An introduction

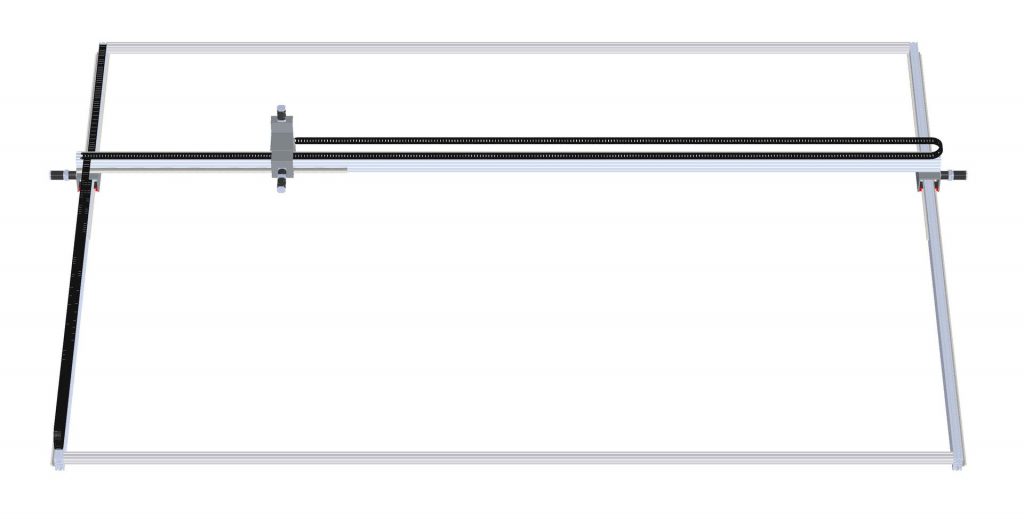

A 3D model

Endurance has built one of the biggest engraving frames in the world!

- The total size is 6×4 meters (18×12′)

- Working size is 5.5×3.5 meters (16×11′)

- Ultra-reliable stepper motors controller by Purelogic.

- Professional laser box with drivers and controlling systems

- Ultra-high precision: accuracy is 0.1 mm.

- Maximum working speed is 10000 mm/min

- It can work in horizontal and vertical positions.

- It can operate with a diode laser, DPSS laser or a spindle.

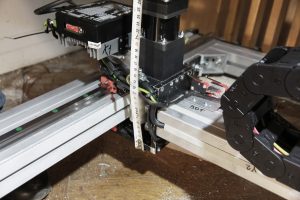

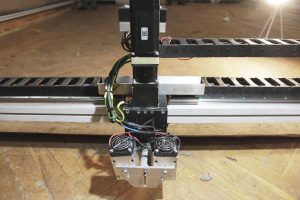

Mechanical components

ALUMINUM construction profile without coat, with a cross-section of 50х100, sections 6 m long —2 pcs

ALUMINUM construction profile without coat, with a cross-section of 50х50, sections 4 m long —- 2 pcs

ALUMINUM construction profile without coat, with a cross-section of 50х100, sections 4 m long, —- 1 pc

Angular connector 50×50 + connection elements — 4 pcs

Solid aluminum sliding block, with a groove (slot) of 10 — 10 m

Open cogged belt XL 5.08/20mm — 34 m

Pulley XL Z=12 for a belt of 20 mm —- 6 pcs (outside diameter 19 mm )

Puller 20 mm —- 12 pcs

Rail GHR15 L: 4 m — 6 pcs

Rail GHR15 L: 2 m — 4 pcs

Carriage HSAC GHH15CA — 12 pcs

Stopper plug CAPM4-GHR15 —- 500 pcs

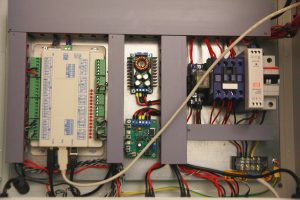

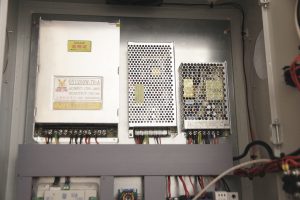

Electronic components

| Axis Х | ||

| Description | Model | Features |

| Stepper motor with encoder | PL57H1404-D8-1K | 57×126 mm, 2 phases, 28 kg.cm, spindle 8 mm, current 4.2А, step 1.8°, 0.7 Om, 1000PPR |

| Driver of a servo-stepper motor (SSM) | PLDS880 | driver of a SSM or a stepper motor … … 80V/10А/200kHz |

