is a must addition to the majority of projects involving laser engraving. An air compressor blowing high-pressure air to the engraving area or even a little fan blowing low-pressure air will improve significantly the results of engraving and cutting.

Unfortunately, an airflow, especially of high pressure, can shift a workpiece in the process of lasing and spoil the final result. We can move accidentally the workpiece we are processing.

Here I will tell you how to prevent this happen by means of clamping fixtures.

Types of clamping fixtures

There are two types of clamping fixtures:

- Mechanical

- Chemical

Mechanical clamping fixtures

Weights

Maybe the easiest and cheapest way to hold in place a workpiece we want to engrave is to use a heavy item to pin it down. A heavy hand tool (e.g. a hummer), a big screw or even a heavy screw nut can serve as weights. A really heavy clamping fixture can also keep straight bent thin plywood. The main advantage of this way is that you can easily find a heavy item for free…

The main disadvantage is, as a rule, the size (bulkiness) of the used heavy item, which in some cases can block the movements of the laser module, especially if we use an air assist system that is close to the surface of the processed workpiece.

Magnets

Magnetism is like magic! Just a little magnet can do the business as well as

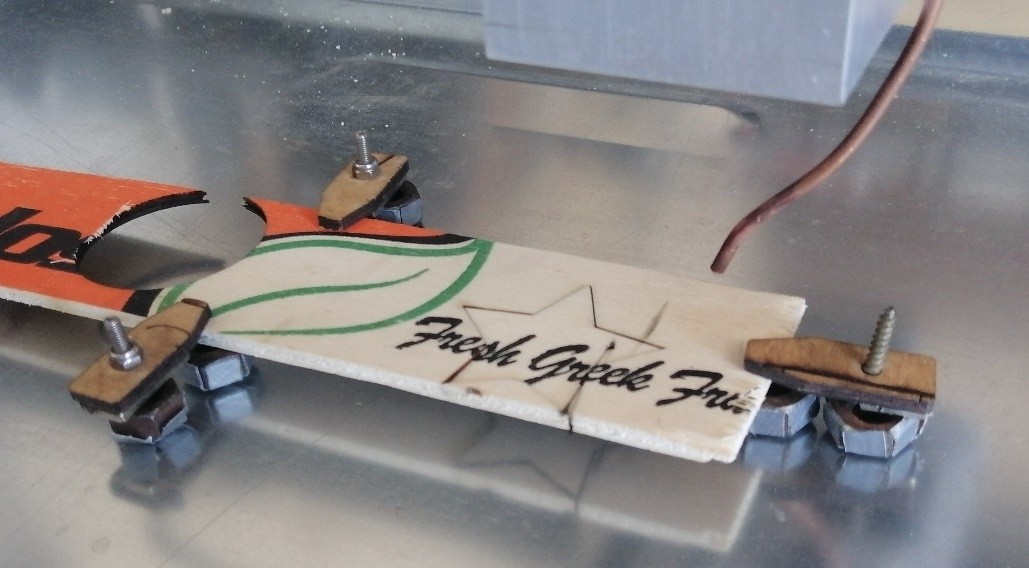

a bulky heavy object. But to use magnets a metallic base is needed. Besides, a metal surface eliminates the risk of fire hazards while the laser is on. For this we can use a thin steel sheet (e.g., steel sides of an old PC case) fixed to the worktable by means of double-sided tape. Don’t use painted metal, especially when you are going to cut something. When burning, paint emits smoke.

We can find two types of magnets suitable for our purpose.

Ferrite magnets

Ferrite magnets are the typical black magnets that we can find in old toys, motors and mechanisms or buy. Due to the black color they do not reflect the laser beam that is good. The disadvantage of this choice is the size. The ferrite magnet must be relatively big in order to have strong enough magnetic field strength to hold a fixed object in place.

Rare earth magnets

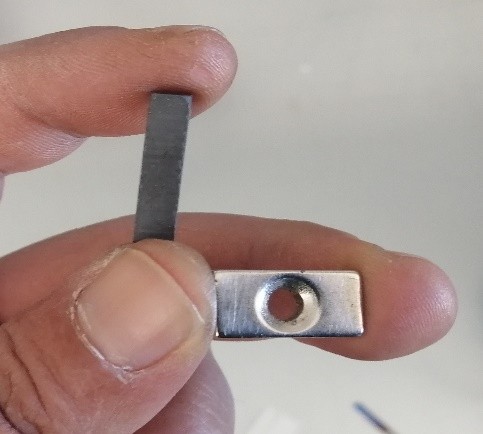

This type of magnet is much stronger than the ferrite magnets but much more expensive. For free we can find them in dead hard disk drives. I believe that the disadvantage of using rare earth magnets is their shiny-nickel color, which can reflect the laser beam and their very strong magnetic power which in combination with their small sizes make it difficult sometimes to detach them from the metal surface.

We can paint them or cover them with plywood or duct tape (as is shown in the picture above), to reduce the possibility of reflection.

A very useful fixture is the combination of a small rare earth magnet with a screw nut. This fixture can work also as a riser.

Chemical clamping fixtures

This type of fixture includes various sticky tapes, hot glue.

I believe that mechanical fixtures are better than chemical ones. Used tapes and hot glue sooner or later go to wastes.

Though sometimes the double-sided tape is the only way out. As we can see in the following video, double-sided tape has been used in order to keep in place little, lightweight wooden ships. In the first instance, we used a layer of masking tape and above it double-sided, in order to peel off it easily at the end.

written by Michail Gedeon