Leave your testimonial about Endurance lasers

Select your laser

2.1 / 3.5 / 5.6 / 8 / 8.5+ / 10 / 10+

Add your testimonial on our facebook page

All testimonials by Endurance customers

2-2.1 watt diode laser review (feedback)

Nice work.

Nice work.

3-3.5 watt diode laser review (feedback)

The 3.5 is great. Hope

The 3.5 is great. Hope to go even bigger soo

hello everyone, not knowing anything

hello everyone, not knowing anything about laser I found myself in a YouTube movie of the Endurance Laser

I was immediately involved in the clarity of the descriptions and

In the end I chose a 3.5 watts although it is at the hobby level I regretted not taking at least an 8 watts ; anyway to start it’s okay so

it was a great choice: I thank George for his patience and for his help always timely and very useful. Congratulations

Oriano Ghigna

I recently purchased the 3.5W

I recently purchased the 3.5W Laser integrated with the DIY Engraver from Endurance, to replace a slow 200mW Toy from China. After 100+ Engravings, i can say that overall Engraving Time on Wood improved up to 10 Times, compared to my old Laser. Quality of the Engravings is very good, assuming proper focusing of the Laser Beam. I did not try to engrave Stone yet, but i am pretty sure it will work, but i plan to buy a more powerful Module/Engraver from Endurance later on, for advanced Purposes.

My 3.5W Endurance laser arrived

My 3.5W Endurance laser arrived yesterday. Just like plug and play. George was very patient and professional with all my inquiries. I’m a newbie in this area and with the videos and George’s help it almost looked like I knew what I was doing. I’ll be back when I’m ready for a 10W!

Thanks George!

The price performance ratio of

The price performance ratio of the laser is very good. I had a bit of a difficulty to get is started, because the documentation is a bit shallow, but George replied very fast to all questions and even created a small tutorial video for the first setup.

I highly recommend Georges’s products and his support.

Endurance 3.5 Watt Laser

Endurance 3.5 Watt Laser

This is a 5 Star Laser Diode, its very easy to install on any machine having tried it both on my Prusa A8 3D printer and my MPCNC homebuilt CNC machine.

My current project was using the Laser Diode to cut 3mm – 3.4mm Plywood, this laser has no issues cutting through this material in several passes.

If you are looking for a simple laser to setup for cutting wood under 3mm thick this is the laser for you, it also cuts through 1 mm Balsa wood in 1 pass, so this laser would be great for model makers and hobbiest, my current use will be for model ship building.

Also the support and communication from George is very good answering any question I had.

Kane

5-5.6 watt diode laser review (feedback)

After a little time to

After a little time to tame the laser, I managed to get good results in cutting and engraving.

Of course, we must not forget the precious help of George, who spares no effort and his availability.

You want a quality laser, you have to deal with Endurance Laser.

I purchased a 5.6 Laser

I purchased a 5.6 Laser from Endurance not knowing what I was letting myself in for.

I spoke with George many times and he reassured me that it would meet my application needs, anyway 7 days later it turned up from Russia ( very quick I thought) inside was a nice new laser and mo board which I knew nothing about any way after a few connection problems and fantastic help from George and the Endurance Facebook page I was up and running but I was not 100% happy as the Lens would not focus properly Guess what MSG to George 5 days later not one but two replacement lenses and Boom the Laser is so hot on the money and so precise that I am doing things with it that I never thought possible.

If you are thinking of getting a first laser or a replacement I would 100% recommend Endurance.

Marks out of 10

Product 10

Ease of use 10

Support 10

Everything else 10

Many thanks to George and Endurance

Gerald Gunter 1 happy customer.

The laser I got from

The laser I got from Endurance laser was everything I expected, and more. Pre-purchase support was awesome – I don’t think they sleep, as every question I asked was answered with amazing promptness.

I was able to find what I needed on their support web site to integrate the laser into my CNC machine – it really was quite straightforward.

I can easily recommend Endurance laser.

fantastic lazer excellent after sales

fantastic lazer excellent after sales service

7/8 watt diode laser review (feedback)

I’ve bought this laser in

I’ve bought this laser in addition to my CNC machine, in order to cut wood without having the noise of a rotating spindle, and to have more precision as mill bits are fragile under 1 mm. The 8 Watt laser does exactly what I want and is easy to install next to the existing spindle. Despite a small technical issue where the TTL wire was broken on the PCB, the laser performs very well.

Good communication, items as described.

Good communication, items as described. Highly recommended. Thank you!

8W laser for DIY SLS

8W laser for DIY SLS (laser sintering) project

I recently built an in house DIY project which was an SLS (laser sintering) 3D printer to fuse gray/black nylon powder, layer by layer to make some strong mechanical products. The 8W laser from Endurance worked out to be an ideal solution for speed and stable power. The high beam power saved us from having to deal with complicated ambient heaters to make the project a success. George provided excellent support to get it to work. Thanks.