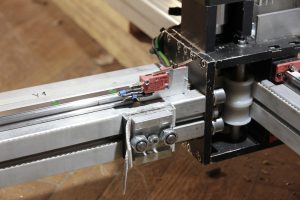

| Microswitch | XV-156-1C25 | 7.5A/250VAC, reversible, НР+НЗ, roller, IP40 |

| Axis Y | ||

| Description | Model | Featurs |

| Stepper motor with encoder | PL57H1404-D8-1K | 57×126 mm, 2 phases, 28kg.cm, spindle 8 mm, current 4.2А, step 1.8°, 0.7 Оm, 1000PPR |

| Driver of a servo-stepper motor (SSM) | PLDS880 | driver of a SSM or a stepper motor … … 80V/10А/200kHz |

| Microswitch | XV-156-1C25 | 7.5A/250VAC, reversible, НР+НЗ, roller, IP40 |

| Wires and connectors | ||

| Description | Model | Features |

| Signal cables 18+18+14+10з | PVC0.2x8STP | Signal shielded, wires pair, 8 pcs.(4 pairs)*0.2 mm²) |

| Signal cabpes 14+8+18+12+15+19+18Л+21з | PVC0.2x4STP | Signal shielded, wires pair, 4 pcs.(2 pairs)*0.2mm² |

| Power supply cables 18+18+14+18Л+12з | PVC1.0x4S | Signal shielded, 4 pcs.*1.0mm² |

| Connector | YD28J4Z | Block plug, 4 конт??? |

| Connector | YDA28K4TS | cable socket, 4 конт??? |

| Wires, cables and supply units | ||

| Description | Model | Features |

| Supply unit70В | GY1200W-70-A | 70В 17А |

| Supply unit24В | NES-150-27 | 24В 6.3А |

| Ferrite bread for a cable of 5 mm | ||

| Others | ||

| Description | Model | Features |

| Controller | RDC6442G | |

| Display | RDC6442G | |

| For assembling of a control box | ||

| Description | Model | Features |

| Mini connector 4pin | DS1110-01-4 | (block cable)\Connfly |

| Switch | S202Z-2(S202UZ-2) | Electrick lock for РЭА \Jin Tay |

| Backlit toggle switch ON-OFF | ASW-14D (red) | (20A12VDC) SPST 3P\Jietong Switch |

| Backlit toggle switch ON-OFF | ASW-14D (green) | (20A12VDC) SPST 3P\Jietong Switch |

| Ventilator 220V | EC1225A2HBL | 120х120х25 mm, ball bearing, 2000 rpm|Evercoo |

| Relay 1 пер | HHC68A-1Z-24D | 24VDC / 15A,240VAC\NCR |

| Колодка реле | PTF08A | HHC68A-2Z (LY2)\NCR |

| Решетка | FGF-120/M silver | Fan filter120х120 mm (metal)\Evercool |

| Supply unit | MDR-10-24 | 24В,0.42А,10 W\MEAN WELL |

| Button | КЕ-021 | “Stop” red. гриб. |

| Signal lamp | XB7EV03MP | 22mm230V green. (LED) |

| Signal lamp | XB7EV05MP | 22mm 230V yellow (LED) |

| Signal lamp | XB7EV04MP | 22mm 230V red (LED) |

| Signal lamp | XB7EV04BP | 22mm 24V LED red |

| Button SB-7 | BBT40-SB7-K06 | Start green |

| Contactor | ПМЛ 1160ДМ | 16А 220AC УХЛ4 Б КЭАЗ 110546\КЭАЗ |

| Signal lamp | XB7EV03BP | 22mm 24v LED green |

| Supply block | LRS-150-12 | 12V,12.5А,150W |

| Male tab | НШВИ 0.25-8 | Blue 0.25 mm 2. |

| Male tab | НШВИ 0.5-8 | white 0.5mm |

| Male tab | НШВИ 0.75-12 | gray, 0.75mm2, L 12mm |

| Male tab | НШВИ 1.5-8 | (8mm) black 1.5mm2. |

| Faston connector 6.3 mm | KLS8-01109-FDFD1.25-250 | Fully insulated, wire 0.25-1.5 (red) |

| Faston connector 6.3mm | KLS8-01109-FDFD2-250 | Fully insulated, wire 1.5-2.5 (blue) |

Testing process

| Failures that were fixed while testing | |

| Proper belts tightening | |

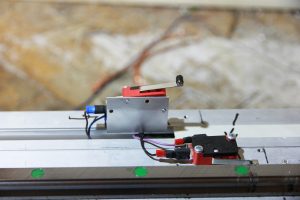

| Adding 1:5 gearbox on X axis (2 motors) | |

| More rigid cable channel mount | |

| Additional lubrication of bearings on X axis | |

| Installing the stud inside the flange from the engine to the gearbox | |

| Added inversion of rotation of one of the engines along the X axis for the correct movement of the portal in the same direction. | |

| Correct coefficients are set for step values along the X and Y axes to ensure accuracy of movement. | |

| The correct size of the working field is set to prevent it from exiting. | |

| The operation of emergency limit switches on the X and Y axes was tested. | |

| The software protection work on the voltage on the MO2 board is disabled to ensure the operation of 2 lasers. | |

| Additional stretching belts | |

| Second bearing improvement | |

| Stationary belt tensioners were made and installed to adjust the tension | |

| Fixed scrolling of drive pulleys on the X and Y axis. | |

| Major checkpoints tests | |

| Max speed | 10m/min |

| Max weight | 10 kg on a X and Y |

| Vertical work | did not test |

| Horizontal work | tested |

| Non-stop operation | 4 hours |

| Accuracy | 0.1 mm |