Task: Make barcode markings on different types of cardboard.

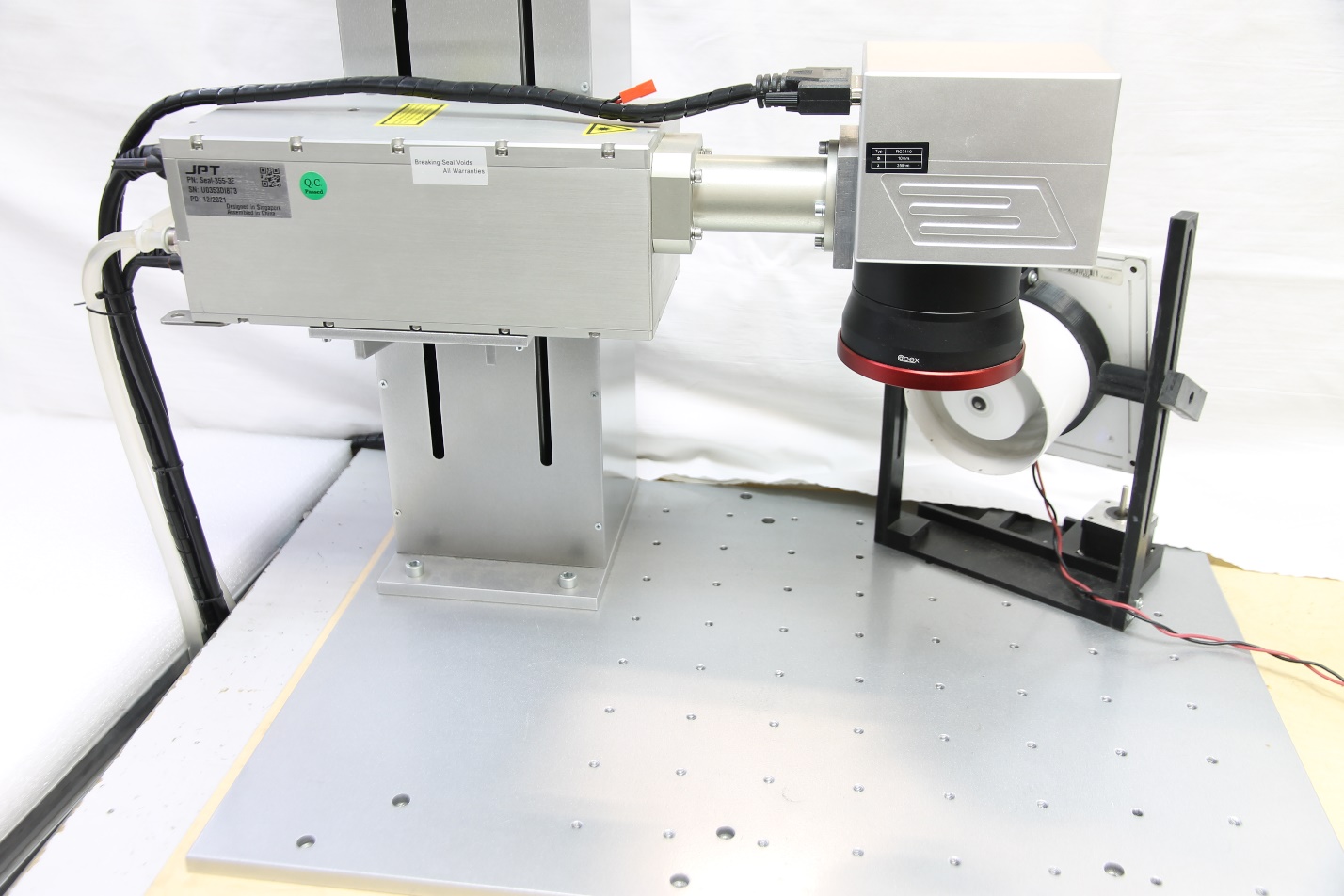

To complete the task, a machine with a JPT seal-355 UV laser with a wavelength of 355 nm , with an average power of 3 W, was used. Pulse duration at 30 kHz is less than 18 ns . The laser operates in the frequency range from 20 kHz to 150 kHz. To maintain the laser operating temperature (25 °C), a water cooling system is used.

Endurance 3 watt UV (355 nm) laser module

The machine is equipped with a galvanometer RC7110 with a lens “SL-355-110-160-D10-LP” installed on it, having a focal length of 160 mm and a working area of 110 mm by 110 mm.

The machine is controlled using the EzCad program .

