Instructions for FieldBest_I Laser Power Meter

Note: When measuring laser with a pyroelectric probe, do not directly touch the probe housing with your hands to measure, otherwise the power measurement will be inaccurate, especially for low-power probes, when measuring low-power lasers, there may always be negative values, which should be fixed with a bracket The probe is used for measurement; do not place the probe in a place with airflow for measurement, as the airflow will affect the stability of power measurement.

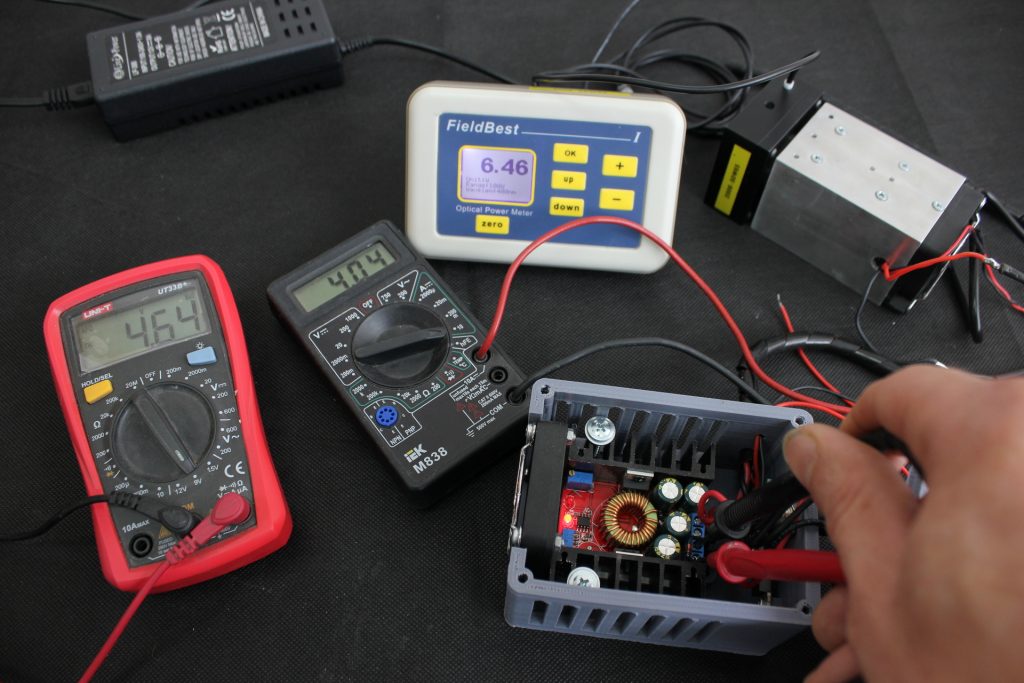

Appearance and connection description

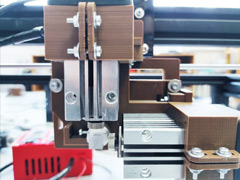

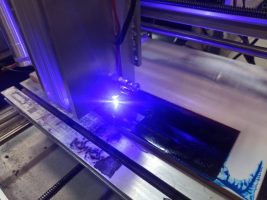

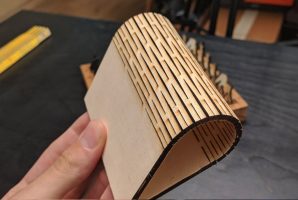

TOP SALES! The best laser head for your 3D printer / CNC machine / engraving frame.

The power meter consists of three parts: meter, probe and power supply, as shown (note: power supply is not shown).

The input of the power supply is alternating current between 100V and 240V, the output is 5V direct current, and the middle of the output plug is positive.

The 12mm circular hole in the middle is where the laser is received. The diameter of the incident laser spot must be less than 8mm, otherwise the spot may be trimmed and the power measurement will be inaccurate; the lower part of the probe is a support rod (customers need to configure it) .

The 12mm circular hole in the middle is where the laser is received. The diameter of the incident laser spot must be less than 8mm, otherwise, the spot may be trimmed and the power measurement will be inaccurate; the lower part of the probe is a support rod (customers need to configure it) .。

There are three connectors: 5V, USB and HEAD. 5V is a DC 5V power input socket. It is a standard 5.5-2.1 DC socket. The inside is outside. Users can use our standard configuration. Power supply, you can also use your own 5V power supply; USB is a standard mini-usb female socket, and users can connect to the computer through this socket and a USB cable (note: this USB port cannot supply power to the meter); HEAD is a BNC female socket , This connector connects the probe.

Installation and use

Connect the BNC connector at one end of the coaxial cable of the probe to the BNC connector marked HEAD on the back of the meter, and insert the DC plug of the power supply into the DC socket marked 5V on the back of the meter. Put the laser into the middle of the probe hole (be careful not to hit the upper side of the probe shell, otherwise the measurement will be inaccurate). As long as the power has been supplied, the meter will start immediately, first display the Welcome word, and then enter the power reality interface. The first line on the LCD screen displays the laser power. For the laser power of the pyroelectric probe, as long as the range is not exceeded and the large value on the first line of the LCD screen is stable, this value is the measured laser power.