Hey Guys,A quick review for

Hey Guys,

A quick review for on on my time with the 8W laser. I’ve been using it on an MPCNC with a Rambo control board. So far its has worked really well, I’ve mainly used it for picture engraving. the dot burn size I’ve been achieving in MDF and pine has been <0.1 and images at 256 pixel resolution come out with really surprising quality. My main use for this laser was intended to be for cutting ply up to 5mm and acrylic. I've just finished the air assist for it and intend to start on some of the cutting projects soon. The laser has been very stable on jobs that have been at times a few hours in burn time. George has been very helpful in answering questions that have come up. I'd recommend this laser if you are considering it.

Enjoy,

Mike

If you are looking for

If you are looking for a powerful and affordable laser look no more!

I did my research for a while and I couldn’t find a better deal. I had my laser for over a year and it works just as advertised.

For any newbies the laser works great with EleksMaker boards, DXF’s from inkscape and I use T2 laser for the gcode.

The Endurance 8W Laser attachment

The Endurance 8W Laser attachment is a great addition for your CNC engraving machine. It will outperform your expectations due to it’s high quality engineering and manufacturing. George is very knowledgeable and will help you in any way possible with the setup and operation with any of his excellent product line. Your creativity is endless when you add laser engraving to your repertoire.

Since a couple of month

Since a couple of month I do use the 8W laser (Endurance) and I am satisfied with this product. It engraves any type of wood or other materials and is easy to use for cutting MDF up to 3 or 4 mm. I am using the laser on a Stepcraft CNC machine and made a holder for mounting onto the CNC by 3D printing it myself. I am using the 8Watt laser mostly for cutting wood and cardboard up to 2.5 mm and am happy that I made the decision to buy this machine. Thanks George 😉

I recently decided to experiment

I recently decided to experiment with laser engraving and cut using my 3D printer (a cheaper but valid Anet A8, mounted on P3Steel frame) so the 8W Endurance laser has been my choice.

I met since the beginning several problems to understand how to connect and run it to my Anet due to my ignorance on the matter but Endurance (George) has been very kind & patient.

He also prepared a video tutorial using the Anet main board (see how to connect 8,5 watt Endurance laser to a 3D printer) and He was present during the weekend times supporting me everytime 🙂

TAKE CARE FOLKS, this laser is extremely powerful and according to my measurements, it is nearly 9W.

I’ve purchased also the MO1 driver pcb (necessary for my equipment configuration) and the G2 lens.

Next steps are to learn about Endurance Laser plugin for InkScape and of course, experiment with engraving and cutting on different materials.

I strongly recommend Endurance Lasers!

Cheers, Paolo

8.5 watt+ diode laser review (feedback)

I came to Endurance Lasers

I came to Endurance Lasers after searching for a solution to constantly burning out low quality Chinese Lasers.

Endurance Lasers are more powerful and have a smaller beam profile than the above mentioned Chinese diode units enabling me to achieve greater precision for detailed engravings without the troubles and space requirements that accompany low end Co2 systems in comparable price ranges.

George is responsive to issues and although he is quite literally half way around the Earth from me I have received the items I have ordered in a timely manner.

I do think he could do a little better on packaging and documentation of products but my overall experience has been satisfactory.

Big bonus for computer nerds: he accepts Bitcoin as payment.

I purchased my laser 18

I purchased my laser 18 months ago and a lot of miming and aahing and it was a toss up between the k40 modded with 1000 hours and an Endurance with 10,000 hours and Endurance won, mainly because of the comments that I saw on the facebook page and Georges efforts to communicate with his buyers and group.

This company is a start-up and I put my 1100 including post euros in trust and paid George and within a week my Elesmaker A3 and laser arrived all neatly packaged, in a large box.

I was offered a DIY kit for a hundred euros or so less but I wanted turnkey built and ready to go, everything was included, my only issue was software and it wasn’t until I discovered Lightburn did my problems start to go away. I didn’t even know it would work on my Mac.

I was looking for a turn-key solution and to be fair I got that but I found that I could not deal with the open-source software supplied.

I just did not understand it and therefore I did not use or like it and I blame myself partly for that, I don’t think Endurance had been running that long and I guess to keep costs down open source was given as the software.

I feel there is a lesson to be learned here and that new people who are looking for a turnkey solution and not a bolt-on, need guidance and they should be sold a laser with software that an idiot can use and not open source.

As a matter, of course, Lightburn should either be given as the software of choice or advised as the best option for new users to the hobby so that the user will be able to use it straight out of he box. $40 is bugger all in the scheme of things for a piece of software that works. and keeps the customer satisfied.

Most startups fail for one of two reasons, the main reason is cashflow and the second is customer service, fail on either one of those and you go bust

Endurance is still here nearly two years on from my purchase so they must be doing something right.

Just fix the software George Fomitchev and come up with a manual for what you send out be it a Head, 3d printer or CNC 3018 all with lasers, Make sure that you dont assume, your customers know nothing about what you’re selling so give them everything.

I am still happy with my purchase, its works well, George continues to improve and we have had the odd freebie and I won my first ever competition on Endurance.

The site has grown since I joined by over a thousand members and I was made a moderator some time ago which I like the idea of, it means we all get a say in what is happening and how we go forward.

