Task: Make QR code markings on PETG plastic.

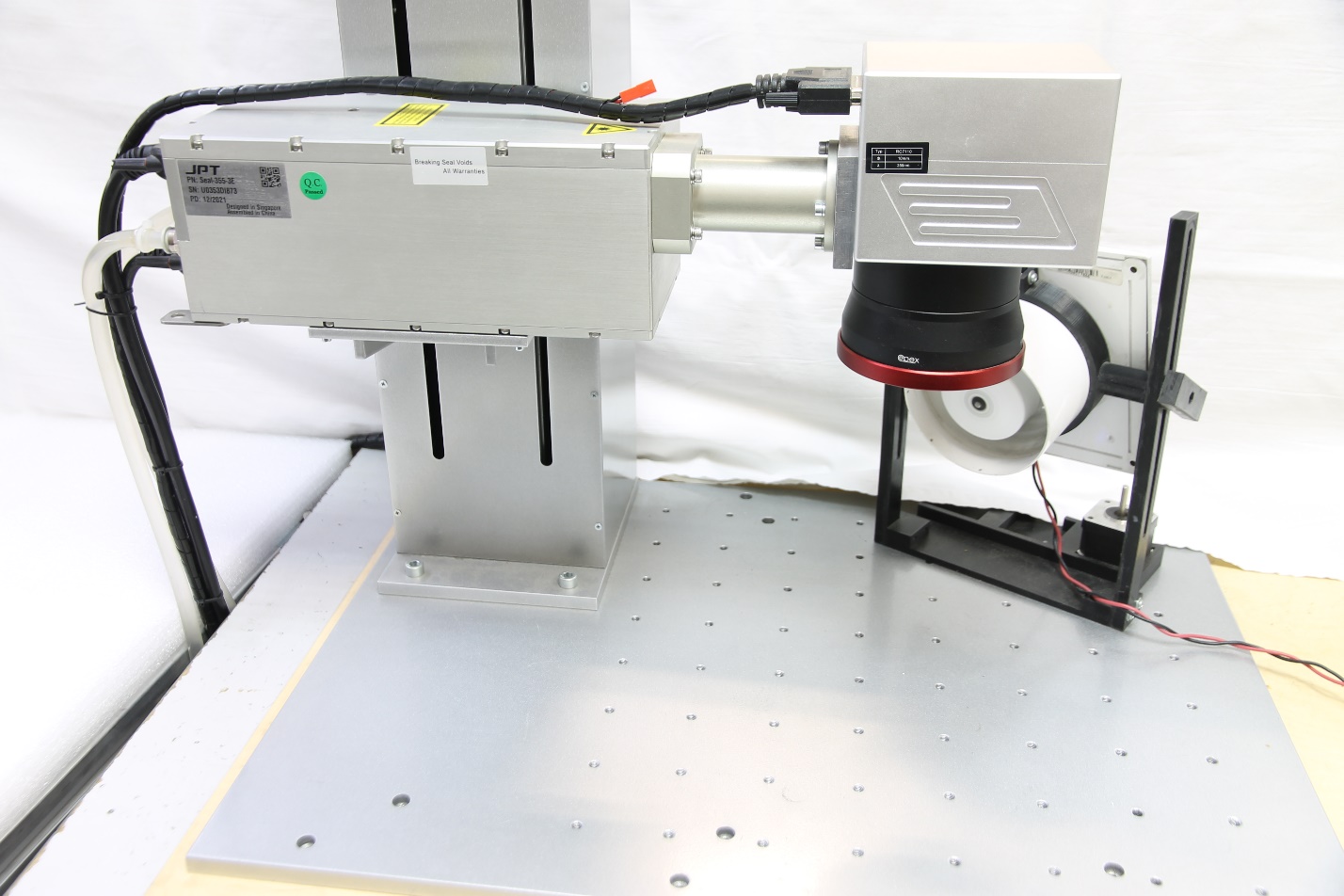

To complete the task, we are using an Endurance 3 watt UV laser machine with a JPT seal-355 UV laser with a wavelength of 355 nm , with an average power of 3 W was used

Endurance 3 watt UV (355 nm) laser module

Pulse duration at 30 kHz is less than 18 ns . The laser operates in the frequency range from 20 kHz to 150 kHz. To maintain the laser operating temperature (25 °C), a water cooling system is used.

The machine is equipped with a galvanometer RC7110 with a lens “SL-355-110-160-D10-LP” installed on it, having a focal length of 160 mm and a working area of 110 mm by 110 mm.