Note that because the principle of the pyroelectric probe is to measure the temperature difference between the photosensitive surface and the probe housing when measuring the laser power with a pyroelectric probe, do not directly touch the probe housing with your hands to measure, otherwise the power measurement will not be accurate, especially for low-power The probe may always show negative values when measuring low-power lasers. The probe should be fixed with a bracket for measurement; do not place the probe in a place with airflow for measurement. Airflow will affect the stability of power measurement.

Button setting operation

All parameter settings on the meter head and page conversion on the LCD screen are realized through the buttons on the front. The specific functions are as follows:

- When there is no letter flashing on the LCD screen, press the “+” key or “-” key to make the LCD screen display a different interface.

- When there is no letter flashing on the LCD screen, press the “OK” button once, and the letter corresponding to the corresponding parameter will flash on the LCD screen.

The flashing parameter can be changed at time.

- When there is a letter flashing on the LCD screen, press “OK” again, and the relevant letter on the LCD screen will stop flashing.

- When a letter flashes on the LCD screen, press the “+” or “-” key to change the setting of the corresponding parameter.

- When a letter flashes on the LCD screen, press and hold the “up” or “down” key to switch the cursor between different parameters.

Page introduction on the LCD screen of the meter head

- Main interface: the first line shows the power value; the second line “Unit: mW” represents the unit of power reading, the unit may be W (watt) or mW (milliwatt), this unit is not available to users Directly change, it is automatically changed according to the set range; “Range: 100mW” in the third line represents the set range, the range display may be 100mW, 1kmW, 1W, 10W, 100W, 1kW, depending on the configuration The probe is different, the setting in the meter head is different, the range setting is also different; the fourth line “Wave: 650nm” represents the wavelength setting, for the thermoelectric probe, the wavelength is displayed as an integer of 100nm, such as 500nm, 600nm, 700nm, etc. For radio and television probes, the wavelength is displayed as an integer of 10nm, such as 550nm, 560nm, 570nm and so on. It should be noted that for the pyroelectric probe, it is meaningless to change the wavelength. If the wavelength is displayed as 600nm when the customer receives it, it means that we are a power meter calibrated near 600nm, such as 650nm. If it displays 500nm, it means that it is calibrated near 500nm, such as 532nm. Even if the wavelength is modified, the calibration coefficient is the same; for the photoelectric probe, the wavelength is calibrated in units of 10nm. If customers need to measure the power of different laser wavelengths, they need to set the wavelength as close as possible to the measured laser wavelength, such as measuring For 532nm laser, the wavelength should be set to 530nm.

SETTING interface :the first line “Backlight: on” is the LCD backlight switch setting. When this parameter is flashing, you can change the backlight to on or off by pressing the “+” or “-” key; the second line is “Average: 1” is the power average times setting. When this parameter is flashing, you can set the power average times in the range of 1-100 by pressing the “+” or “-” key. If the value is 1, it means that no averaging is performed; the third line ” Atten:1.000″ is the probe attenuation setting. When this parameter is flashing, this value can be changed within a certain range by pressing the “+” or “-” key. This function has the same effect for all wavelengths; the fourth line “Save_All: Sel” is used to save all parameter settings. When this parameter is flashing, you can activate this operation by pressing the “+” or “-” key. It takes about 3 seconds. Once saved, all the parameters of each page (including those at different wavelengths) Calibration factor) will be saved to EEprom in the meter computer.

CALIBRATION interface :The first line “Y=a*X+b” indicates the conversion formula relationship from voltage to power, where a is the product coefficient, b is the compensation value, X is the read voltage, and Y is the displayed power value; “&600nm” on the right indicates the wavelength at which the calibration is located. This value is the same as the value of the wavelength setting of the main interface. When the wavelength of the main interface changes, the value here will also change; the fourth line P=-0.0mW is the measured laser The value of the power; the fifth line is the setting of the product coefficient a, and its value can be set between 0.0001 and 9.999; b is the setting of the power compensation value, and the value setting range is -3.999 to 3.999.

It should be noted that for the photoelectric probe, the value of changes with the wavelength, with a recording point every 10nm; for the thermoelectric probe, the value of a does not change with the wavelength.

Download all files you need to work with FieldBest laser power meter (ZIP)

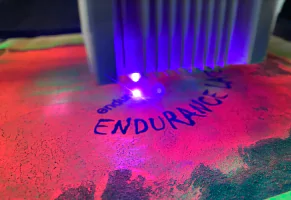

Endurance does not recomend FieldBest laser power meter. We used 3 units and all of them burned after 2-3 months of usage. It is impossible to repair them since the mainboard is glued.

eBay support does not reply about our claims!