George has placed a lot of trust in his customers and for that reason I am happy and when the time comes I will buy another laser one day from here.

Neil Scott, Sitges, Spain.

A nice 8.5w laser, pretty

A nice 8.5w laser, pretty straightforward install on GRBL based machine.

Impossible to compare to Chinese laser, not a connsodering difference in laser beam qualità and real Power the lifespan of this laser Is way above “cheap” Chinese laser and I’m working with It even 8-12 h nonstop without trouble and Power oscillation.

With a price about 2x the same “hypothetical Power” Chinese laser, you have a machine that allows you to Plan a work Plan without the risk to found It dead near the deadline.

George and Endurance customer care Is also First class, we are still talking about an “open source” world where not all can Always go well with program and board development, but Endurance lasers offer a good price for value and again, a good support

I had my doubts at

I had my doubts at first – but now that I’ve tested it out: This laser is definitely worth the money.

It beats all the cheap Chinese diode lasers I’ve tried by far. With a little time spend dialing in the settings, I can easily cut 3mm baltic birch plywood at 200mm/min in 4 passes. That’s slow by commercial CO2 laser cutter standards, but fast compared to most other diode modules.

The laser came faster than I expected, packaged securely. The guides on here and their youtube channel made it easy to figure out how to focus the laser properly.

I got excellent customer service from George. The only problem I’ve had with it was one of the fans failing. When I emailed to let them know about it, George immediately offered to send me a new one, and when I told him I had already replaced it myself, he reimbursed me for the fan. So they definitely stand behind their products.

Best settings I’ve found so far for 1/8″/3mm plywood are 180mm/min, 80% power, 4 passes.

I’d like to say, that

I’d like to say, that the endurance support is great. We ran into some technical problems and George helped us. He mailed us up to seven times a day according to provide a result of the problem. So we’d like to thank George for the time he invested in us.

Very pleased with my Endurance

Very pleased with my Endurance 8.5 watt laser purchase…George was very helpful all the way through the process by providing answers, suggestions, and professional help in general…After mounting and setting up the laser, it performs exactly as advertised I’m looking forward to more experimenting with engraving and cutting…thank you George and Endurance Lasers for your product and support.

Great work guys!

It is always a risk when ordering products on-line and even more of a risk when you are ordering from another country. You just never really know if the place you are ordering from is just interested in taking your money and you never really know if the product you will get actually lives up to the sales pitch or if it is just going to be junk and the vendor won’t respond to your calls.

Well I can tell you, that is certainly not the case with Endurance Lasers based on the experience I had in purchasing my 8.5 watt laser. George answers any questions I had before I purchased the unit, which would not be that unusual, but when I ordered it and it arrived damaged, George really showed me his true colours. He responded immediately to my email, promised to have a replacement shipped the next day and paid for the shipping to send the unit back to him. Although he provided a tracking number for the replacement, after a few weeks it had still not arrived. To this day it is still showing in-transit. When I brought this to their attention, George stepped up again and immediately shipped me another from their US office which arrived a week later.

I now have my laser installed and could no be happier. This thing is everything they made it out to be, and more. A quick email to them if I have a question and they respond fast and with very helpful answers. This is my first laser so I’m sure a few of my questions were newbie-like, but their responses never have been.

It is so refreshing to buy from a company that really cares and demonstrates superior customer service skills like these guys do.

Great work guys! And fantastic product!

Sincerely,

One Happy Customer.

I just want to say

I just want to say what a fantastic experience I have had in purchasing my 8,5 watt laser from Endurance, I am an Educator and work for a Film School ,Afilm.es here in spain training students in cinematography and we intend to use the laser for two things one to assist us in making parts for films so that the students can learn and secondly my wife is a special needs teacher and I will be using the laser to make toys for the children some who are 5 and 6 and cant even talk but can play, George the CEO of Endurance has helped immensely in choosing the right laser, I must have asked over 50 questions , we have had chats and video links to discuss what i want to do and he is one of the most helpful people I know.

I cant wait for the laser to arrive so we can get to work. George´s attitude to the way he sells lasers is what made me choose Endurance, I was thinking of a chinese laser of ebay but could not get anyone to answer my questions and buying a laser from a ebay company who sells lasers and then toys and underwear is not the sort of company who i should be buying a dangerous but safe machine from, I will need aftercare and in the future will be looking for a CNC Router which Endurance sells and I know where i will be coming, thanks for all your help George, I am sure we will speak more.

10 watt diode laser review (feedback)

Great product nothing to compare

Great product nothing to compare to the little laser head from china.

Work flawlessly. Proçfessionnal equipement

Great diode laser. The price

Great diode laser. The price seems high, but these lasers are nothing like the cheap Chinese ones. It took a little fiddling to get out setup on my Ortur Laser Master 2, but with help from George I got it working and I couldn’t be happier. Great for engraving! Done people cut thin wood with this laser, I think if you’re looking for cutting, get an O2 laser. If you want to quickly engrave, this is definitely worth the price!