General view of the installation

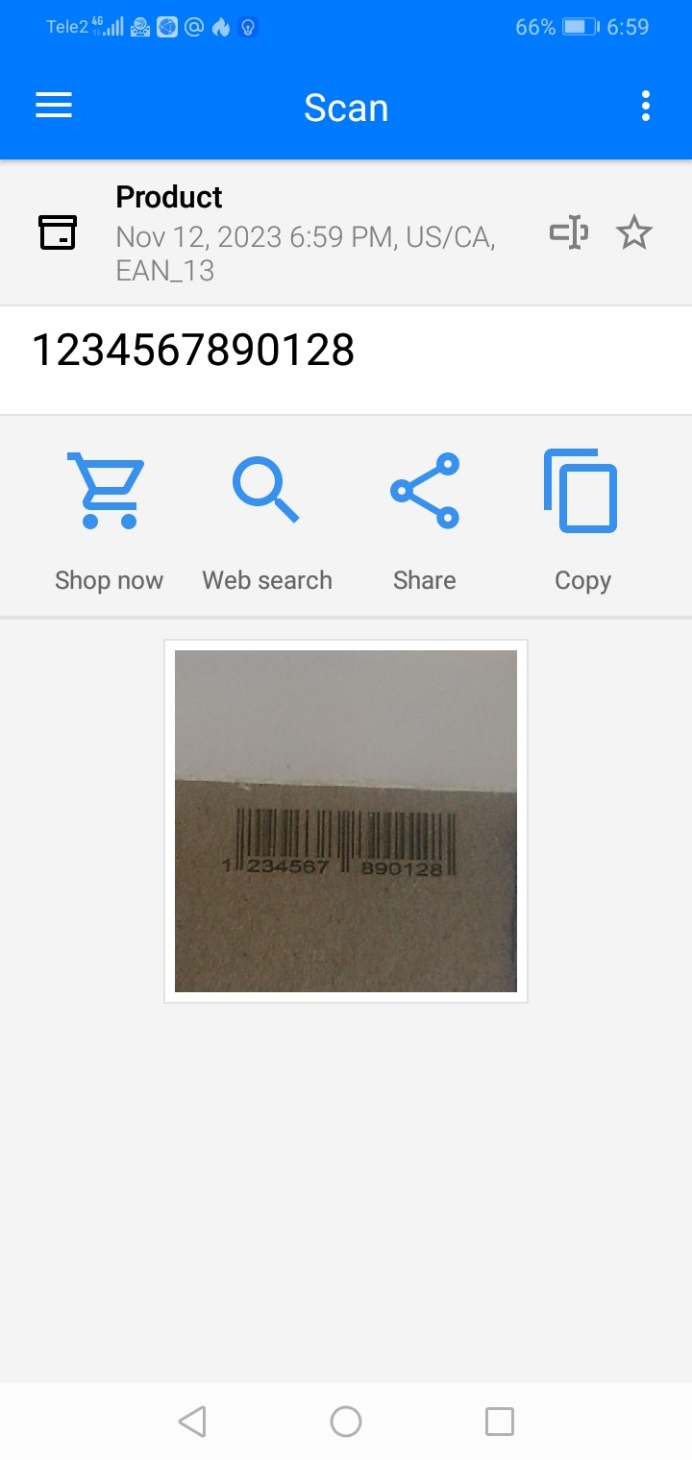

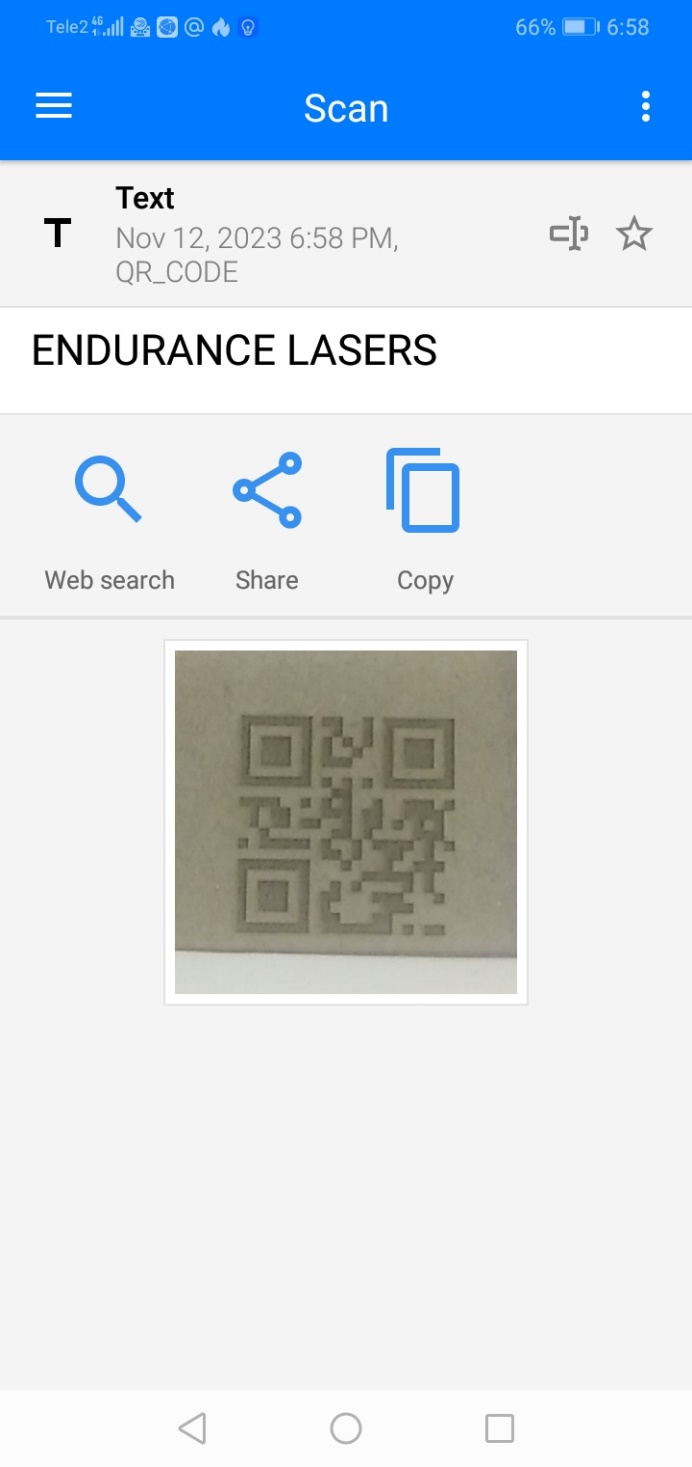

Two types of barcodes were used for marking:

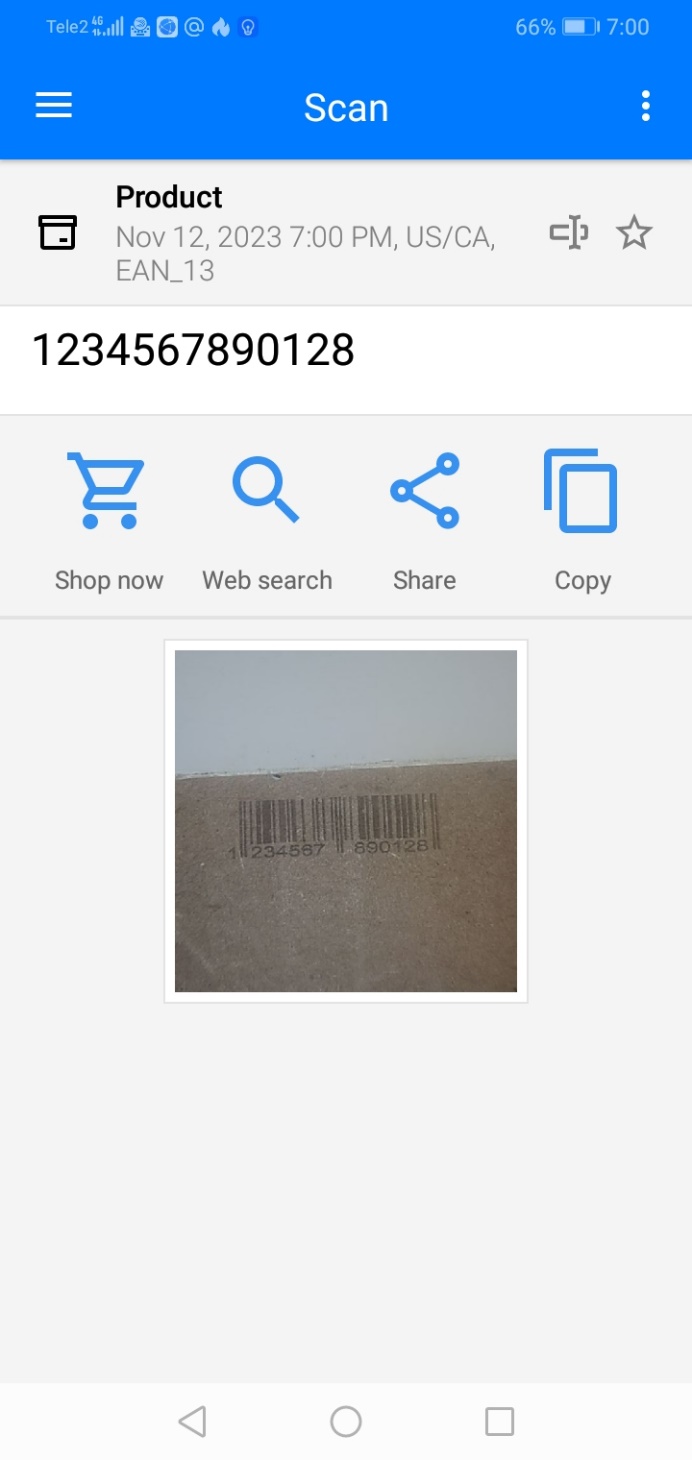

Linear digital barcode in EAN -13 format with the numbers “123456789012” encoded in it. The barcode consists of 13 digits, but only 12 are encoded; The 13th digit – checksum – is automatically inserted by the program.