The machine is controlled using the EzCad program .

General view of the installation

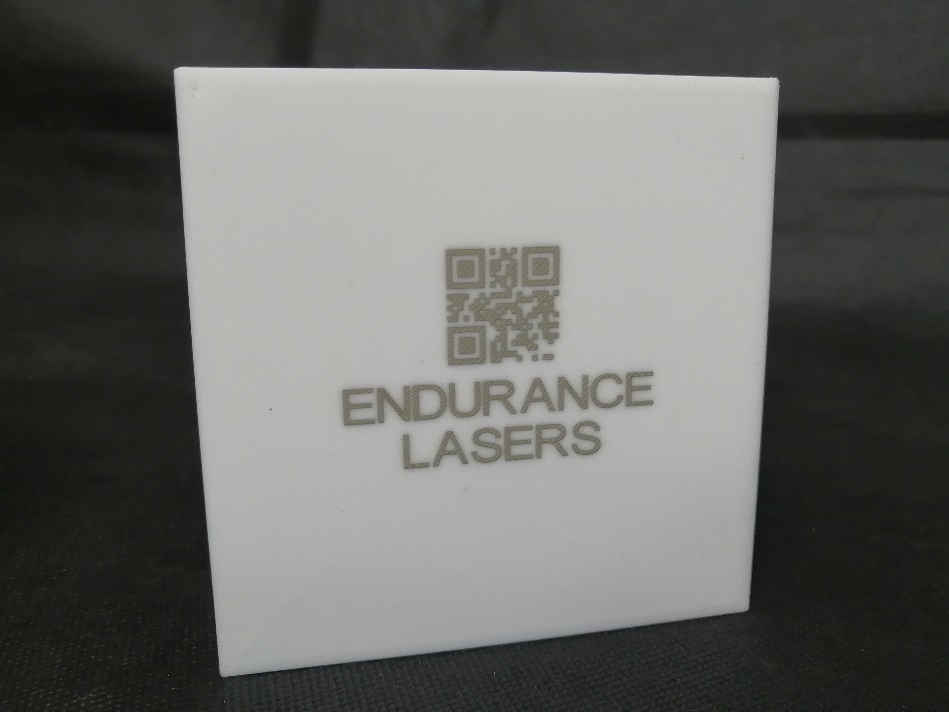

For marking, a two-dimensional barcode of QR code format was used with the inscription “ ENDURANCE” encoded in it LASERS .”

The width was set to 20 mm.

Barcode marking was done by outlining each element of the QR code along the contour followed by filling the contour. The distance between the fill lines was set to 0.05 mm.

White PETG plastic:

Based on the test results, the following labeling parameters were selected:

Frequency (kHz): 30

Q Pulse Width (us): 1

Speed (mm/s): 1000

Loop Count: 1

Start TC (us): 150

Marking on white Petg plastic

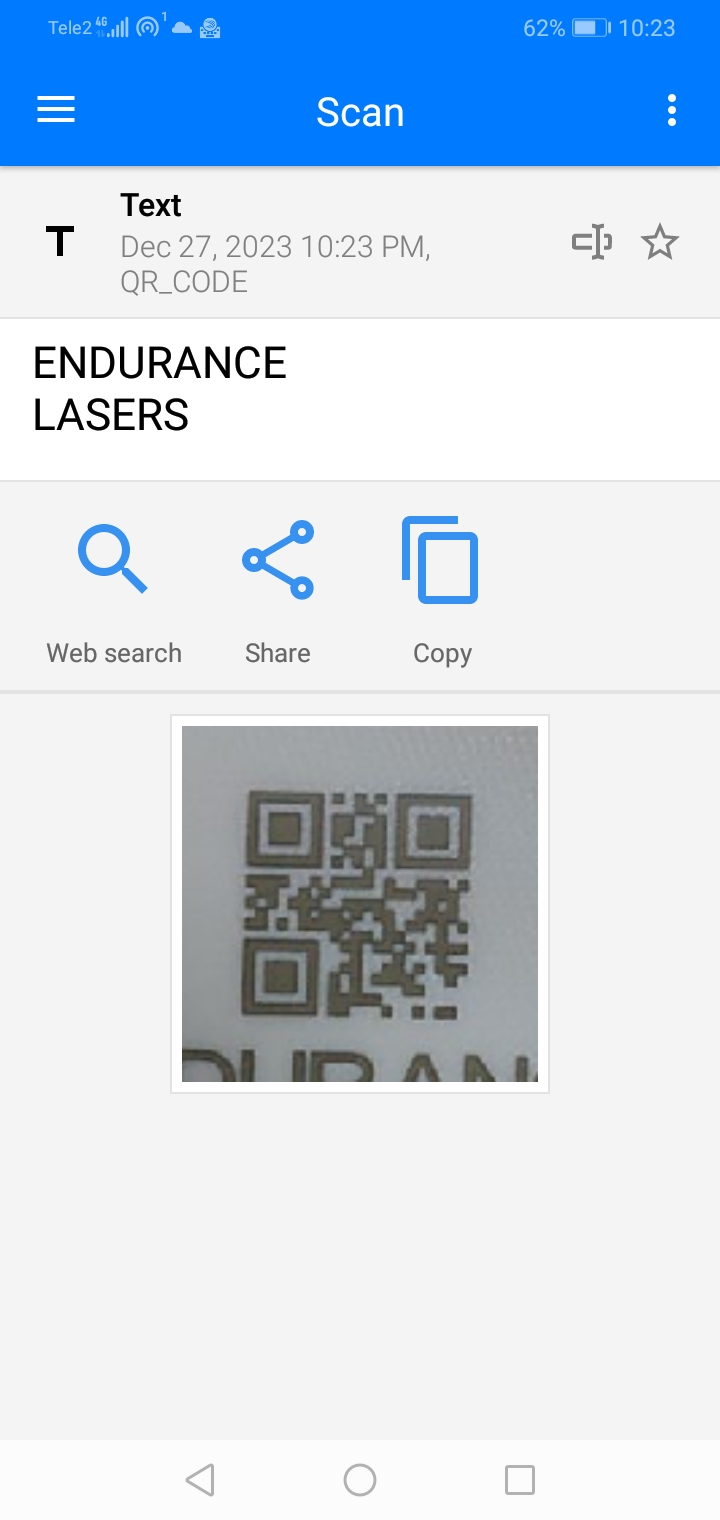

Barcode Reading

| QR code |

|

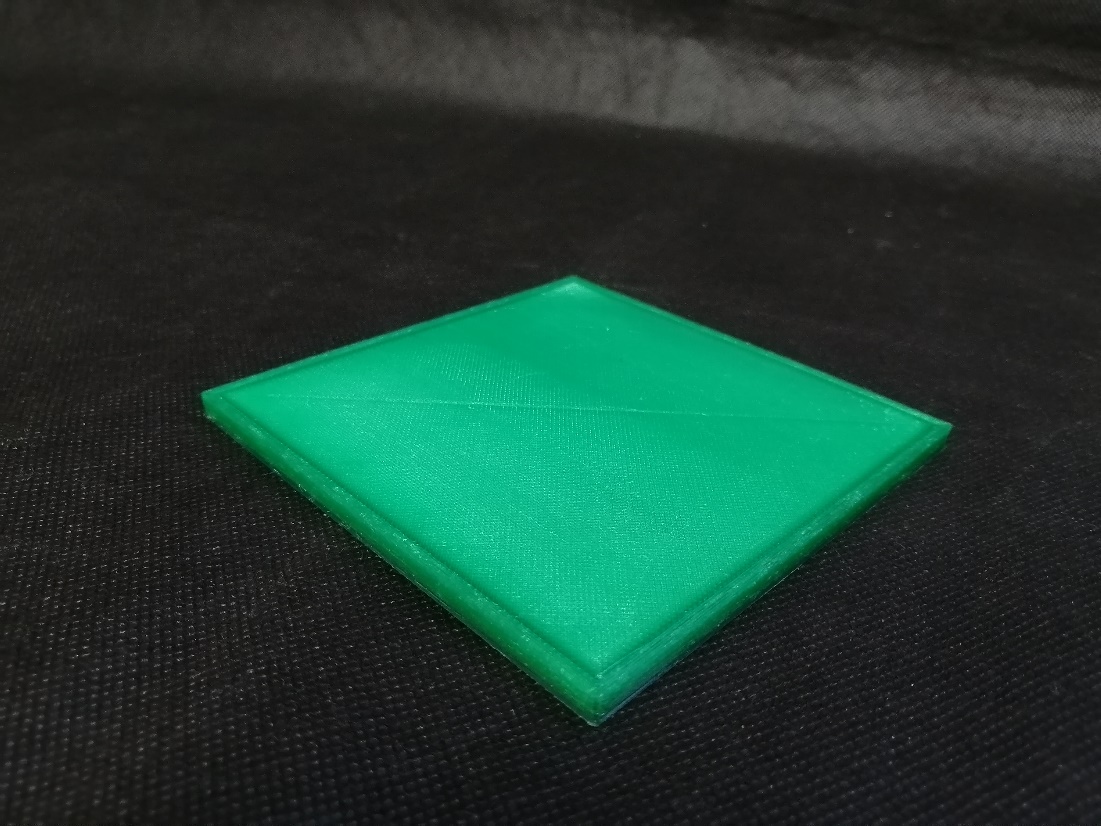

Green PETG plastic :