Needed help with air assist

Needed help with air assist and George was fantastic, replied quickly with the info I needed. Thanks George!

Fantastic laser with superb quality

Fantastic laser with superb quality and precision!

The laser’s components are all authentic high quality parts and are held in place by a sturdy casing; this really shines when cutting thin lines or engraving fast.

I bought this laser to aid with rapid prototyping and I have not been let down. This laser is super easy to install on any CNC or Cartesian machine and produces fantastic results.

The laser is quite powerful for a 10watt laser, I was able to cut through a variety of different 1/8 ply with just a couple passes.

The precision of the laser is very impressive and will not let you down. I have been using the laser to remove supports from 3D printed parts and adding features the 3D printer could not produce. I have been getting high quality results with repeatable accuracy.

In short this is a must buy for any home

-brewed engineer!

I purchased two 10 watt

I purchased two 10 watt laser modules, one for a friend that I had built a large machine for and one for myself. I have built the machine for myself also, but am still waiting on a couple of parts to come, so I decided to modify one of my 3D printers to accept the laser so I could do some experiments with the laser and setup various settings and buttons for LaserGRBL software that I intend to use with the laser.

My first results blew me away, I couldn’t believe how powerful this laser is compared to the Chinese laser that is supposed to be more powerful.

I designed a button for doing a cut around an image that I engraved, the button would use the Z axis to adjust the cutting height between passes and then return to the original position after cutting.

The results that I will video at a later date were that I could cut and outline 1mm outside of the image very cleanly. The material I used was 7mm pinewood, 2 passes set at full power and 250mm/min.

The edges of the cut were so clean, looked like they were polished, amazing.

I will spend some more time and record my progress while learning more about these Endurance lasers, and then post videos and reports online in order to help others.

If you are using LaserGRBL and would like to add your own 2 pass outline cut button, here is the code I wrote. By adding another level and a few small changes, you can make a 3 pass button as well.

Installed my 10W Module to

Installed my 10W Module to my Ortur Lasermaster 2 with ease. The extra power really makes this unit much more capable. Could not be happier with my purchase. Very happy with the build quality of the unit.

George has been very helpful with all my enquires in regards to which model I would require for what I plan to use it for.

I recently decided to upgrade

I recently decided to upgrade my Ortur LM2 15wPS to a larger laser unit. Mind you I only upgraded the laser unit itself, still the same frame.

After searching for days I ended up going with the Endurance Deluxe 10w laser unit. So glad I did. Amazingly George at Endurance was actually online the day after Christmas and answered all my questions. Was in constant communication via email as well. Very passionate about his product. The constant communication alone was a top decider for me.

My largest move to a 10w laser was for more power. I cut 3-4mm wood for ornaments and other laser cut items. My prior laser unit although worked fine just was taking way to long thus causing me to babysit jobs constantly. I was glued down to my unit since you do NOT want to leave a laser running unoccupied. The Endurance laser shaved 2/3rds my time and cuts are much cleaner. I do use air assist.

Another great bonus to buying this unit was its power and focus. I engrave white ceramic tiles for coasters as well and the quality of the photo image I’m engraving on them improved 300% if not more. Another win. I belong to laser face book groups and many were floored when I shown them my testing ceramic tile tests. The quality is just that much higher!

Setup was easy on my Ortur Frame and the parts appear to be well made. Love the cooling temp gauge on the laser unit control box. I only run my laser at around 80% or lower and so far I have not gone above 22 degrees Celsius. Win! One reason for Diode Lasers dying prematurely is heat and heavy usage. I think Endurance provides a strong fan on their unit and the temp gauge is a plus to keep an eye on the temperatures.

Would I buy again, yes! 100% Yes. Thanks Endurance!

Excellent laser at a very competitive price point

Excellent laser at a very competitive price point. My results have been perfect and trouble free – a real workhorse that can be depended on.

George of Endurance Lasers is the model of excellent support as he is very passionate about what he is making available to his customers. Its always a plus when you are dealing with the mind behind a product rather than a representative.

Note that working with lasers and CNC machines can be a bit challenging, especially with StepCraft devices (they tend to be closed-source), but George was very helpful in this regard and the hurdles where overcome.

So far everything has been

So far everything has been satisfactory and George has been pretty helpful.

Just amazing service, tons of

Just amazing service, tons of information topped with a high quality product. Simply love this 10watt laser!!

Endurance lasers rock!Quite some time

Endurance lasers rock!

Quite some time ago I purchased one of George’s original 10 W lasers. It was an impulse buy as I really had no particular use for it at the time, but I did want to set something up to cut foam sheets for packages. Well, time went by and I never did get around to sending it up. Then the covid 19 virus hit. I took some aluminum extrusion, printed some parts off of thingiverse, grabbed a control board and some stepper drivers and a laser cutter was born. One of the first tests was cutting clear sheets of PETG for face shields to be donated to doctors and hospitals in New York at the height of the pandemic. Since it was a blue light laser, I followed the instructions in George’s video, taping masking tape over the path of the laser to allow it to cut the clear material. Once we had everything set up we expanded the laser path to cut two rows of four shields at a time, which took just over an hour and a half. By the time we were done we had cut 500 shields, assembled them to 3-D printed parts and donated them to various hospitals around town. The laser performed flawlessly. It was, quite literally, a lifesaver. I guess now I have no excuse but to start using it for its original purpose, repurposing large cardboard boxes and cutting foam sheets to properly package refurbished 3-D printers.

