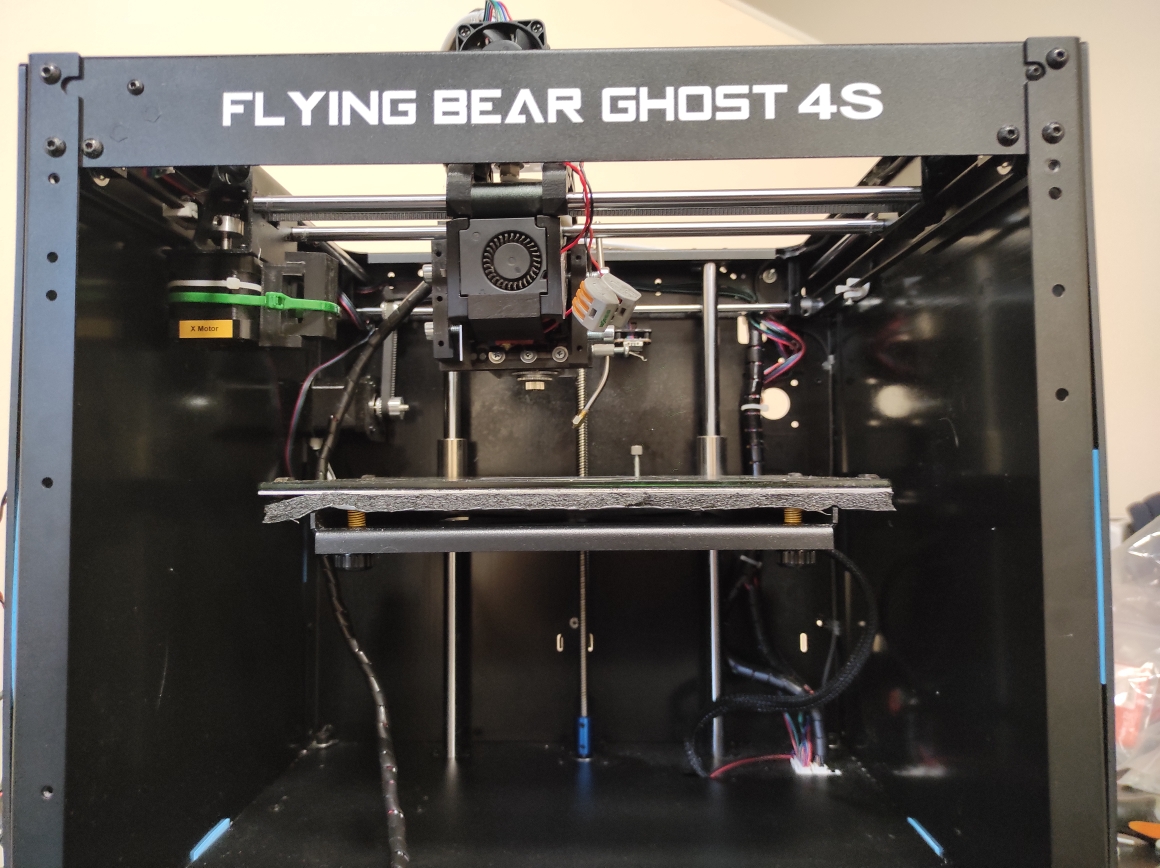

It is very easy to setup an Endurance laser on almost any 3D printer or CNC machine.

Takes less than 60 minutes to setup. Usually something like 15 minutes

Check compatibility list >>>

Compatible 3D printers and CNC machines – compatibility list

A lot of videos about wiring on YouTube Playlist

Prepare 10 watt / 10 watt+ laser for the first run

How to fix, install the laser diode, thermometer, connect TTL wires.

Connecting an Endurance laser to different boards (CNC, CNCC, Eleksmaker, etc.)

