All you need to know about hazardous materials for laser cutting / laser engraving! MUST READ IT!

Let’s start that there are several types of plastic.

Combustion and melting of the plastic.

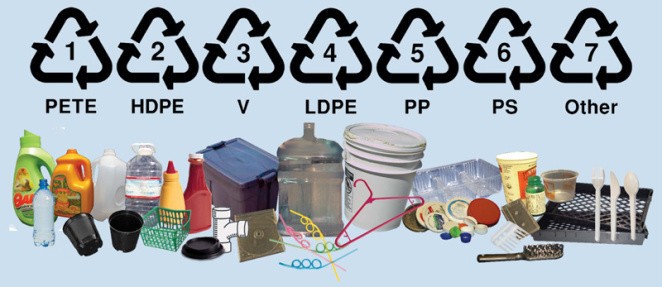

Some items made of plastic are marked with a special numeric label from 1 to 7. Every number, except 7, corresponds to a certain type of polymeric material. The number 7 denotes all the rest, non-plastic materials. The plastics falling within the 1 to 6 groups belong to the category of thermoplastic, that means that they grow soft when heated. Various types of plastic react in a different way to fire: some begin to smolder, some melt, some don’t react at all.

Most plastics are potentially dangerous as they might emit toxic substances, which is associated with their components and the technology of their production. But among them, there are also more harmless types.

PET or PETE – polyethylene-terephthalate

PET is the most widely used plastic in the food industry, especially in bottle manufacturing. It is also a very popular stuff for making. There are many ways of plastic bottles processing. You can read about the industrial processing of PET here.

PET melts at 260 °С; at 60 °C it grows soft and gets out of form.

Danger:

PET is known to have antimony and cancerogenic. When keeping water in PET bottles, these elements might go to water, especially when heated. These substances can also be emitted in combustion and melting.

Conclusion:

There’s a potential danger of hazardous elements emittance during burning and melting. There are plenty of ways to do crafts out of PET bottles without heating.

To reshape a PET item it’s better to heat it in boiling water. It’s safer than to breathe in the vapor of dry-heated plastic. Remember, you need to work outdoors or in a well-ventilated room.

HDPE – high-density polyethylene or low-pressure polyethylene

The HDPE mark means that the melting of this plastic is relatively safe. Bottles for milk and detergent are made of this plastic.

Necessary to know:

One can use HDPE containers or bottles for water because they are not prone to leaching. HDPE is very durable plastic, and it doesn’t go soft, if only at a VERY high temperature. This plastic is not flexible enough but it is good for rigid structures.

Conclusion:

One can use this plastic without worries. This plastic melts at about 120-135 °С.

PVС – polyvinyl chloride

Vinyl LPs. Melting of PVC plastic is very dangerous

PVC is the most dangerous plastic produced today. Most LPs are made out of PVC. Being unaware of the potential danger of PVC many people heat it and burn it. The melting temperature of PVC is 150 – 220°C, but it starts getting soft and losing form at 65 – 70 °С.

Danger:

PVC releases carcinogens and lead. When heated it also releases dioxins, most dangerous pollutants, and toxins.

Conclusion:

It is possible to use PVC but to heat or burn it is VERY DANGEROUS!!!

If you still need to melt a PVC item, it’s better to use boiling water, without exposing the material to open fire. And do it in a well-ventilated room.

LDPE – low-density polyethylene or high-pressure polyethylene

It’s marked as LDPE. LDPE melting is relatively safe.

LDPE is one of the less hazardous plastics. It is used to make device buttons, polyethylene film, plastic bags for grocery and garbage, foodtainers.

What you need to know:

LDPE is a durable material but less strong than HDPE. It melts at a rather high temperature of 90 °С.

Conclusion:

HDPE is a rather safe plastic in use. It needs much warmth to be melted. But you need to be careful, as plastic bags might easily catch fire.

PP – polypropylene

Plastic caps are made out of polypropylene. Its melting and burning is relatively safe. PP is safe plastic. It is used to manufacture bottle caps, dispensers, plastic dishes. It is hard-melting. Its melting temperature is 160 – 170 °С but it gets soon hot. Read about its recycling in this article.

Pay attention:

Polypropylene is rather safe, but some researchers showed that some type of polypropylene could release biocide. So, one needs to make use of it with care.

PS – polystyrene

It is a kind of foam plastic. Its melting and burning are very dangerous. This type of plastic is very widely used for disposable tableware, packaging, children’s toys, thermal isolation, and other construction materials. It is necessary to avoid heating of polystyrene because it contains styrene.

Some information about the recycling of polystyrene is to be found in this article.

Its melting temperature is 240 °C, but it starts losing shape at 100 °C. A specific smell appears when heated.

Danger:

It releases a very dangerous poison and cancerogenic – styrene.

Conclusion:

Never heat polystyrene. But if absolutely necessary, do it in a well-ventilated room.

OTHER plastics.

There are safe and dangerous types. PLA, for example, belong to biodegradable plastics. It is safe to work with it. Polycarbonate is less safe. According to some researches, it can release bisphenol-A.

It is necessary to handle unknown plastics (without marks) with great care. Their compositions, as well as a potential danger, are not known.

Don’t burn PVC and PS.

This article was written to give you a better understanding of how to deal with plastics in terms of laser cutting or laser engraving. Keep in mind that almost all plastic materials are toxic and you have to have a fume extractor to do any laser cutting or laser engraving.

Be very careful with that!

Read more

NEVER CUT THESE MATERIAL (PDF)

Keywords: HDPE, V, LDPE, PP, PS, polycarbonate, PEG, ABS, PLA, plastics. Laser plastics cutting