George went above and beyond

George went above and beyond helping me with a myriad of issues that are faced by new laser customers. Now I’m hip hopping and bopping to some of the better beats of the tops of the pops! So to speak. He’s always courteous, professional, and prompt.

Brilliant machine would love to

Brilliant machine would love to own one

English below.J’ai acheté ce laser

English below.

J’ai acheté ce laser il y a 1 mois, et il fonctionne vraiment bien, rien à voir avec les modèles chinois.

Les 10w sont vraiment là. Je l’utilise pour graver sur de l’aluminium anodisé des boîtiers d’ampli, et sur mes pédales d’effets. Je peux maintenant graver avec plus de vitesse et gagner un temps considérable.

Quand vous achetez un endurance laser, vous achetez aussi les service de George, qui connais tous ce qu’il y a savoir sur la technologie des laser, mais aussi des machines et du software pour pouvoir travailler correctement.

I bought this laser and it’s work very well. Incredible power, i use it to engrave on anodized aluminium for 1u or 2u rack for amplifier, and to build my design on my pedal. Now i can work with more speed and savent à lot of time for my production.

The bonus when you buy an endurance laser is Georges, this guy are really help full. You can ask any question about laser, about software, about machine, he knows all the things you need to make your job good.

So pleases to receive my

So pleases to receive my new 10 watt Endurace Laser this morning all the way “from Russia with Love” to Spain, Barcelona

I have had the Turnkey 8.5 + watt Laser and A3 LaseAxe CNC machine from Endurance for the last 18 Months but this time around I wanted just that little bit more power. A complete ready to go kit out of the box, Just add Lightburn software, flash the nano and its ready to work on my MAC.

My wife is a special educational needs teacher for an international school here in Spain and she is always asking me to make things for the 4 year olds in her class, The 8.5 watt is good but the 10 watt + is a different machine altogether and it will enable me to take my engraving and cutting to another level for my wife.

We are hoping to make all sorts of games, jigsaws, personalised gifts for the children, just a lollipop stick with their name and class mascot on brings miles of smiles to their little faces, personalised pencils, coat hooks. cups, “Tic Tac Toe’s” you name it I do it.

Now with this Laser I can cut out all sorts of plastics and engrave on non ferrous metals with a special paste, do animal tags, engrave on Brass and Copper which is what I have been wanting to do and add a special whizz to the items I make for the children.

I am lucky to have retired early in life and this is how I spend my time helping my wife at work, It brings an immense pleasure to me when my wife tells me what the kids are doing with their toys.

This machine is worth every penny.

Thanks George and the guys at Endurance who make it happen.

Just email them and stop worrying they will look after you and theres no problems at all, If I have an query I go on to the large Facebook Groups where there are thousands of members waiting to help and come up with all sorts of ideas to make your laser go further and without spending more than a few dollars or euros.

One very happy and satisfied customer from Sitges, Barcelona Spain

Neil Scott ACII

Sitges September 2019.

Mounted on my Workbee 1010

Mounted on my Workbee 1010 (Openbuilds), just perfect!!!

Thanks for an extremely fast

Thanks for an extremely fast international delivery. Just three days from the order. As soon as I have built my cnc machine I will send a picture. Probably will be looking for advice before that

George’s reliability is something over

George’s reliability is something over any expectations. His product is well done and studied to work in any conditions; the support is great, with deep communication about any kind of problem and faster as you can imagine.

When you buy an Endurance Laser you gain not only the product, but George’s confidence too.

George and his company Endurance

George and his company Endurance Lasers is the ONLY choice when it comes to your laser diode project. He has pioneered some of the best products out there and offers the best bang for the buck. He is extremely helpful as well. Once my 10 Watt project is finalized I will be sharing the great results.

Thanks George, keep up the great work!

I had a 0,5W laser

I had a 0,5W laser which broke down, so I was looking for a new, stronger laser for my Makeblock XY-plotter 2.0. George really helped me out by answering all my questions very patiently. The laser itself is very very powerfull, allthough we only use it for engraving (not yet for cutting). So I am very happy with the laser, and I was even more confident with the help and assistance I got!

I bought the endurance 10

I bought the endurance 10 watt laser and can’t be more satisfied. The laser works great out of the box and is easy to install. I use a CNC to create burns from photographs – and the laser burns the exact picture. George answers questions promptly and really stands behind his product. This is a five star product.

I had a question setting

I had a question setting up my DIY laser to a Creality CR-10S 3D printer. George answers promptly (I mean really fast) and answers further if you need any help understanding.

I Was really Excited to

I Was really Excited to get the Laser from George.

