In this post, I would like to tell about the applications of solid-state (diode) lasers.

Here is a list of the most common way of using diode lasers.

- • Laser technologies (welding, cutting, etc.);

- • electronic device technologies;

- • medicine;

- • lidar;

- • atmospheric composition monitoring systems;

- • optical information processing;

- • integrated and fiber optics;

- • laser spectroscopy;

- • laser diagnostics of plasma and controlled thermonuclear fusion;

- • laser chemistry and laser isotope separation;

- • nonlinear optics;

- • ultrahigh speed photography;

- • laser gyro;

- • seismographs and other calibrated physical instruments.

Most commonly used solid-state lasers

Major types of solid-state lasers

| Laser type | Wavelength, um |

| Nd-YAG | 1.06, 0.53, 0.355, 0.266 |

| Nd-glass | 1.06, 0.53, 0.355, 0.266 |

| Er-glass | 1.54 |

| Rubin | 0.63 |

| Ti-sapphire | 0.66 – 0.98 |

| Cr-BeAl2O4 (alexandrite) | 0.72 – 0.78 |

| Commonly used modes of solid-state laser operation | ||

| Laser type | Operation mode | Pulse duration in sec. |

| Nd-YAG | Free-running generation | 10-3 – 10-4 |

| Nd-YAG | Q-modulation (acoustooptical, electrooptical) | 10-7 – 10-8 |

| Nd-YAG | Self-timing | 10-11 – 10-12 |

| Ti-Al2O3 | Synchronization | 10-13 – 10-15 |

| Solid-state laser parameters with a variable wavelength | |||||

| Crystal | Wavelength λ, um | Mode | Average output power, W | Pump source | |

| Continuous | Pulse | ||||

| Ti3+: Al2O3 (Ti-sapphire) | 660 … 986 | + | + | Ar+-laser; second harmonic of neodymium laser 532 nm | |

| Cr3+: BeAl2O4(alexandrite) | 701 … 826 | + | + | Arc lamp/ Pulse lamp | |

| Garnet | |||||

| Cr3+: Cd3Sc2Ga3O12(GSGG) | 742 … 842 | + | + | 0.25 | Kr+-laser, lamp |

| Cr3+: BeAl2O4(alexandrite) | ≈780 | + | 0.09 | Kr+-laser | |

| Fluorides | |||||

| Cr3+: KZnF3 | 785 … 865 | + | 0.085 | Kr+-laser | |

| Co: MgF2 | 1500 … 2300 | + | + | Nd: glass laser | |

| Nd: LaF3 | 172 | + | Laser | ||

| Ce: YLF | 325 | + | |||

| Ce: LaF2 | 286 | + | |||

| Cr3+: Be3Al2(SiO3)6 (emerald) | 729 …809 685 | + | + | 0.32 | Kr+-laser, lamp |

| Cr3+: ZnWO4 | 980 … 1050 | + | Kr+-laser | ||

Solid-State Continuous Wavelength Lasers

Solid-state lasers are able to operate both in a pulsed and in a continuous mode.

Calcium-fluorite CaF2 Dy dysprosium-doped lasers and yttrium-aluminum-garnet lasers with dopes of various rare-earth atoms are examples of solid-state continuous-wave lasers. Most of these lasers operate in the wavelength range λ from 1 to 3 microns. A typical value of the generation power of a solid-state laser in a continuous mode is ~ 1 W or fractions of W, and ~ tens of Watts for an yttrium-aluminum-garnet laser. Without special conditions, the generation spectrum of solid-state lasers is relatively wide, since a multimode generation mode is usually realized. However, by introducing selective elements into the optical resonator, it is possible to obtain a single-mode generation, which is usually associated with some decrease in the generated power. There are certain difficulties in the process of large single crystals growing or cooking of large samples of homogeneous and transparent glass.

Let’s consider as an example an Nd: YVO4 solid-state laser.

The Nd: YVO4 crystal is in high demand for the production of solid-state lasers. The high absorption coefficient, absorption in a wide bandwidth, and the high probability of stimulated emission at the generation wavelength in an Nd: YVO4 -doped crystal are three main advantages of Nd: YVO4 crystals as compared to other materials in the diode-pumped solid-state lasers manufacture.

Manufacturers have been looking for ways to grow high-quality Nd: YVO4 crystals since the 70s. Experts should be aware that grown crystals give higher quality components, despite the fact that the process of crystals growing in large quantities is very complex, not to mention growing of large crystals. Currently, ITI has managed to become a leader in the production of Nd: YVO4 crystals. There are also other materials with such dopes as Er: YVO4 and Yb: YVO4.

Active Substance of Solid-State Lasers

Luminesce (dielectric crystals and glass) solid-state lasers.

Rare-earth ions or ions of the iron (Fe) group are commonly used as activators. Optical and semiconductor lasers are pumped according to a three- or four-level scheme. Modern solid-state lasers are capable of operating in a pulsed, continuous, and quasi-continuous modes.

Various mechanisms are used to create the inverse population of the laser medium. In solid-state lasers, it is carried out by means of irradiation with powerful gas-discharge flash lamps, with focused solar light (the so-called optical pumping) or with other lasers (in particular, semiconductor).

Schemes of Solar Solid-State Laser Generation

For the first time, induced radiation in the optical range was obtained by T. Maimann in 1960 in a solid-state ruby pulsed generator. The creation of the first laser was preceded by the fundamental studies of Soviet (A. M Prokhorov, G. N Basov) and foreign (A. Shavlov, U. Townes, D. Weber) scientists. Another type of solid-state pulsed lasers were four-level neodymium-doped glass oscillators with a radiation wavelength of λ0 = 1.064 μm. This generator was created by E. Snitzer in 1961.