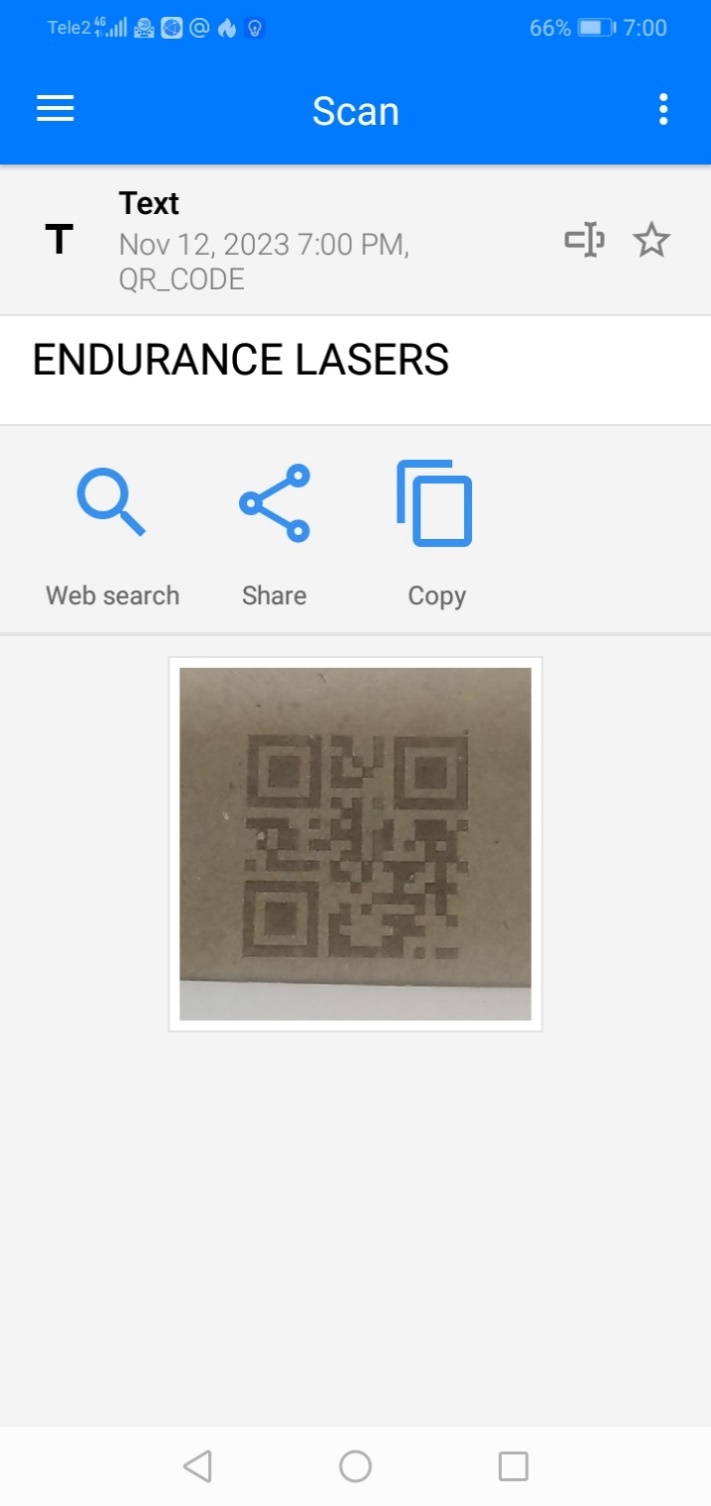

Two-dimensional barcode in QR code format with the inscription “ ENDURANCE” encoded in it LASERS .”

The width of the barcodes was set to 18 mm.

Barcode marking was done by tracing each barcode element along a contour and then filling the contour. The distance between the fill lines was set to 0.05 mm.

Sample #1: Corrugated cardboard

Based on the test results, the following labeling parameters were selected:

Frequency (kHz): 150

Q Pulse Width (us): 2

Speed (mm/s): 200

Loop Count: 2

Start TC (us): 100

Marking on corrugated cardboard

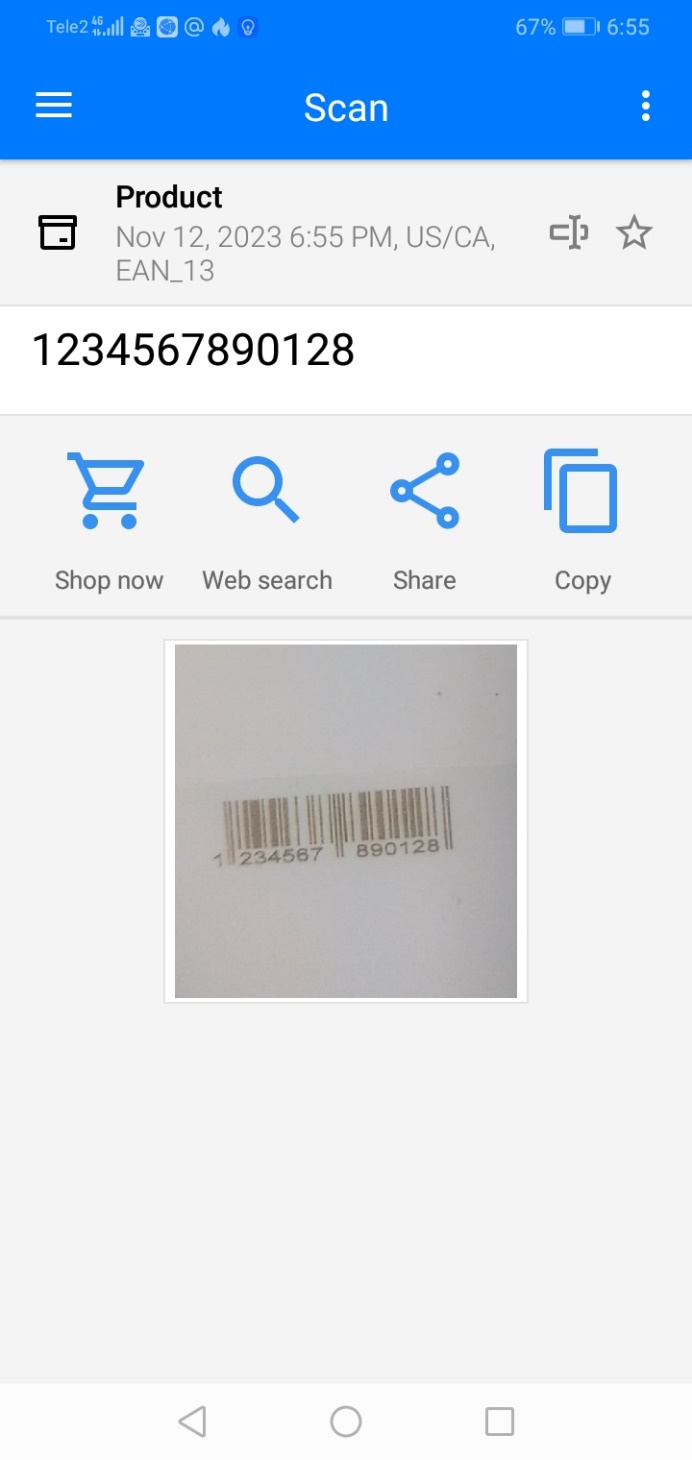

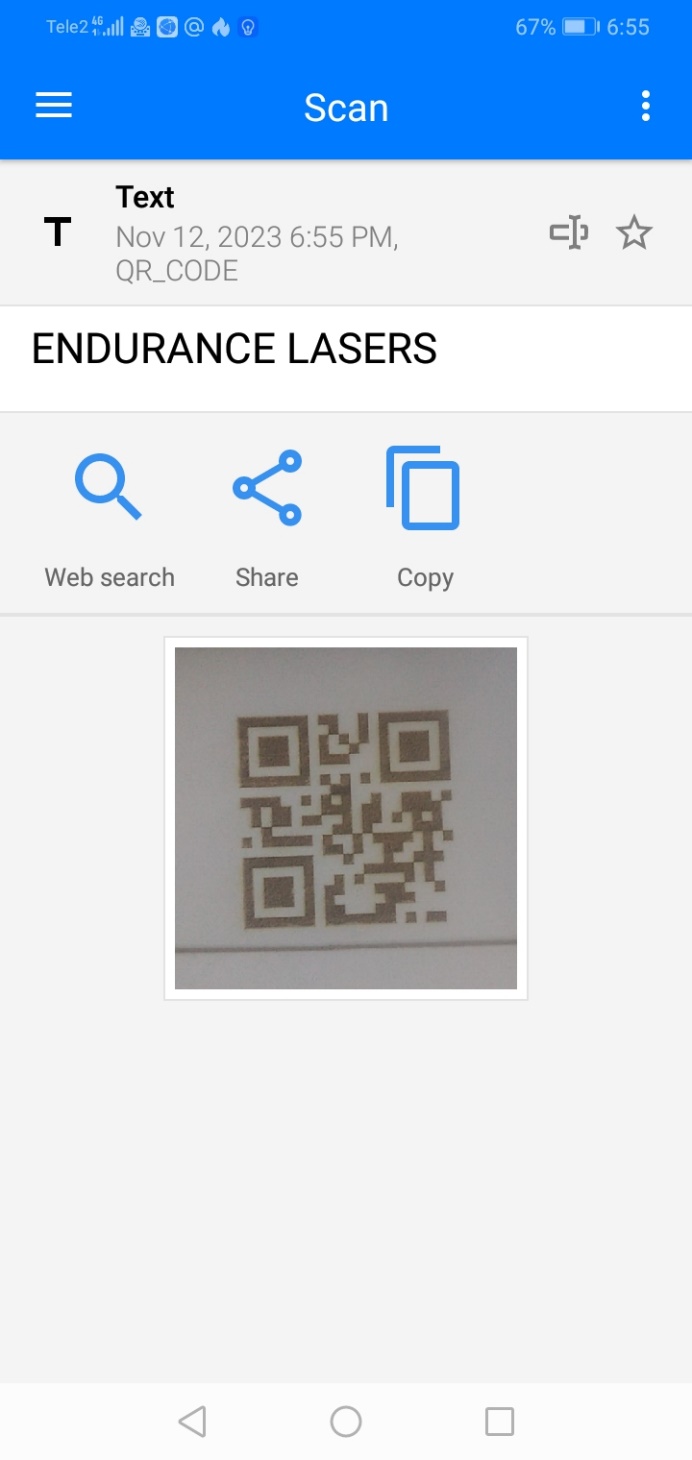

Barcode Reading

| Barcode EAN-13 | QR code |

|  |