Now after 3 Weeks of playing around with the laser Im able to say, it is a realy great Laser. Which puched me forward in my production time. It is easy to install and to work with. For everyone who already got a 3D printer it this a really great attachement.

Also the support from George is the best customer support I know. If something doesnt work correct, he takes care of it, tries out different options in his lab and will come back to you with a solution. Very appreciate it.

After 2 weeks of using

After 2 weeks of using this 10W laser module, i would give 5 stars to endurance laser for producing such a magnificent product. their commitment is very satisfying. Well done George!!!

Having owned some cheap Chinese

Having owned some cheap Chinese lasers that never do what they say they will, I was a bit sceptical as to whether this laser would actually do what Endurance claim it would do. But anyway I went ahead and purchased the 10w version.

I had a few teething problems, most likely because I am new at laser cutting etc and although I have spent my entire working life in electronic assembly, I don’t actually understand a great deal about electronics, just the bare minimum!

Anyway these problems have all been sorted out via a very quick to respond and help customer support! Emails are answered within a very short time and they are very keen to problem solve and get you on the road to using your new laser to it’s best potential!

I am the co-owner of a small craft business and I am looking to use the laser to expand our products.

After building my first personal

After building my first personal laser engraver almost a year and a half ago, Endurance Lasers contacted me about a 10 watt upgrade. I couldn’t refuse. Going from a cheap Chinese “2.5 Watt” laser to this true 10 Watt beast that can run continuously was incredible. This laser is so powerful and can do so much more. Check out my video to learn more about Endurance Lasers 10 Watt laser and how I installed it into my machine at BOS Studios. https://youtu.be/_6wY_eanebM

Laser came in mail extremely

Laser came in mail extremely fast and in great condition. Was very easy to setup and looks professional! Definitely happy with my purchase and this product!

I was informed about Endurance

I was informed about Endurance Lasers by another company, T2Laser which produces laser software. I had a great experience with T2Laser so I thought if they were recommending Endurance Lasers, then it would be worthwhile. I had looked at other lasers over the years, but the most powerful were 3.8 W. I wanted something more powerful. As soon as I contacted George at Endurance, he was very informative and helpful. I really focus on customer service with companies when I buy something, so I wanted to see how he responded to questions. He responded quickly and very thoroughly. I liked that he gave me a personal response each time tailored to my needs. I purchased the 10W laser and as I went through the setup, Endurance Lasers answered every question I had and even looked over my electronics to make sure their product would work with it properly. I’m fully functioning with the 10 W laser and even though I had more complex setup than typical, I was functioning within a day of beginning the installation, which took very little time at all (2 hours total time). Thanks! Will be purchasing more in the future!

my 10w lazer is fantastic

my 10w lazer is fantastic still in the testing stage will cut through 3mm ply 3 passes at 20/255 and 5 passes 200/255 with home made air assist well worth the money well done endurance

10 watt (PLUS) + diode laser review (feedback)

I see there is a

I see there is a new dynamic PWM board to control the laser power, especially for the Shark. That should be a great addition, as George and Ilya helped me make a home-built version of that when I bought my Pro 10 plus almost two years ago. It works great for power control. I did change from direct connection to the Shark control box to a plug-in breakout board.

I started with Inkscape, which would produce vectors only, so pretty much just outlines of shapes and letters. In December 2021, I found that Vectric VCarve would work for laser. I use the VCarve Desktop Quick Engrave toolpath For the 10 watt laser focused at 0.5 inches, I have set my laser as a 0.06” end mill, at 31% stepover, feed rate depending on material, with the CNCShark HD4 Laser (inch) (*tap) postprocessor. This works well with either outline or fill and hatch settings. Fill and hatch does a nicer burn than fill and offset. Next Wave Automation offers a program called Raster which very easily transforms photos/JPEG pictures into a laser .tap file for engraving of photos. I use Google Paint 3D to crop photos, and to remove background of unwanted from the photo before engraving

I have used Raster on white spray painted ceramic tiles to engrave a picture of my daughter’s dogs. I also engraved a photo of a friend’s dog onto boards and used the VCarve to locate photo position on the board, and VCarve to add the letter engraving.

I have used the laser for engraving tiles with letters and photos, signs with lettering and lettering/photo combination. I also engraved mirrors, using reverse engraving to remove the reflective material on the mirrror backside. On a mirror with a flower engraved, I placed colored paper over the engraving for the flower color.

Excellent lasers. Added to my

Excellent lasers. Added to my 3d printer and increased my productivity tremendously.

Nice work. Also I received

Nice work. Also I received a free spare part.

Excellent stuff

Excellent stuff

I am new to laser

I am new to laser technology. I am a knife maker and wanted to engrave blades and other metals used as inserts on knife scales. I did a lot of research and fortunately decided on Endurance. I haven’t done much engraving yet with my 10W+, but what I have done proves to me that I made a great decision. I am really delighted with the level of support from George Fomichev, he has been extremely patient with me answering all my very basic questions promptly, courteously, and respectfully. I think Endurance is a great company for the beginner to get involved in laser technology and for the skilled to grow and expand their horizons.