How to hook the laser to Eleksmaker

How to hook the laser to Anet 3D printer

How to hook the laser to WanHao 3D printer

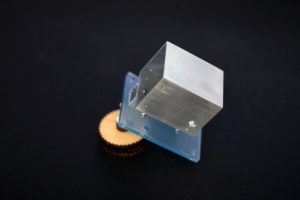

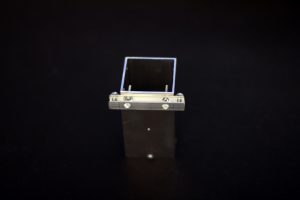

Learn more about Endurance mounting brackets

Download advanced and basic mounting brackets (STL files on Thingiverse)

An Advanced and basic mounting brackets: https://www.thingiverse.com/thing:4444946

How to install the laser on a 3D printer

Subscribe on our Youtube channel and do not miss our news and guidance.

If you are not able to watch our video – let us know. All video are free for Endurance customers. We have more than 500 video guidance and tutorials.

- Depending on your printer, add a header to the Endurance laser terminals. This will connect in place of your extruder’s heater.

- If you have a CNC tool with a spindle, rather than a 3D printer, the Endurance laser Assembly CNC (link) instructions show how to switch between laser and spindle.

- Mount the Endurance laser on your extruder, either by screws or zip ties.

- Lower the Z-axis. If you have a kickstand, lower it in place.

- Screw the lens assembly on the bottom of the laser module almost all the way out — it should not come off (if it does, just screw it back in a little). Make sure it is fully extended.

- Put your protection plate on the print bed, if you have one. If you don’t have one, make sure to get yourself a protection plate because the laser can and will damage your device’s build plate.

- With protection goggles on, disconnect your printer’s extruder and connect the Endurance laser.

- Send the M104 S100 command to your printer (or otherwise turn on the extruder). The laser will light up. If it doesn’t, switch the + and — contacts around; the extruder heater is resistive, so there is no standard configuration for it. The Endurance laser has a protection diode and is safe to connect backwards, although it won’t work, so just try again with the connector flipped!

- Use the crown on the bottom of the laser assembly to focus the laser by screwing the lens back in. The optimal focal distance is 3 to 4 inches, depending on your printer or CNC setup. We recommend using a piece of paper or cardboard as the target — when you see smoke, your laser is focused!

- Send the M104 S0 command to turn the laser off!

A 10 watt Plus laser is installed on Prusa 3D printer

How to test the laser. An easy way

Laser power supply

All Endurance lasers work from 9 – 16V.

If you have 24V power output on your 3D printer or CNC router – let us know and we will ship you step-down “buck” DC/DC converter.

How to find a PMW pin on your controller – a detailed video guide!

About laser thermal stability. Setting up 10 watt PLUS PRO and 10 watt SE laser TEC cooling (Peltier) with DC/DC external box.

Subscribe on our Youtube channel and do not miss our news and guidance.

If you are not able to watch our video – let us know. All video are free for Endurance customers. We have more than 500 video guidance and tutorials.

High-quality standard

Multi-level testing system.

Industrial components.

Ultra reliable

The guaranteed duration of the continuous operation ~48-72 hours.

True continuous power output

Our products have the rated power output as advertised – unlike Chinese analogues.

TTL mode

Can be turned on and off with 3.5-24V.

Variable power output.

Plug and play

Universal and compatible mount.

Compatible with most 3D printers and CNC machines.

Friendly return policy

Do not like the laser?

Simply return within 30 days and get a full refund.

Real-time advice

We assist and give advice by Phone / Email / Facebook messenger / Telegram / Whatsapp / Viber.

Professional support

We help to install and tune the laser. We offer qualified after-sales support.

Everything you need

We ship everything you need in one parcel to get started.

Immediate delivery

We ship all units within 4-24 hours. DHL express delivery allows you to get the package in 3-5 days.

Lifetime warranty

All our lasers are tested and could work up to 10000 hours.

Upgrade option

Do you have an old model? Upgrade your unit with more powerful one.