Based on the test results, the following labeling parameters were selected:

Frequency (kHz): 60

Q Pulse Width (us): 1

Speed (mm/s): 1000

Loop Count: 1

Start TC (us): 150

Marking on green Petg plastic

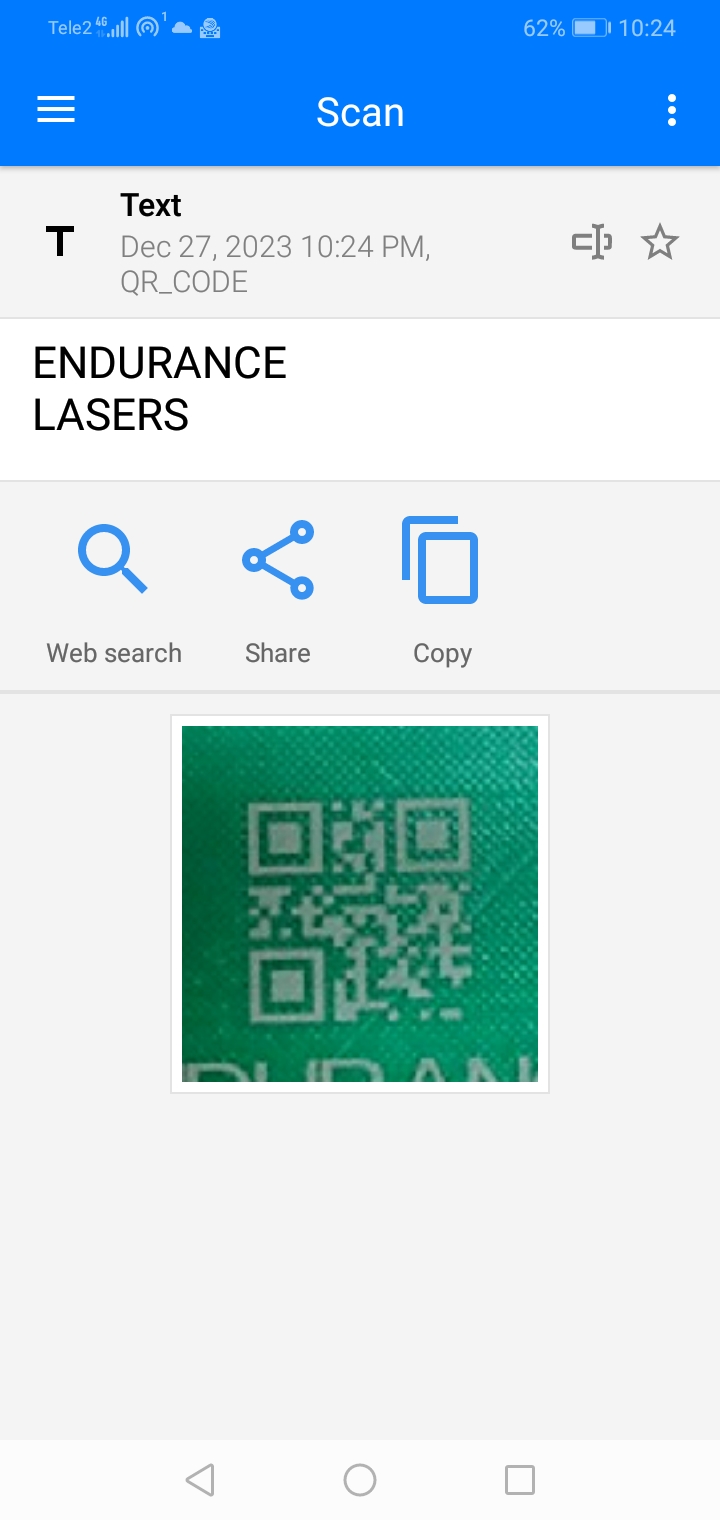

Barcode Reading

| QR code |

|