I had a 5W laser

I had a 5W laser that came with my cutter frame. Intrigued by the 10W+ system I made the plunge and I have to say I noticed a vast improvement in both power and control. Any issues were quickly answered by George. Yes you can get ‘high power’ lasers from China at lower cost but add in the control, the air assist and the technical backup from Endurance and I know what I would choose…Endurance Lasers.

Ordered a 10+ Laser on

Ordered a 10+ Laser on July 07, was delivered July 12 2019 in Quebec, Canada.

Really good service from DHL.

Will review the laser once mounted.

Really great service and fast answers from Georges. Thanks!

10W+ Package

I purchased the 10w+ package from Endurance Lasers and I have to say I am very pleased with it. The laser module and control box are well built, and also comes with a pump for air assist, which helps when cutting material. George is very happy to answer any questions you may have and the website is full of information and documents to help. Again, thanks George for a great product that I will be using for a long time to come.

The 10Watt Plus Laser has

The 10Watt Plus Laser has all the items needed to upgrade your Elekmaker A3 or 3D printer. I have both, but chose to upgrade my A3. Awesome power – this thing speeds up any laser project. I have gotten very detailed raster and vector images made with it. The control box is genius as it allows for some much visibility into the operations that you normally would not see with any other LED laser!

Love it!!!!

I had 2 lasers before

I had 2 lasers before from China. One was 150mW and the other 15W.

Both had no long lifetime and the 15W was lower powered than the 10W+ which I have now from Endurance-Laser. This laser from Endurance is so powerful that I have to run it very fast for a “non-cutting” job – or even throttle down the power over the software. It engraved an anodized aluminum plate 400% faster than the 15W laser from China – and the result was even better. The support is very good and I can say to everyone: ” Buy it and you will never be disappointed”

First of all I’d like

First of all, I’d like to start by saying thank you to George from Endurance Lasers, he has been an absolutely massive help and answered any questions I had. Best of all he replies quickly, within minutes usually! Which is insane, I have never had such amazing customer service before.

As for the laser, it is very well built and you can see the work and research that goes into making it. It’s easy to set up and very good at engraving wood materials, dark-colored acrylic and cutting black acrylic.

Endurance customers say about Endurance lasers & our tech support

The well travelled Laser. A real customer story about Endurance 10 watt SE laser >>>

Back in September 2021, Endurance Lasers dispatched a 10watt laser to me in Australia, using the standard Russian postal service.

Had not thought too much about it until late October, when I realized that I had seen/heard nothing regarding delivery.

Sent a quick note to George, and he advised that the Russian tracking number showed the unit arrived in Sydney on the 6th October. As I now had the tracking details, I keep watching it’s progress, but for the next 2 weeks, it did not move.

As our postal system was having issues with Covid19, it was not possible to ring and speak to anyone about it. Best that could be done was to send a request to chase it up via their website. Waited another week, and as nothing was heard, went to the local post office to see if they could find out anything about delivery. To my surprise, within 5 minutes they had located my package. The bad news was it was now sitting in a container, waiting to be sent back to Russia !!!!

Seems the postal service were not happy with the address, so started the process to return the package to the sender. Tried everything to get it removed from the container, but nothing worked.

Found out that the tracking number used on most incoming items is not visible to the receiver on the Aus Post web site. They use another number to deliver the item, UNLESS you pay more for postage and the it is trackable. This explained why the item looked like it was stuck in Sydney for weeks. It made it to within 8 klm of my house before it was “marked return to sender”.

I let George know what had happened and advised it could be months before it made it to Russia, as it was being returned via sea freight.

At around the 3rd week of Jan this year, though I would ask George if he could see if the laser had been returned. He was pleased to advise it had turned up.

As I was not willing to try the standard post again, I sorted things out with George, and he sent it again via DHL.

The unit was dispatched on the 24th Jan, and arrived at my front door on the 2nd Feb.

The box looked like it had been around the world, which it had !!!

I have a small 3018 Chinese laser engraver and intended to adapt the Endurance laser to it. George suggested I use the Creality CR10, as it would give a larger work area. I agreed.

A few days later, I was offered a Chinese 40watt C02 laser, with a blown tube. This I thought would work well with the new laser, as I would not have to make an enclosure for it. As it was not going to be available for a few weeks, I 3D printed a small adapter and mounted the laser on the 3018, just so I could give it a try.

The laser works as I expected, and was pretty simple to connect everything up. Where I needed help, the Endurance website had lots of information available.

So far, I have only cut some paper and engraved a few MDF sheets, giving me a chance to play with the power settings.

The 10watt laser will replace a 2.5watt Chinese unit, which has been replaced twice, as 2 of the heads became faulty. They were replaced under warranty by the Ebay seller, so I count myself lucky they stood by the product. The 3rd unit still works, but I am sure it is showing signs of failing, same as the other 2.