To describe a solid-state laser model, we need to fulfill three basic conditions:

- It is necessary to have a substance with the population inversion ∆N = Nn – Nm, i.e. so that from the two selected levels the upper level was more densely populated than the lower one, where Nn, Nm are the populations of the energy levels En, Em. The population inversion is determined by pumping.

- The active medium must be placed in an optical resonator – a system of two parallel mirrors in order to provide positive feedback. As a result, part of the radiated energy, propagating inside the active medium, is amplified due to the forced emission of photons by new atoms being involved in the radiation process.

- The gain G (ν) given by the active medium must be greater than a certain total threshold value of the losses in the resonator β∑ defined for each solid active substance. Generation will be possible when the self-oscillation condition is satisfied:

In the first system, the optically pumped radiation transfers the quantum particles into a wide absorption band Е3, and then the atoms quickly pass to the metastable level Е2. If the pumping power is sufficient, then population inversion arises between the main Е1 and Е2 level. The stimulated emission is generated from the metastable level Е2. to the main level (or from Е3 to the auxiliary level Е2 in a four-level system).

In a general case, the change in the level populations is caused by three quantum mechanisms: by spontaneous transitions to lower levels; by stimulated emission and absorption; by nonradiative transitions excited by thermal processes and interactions with lattice vibrations.

Comparison of Diode-Pumped Lasers with Competing Technologies

The main advantages of laser diodes over pulsed lamps used as pump sources, overall laser efficiency increase and longer service life.

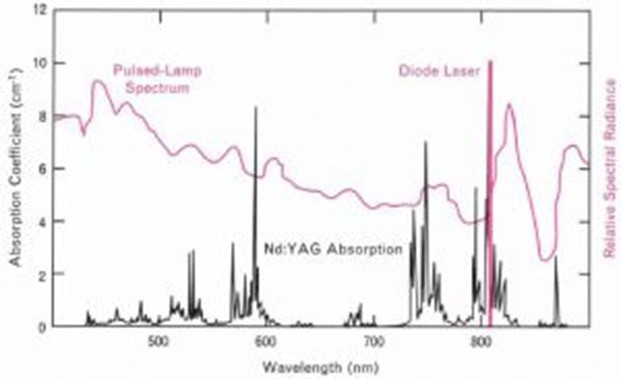

The increase in efficiency is associated with more efficient use of optical radiation pumping. Figure 2 shows the absorption spectrum of the most common solid-state laser material (Nd: YAG), and the output spectrum of a flash lamp and a diode laser, illustrating increased efficiency.

Optical absorption of Nd: YAG exists only in relatively narrow wavelength ranges; thus, most of the energy of the lamp broadband radiation passes through the material without absorption.

Pulsed lamps convert electrical energy into optical energy more efficiently than diode lasers do ( 80% efficiency as compared to 30% – 50% efficiency in tube lasers), but due to the inefficient pump radiation absorption, the efficiency of lamp-pumped Nd lasers is, as a rule, only 1% while the efficiency of diode-pumped lasers is 10%.

This increase in efficiency has more positive effects. The amount of heat removed in Nd: YAG is reduced by three as compared to flash lamps, which reduces cooling requirements and allows using of contact cooling instead of liquid cooling in many cases. When an Nd: YAG is pumped with continuous Kr arc lamps instead of flash lamps, the thermal load is reduced. Heat causes thermal deformation of the amplifying medium, which reduces the laser efficiency; these problems come down to diode pumping.

Lamps and laser diodes have certain lifetime limitations, but the laser diode lifetime is much longer. Lamps are to be replaced every few hundred hours of continuous operation, while laser diodes are able to perform much longer, tens of thousands of hours. In a pulsed mode, the laser diode lifetime is about 10^9 pulses as compared to 10^7 pulses for pulsed lamps. The long lifetime of a laser diode as a pump source has a particular advantage in space-based laser systems since the replacement of a pump source will be expensive.

The main disadvantage of the laser diode as a pump source is purely financial. They are much more expensive than lamps or arc lamps. Today, the lamp needed to excite a 10 watt laser costs several hundred dollars; the cost of the equivalent number of laser diodes is several tens of thousands of dollars. However, according to estimates, the price of laser diodes will drop significantly as their production volume increases, similar to other semiconductor technologies, such as integrated circuits.

Radiation Characteristics Comparison

Solid-state lasers have a number of advantages over diode lasers. Solid-state lasers are able to work in the wavelength range, which is absent in diode lasers or in which diode lasers show bad performance. Additionally, the output radiation intensity of the solid-state laser is much higher, and the radiation is more coherent than in the diode laser. Laser diodes emit separate beams of non-coherent radiation while in solid-state lasers they pump radiation of one coherent beam with a higher output radiation density than in laser diodes.

The solid-state laser can produce a higher peak power than the laser diode as a pump source. The laser diode peak power is limited; output pulses produce only a small increase in peak power. In contrast, the solid-state laser can accumulate the pump powers from the laser diode up to several hundred microseconds. This stored energy can be released in a 10-nsec pulse, using Q-switching, which results in a peak output power 10 ^ 4 times bigger than that of the laser diode.

In addition, the solid-state laser may have a narrower line width than the laser diode. The fundamental limit for the width of the laser line is reduced, and the Q-factor of the laser cavity increases. The materials of which the solid-state laser consists have optical losses less than those in the semiconductor material of the laser diodes and, therefore, may have more Q-factor of the optical resonator.

The disadvantages of using laser diodes for solid-state laser pumping are greater complexity, lower efficiency, and high cost. In practice, their application imposes a number of requirements, such as the required overall efficiency, peak power, wavelength, and radiation intensity; this is what determines the choice.

All you need to know about diode lasers