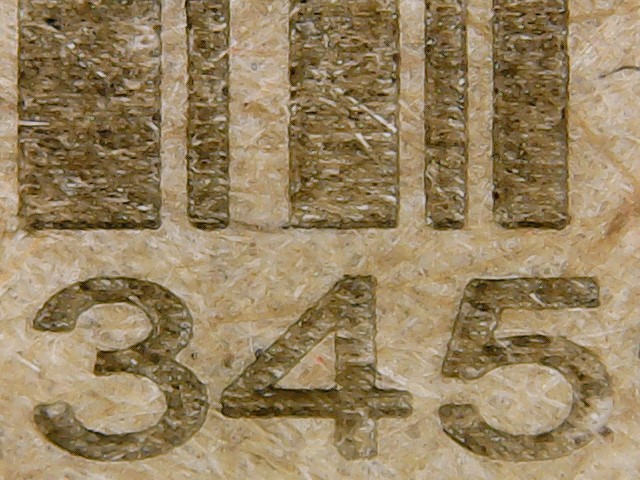

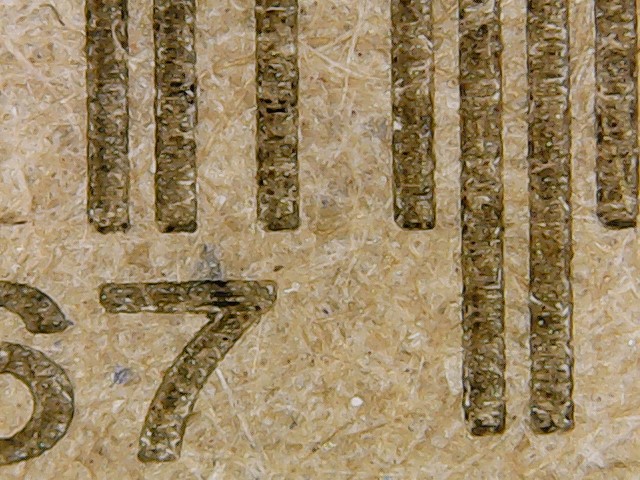

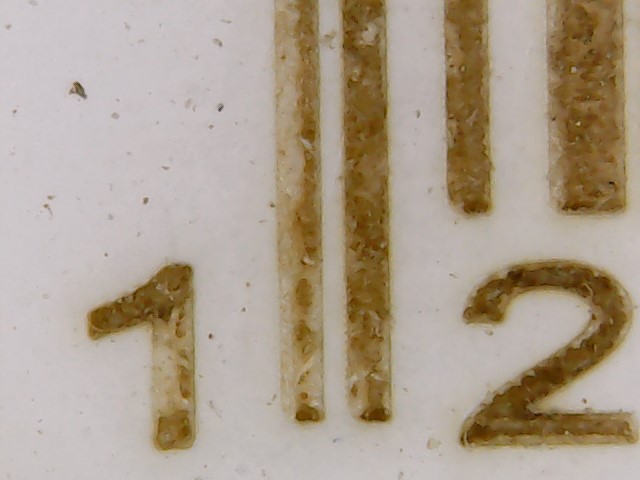

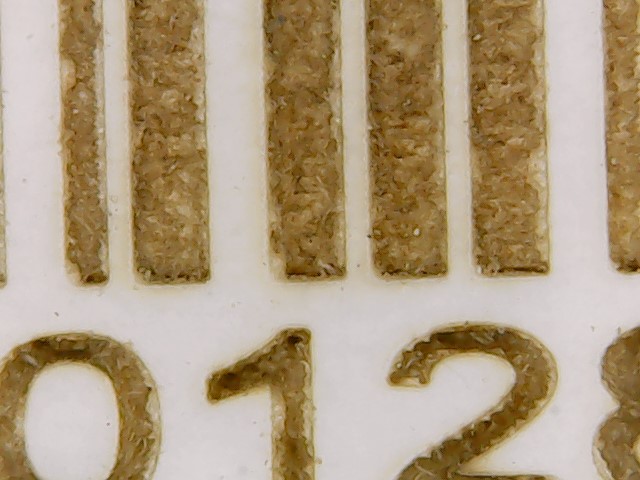

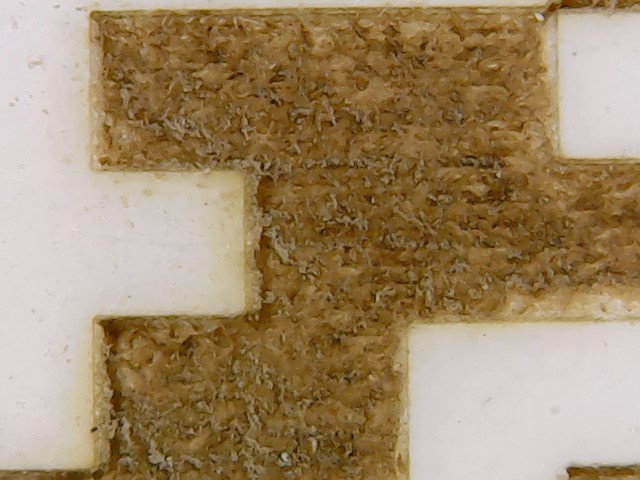

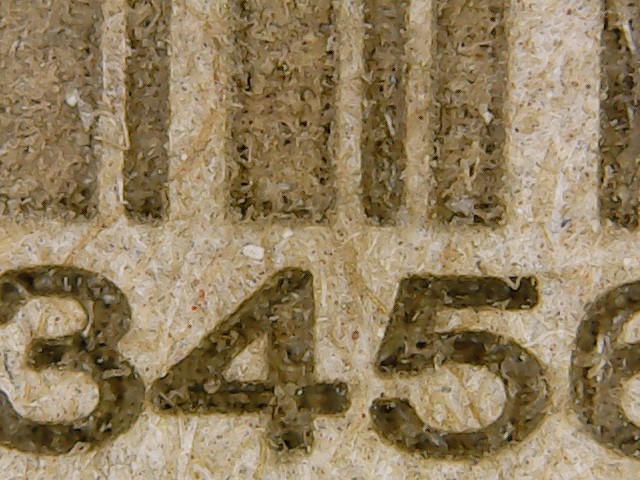

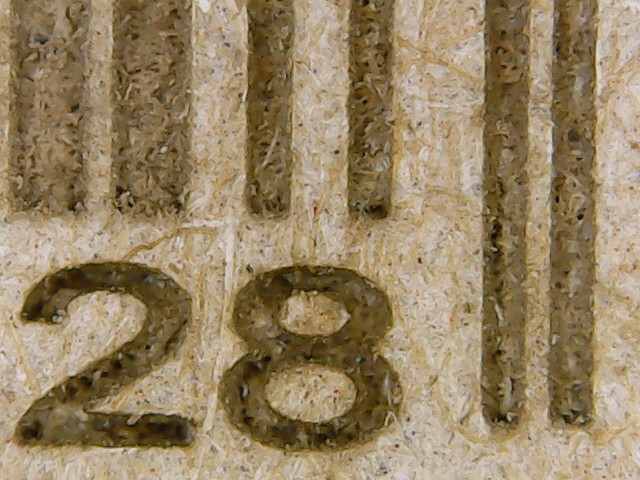

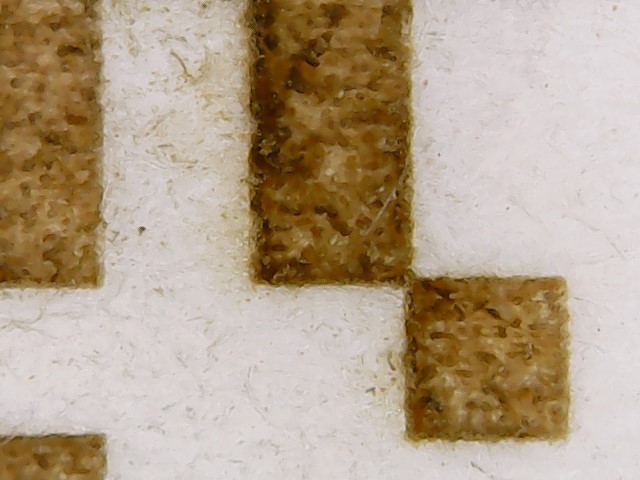

Markings under the microscope camera:

| Barcode EAN-13 | QR code |

|  |

|  |

|  |

|  |

|  |

Sample No. 2 : Coated cardboard

Based on the test results, the following labeling parameters were selected:

Frequency (kHz): 30

Q Pulse Width (us): 1

Speed (mm/s): 280

Loop Count: 3

Start TC (us): 100

Marking on coated cardboard

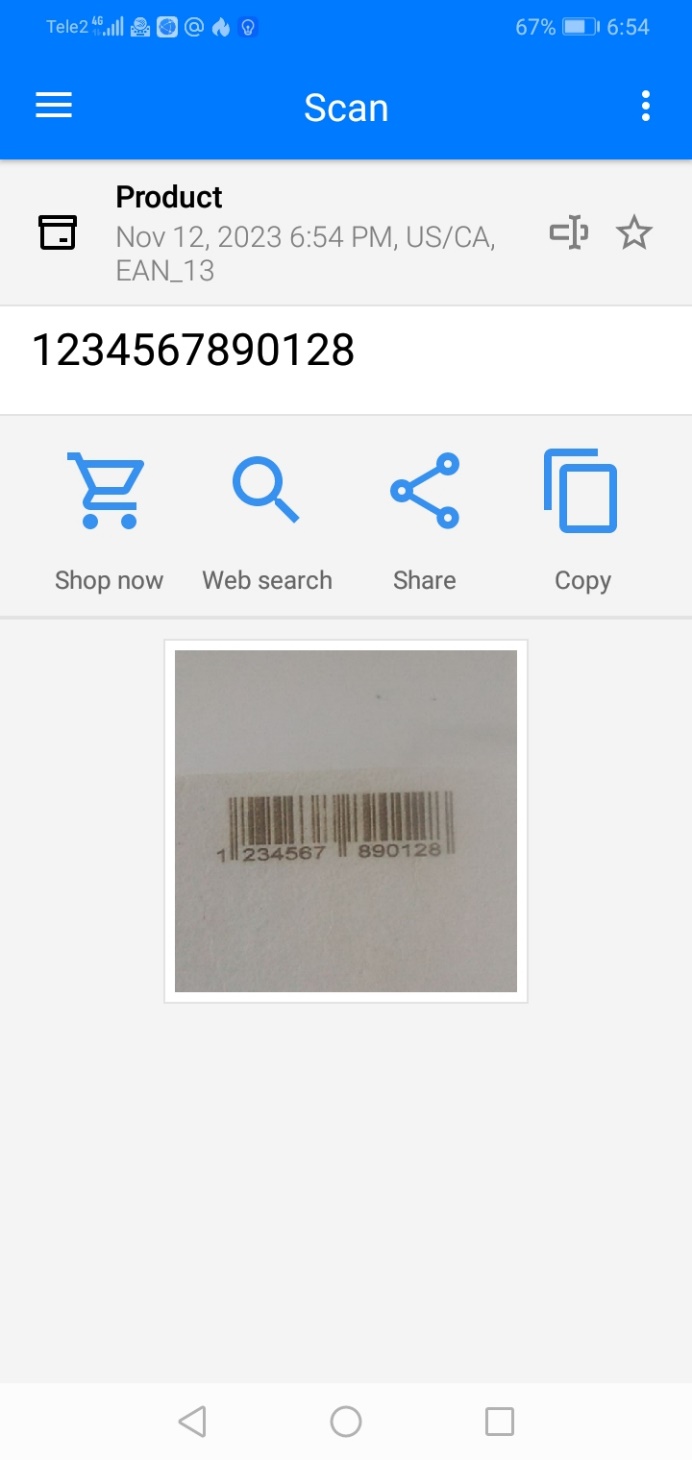

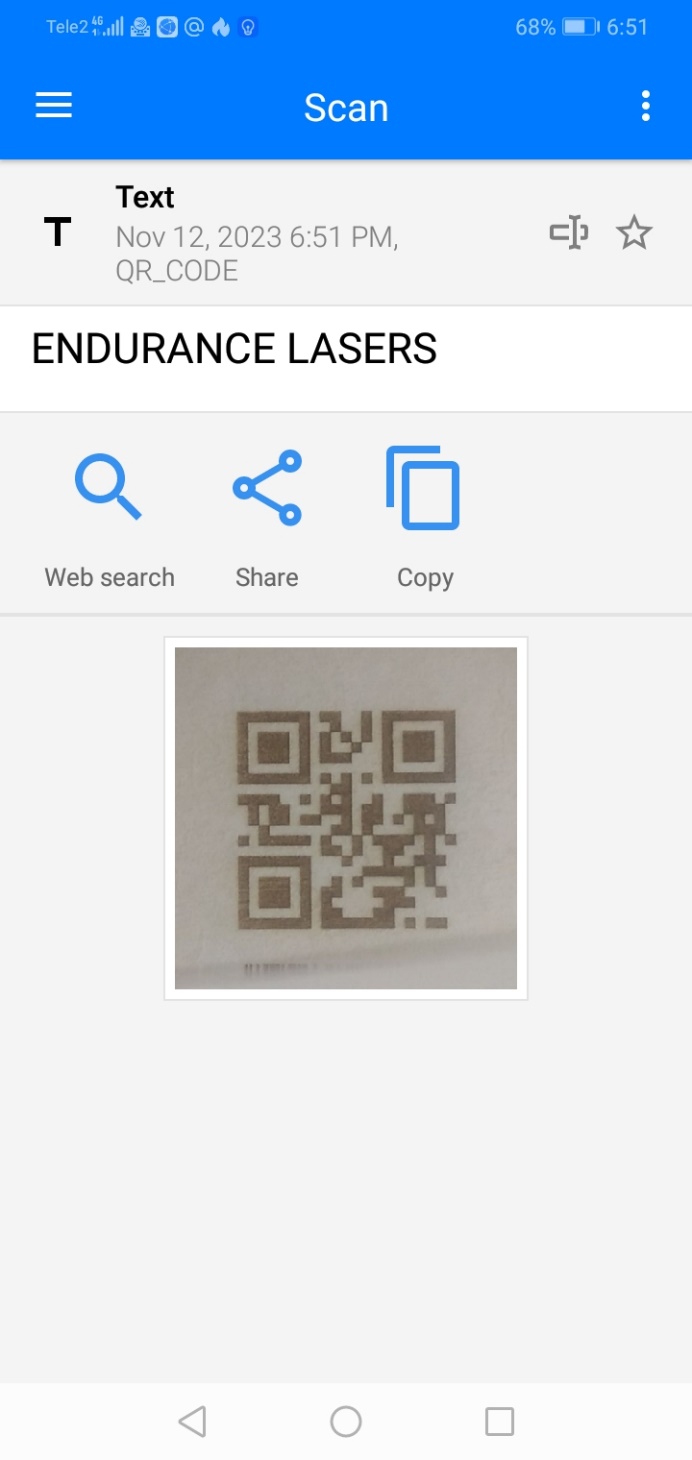

Barcode Reading

| Barcode EAN-13 | QR code |

|  |

Markings under the microscope camera:

| Barcode EAN-13 | QR code |

|  |

|  |

|  |

|  |

|  |

Sample No. 3: Binding cardboard

Based on the test results, the following labeling parameters were selected:

Frequency (kHz): 30

Q Pulse Width (us): 1

Speed (mm/s): 200

Loop Count: 2

Start TC (us): 100

Marking on binding board

Barcode Reading

| Barcode EAN-13 | QR code |

|  |

Markings under the microscope camera:

| Barcode EAN-13 | QR code |

|  |

|  |

|  |

|  |

|  |

Sample No. 4: Beer cardboard

Based on the test results, the following labeling parameters were selected:

Frequency (kHz): 80

Q Pulse Width (us): 1

Speed (mm/s): 200

Loop Count: 2

Start TC (us): 100

Marking on beer cardboard

Barcode Reading

| Barcode EAN-13 | QR code |

|  |

Markings under the microscope camera:

| Barcode EAN-13 | QR code |

|  |

|  |

|  |

|  |

|  |