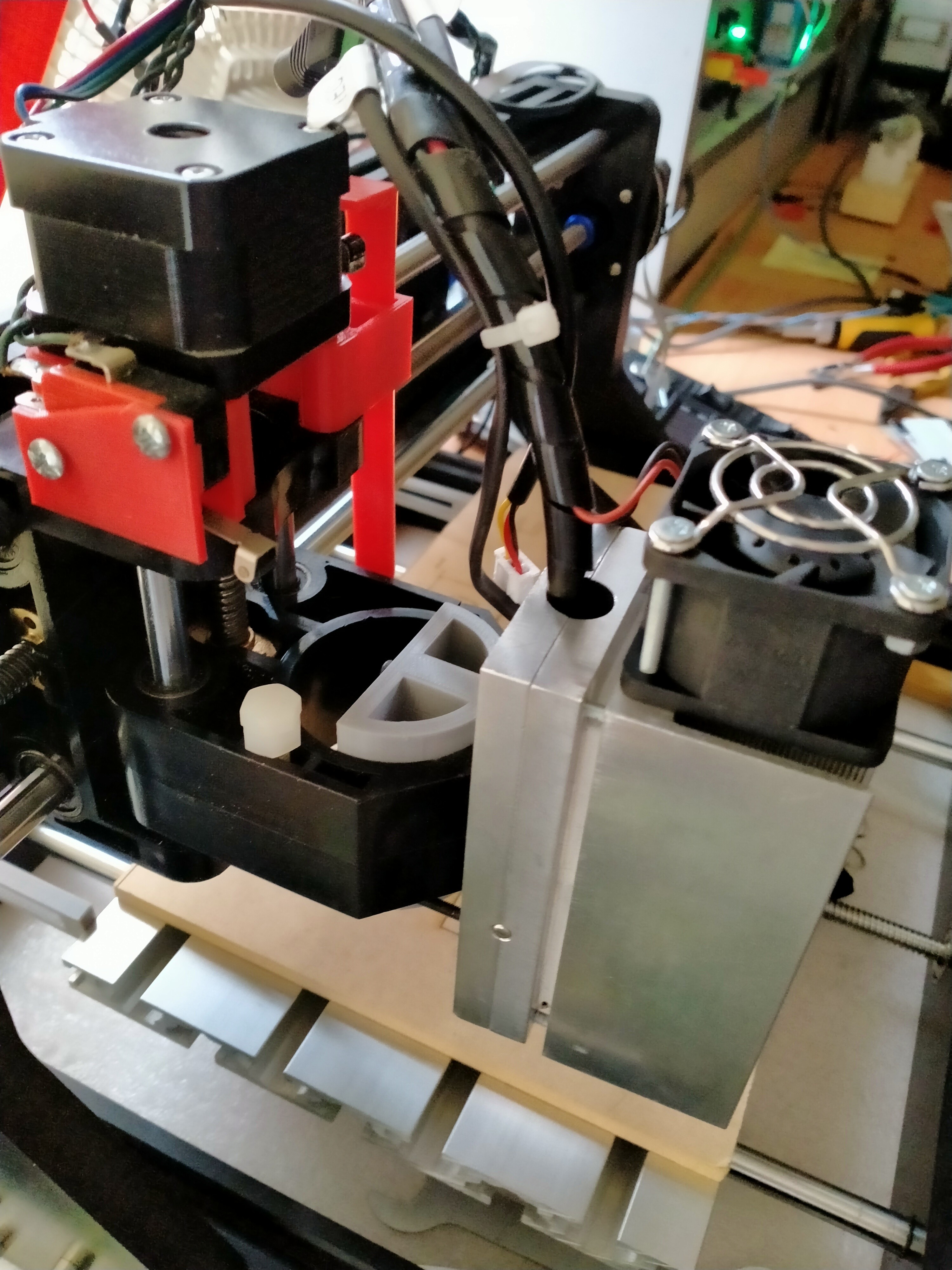

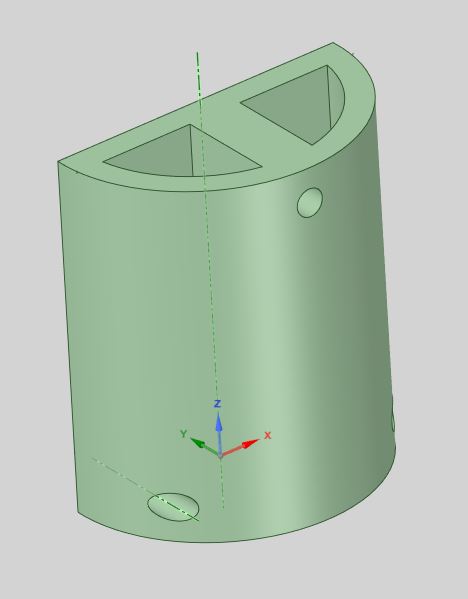

Below is a picture of the adapter I made to mount the unit to the 3018. I used some 35mm long 3mm bolts from the one of the faulty Chinese lasers to mount the adapter. Also there is a picture of the unit ready to go on the 3018. I will move the X axis gantry back by about 35mm, which should enable me to get 180mm of the usable work area with the 10watt laser.

When I get the C02 laser housing, I will see what is required to convert it over to the 10watt Diode laser.