When you plan to use a laser for laser cutting or laser engraving it is quite obvious that the more powerful laser the better, but even that might not be enough to make your dreams come true.

More powerful does not mean more efficient.

For example, you cannot cut transparent acrylic with the 445 nm wavelength no matter what laser power. The reason is simple: the beam with this wavelength goes through the material and does not interact with it.

- Laser power.

- Laser wavelength.

- CW / impulsive mode.

However, this is not all. This is centers around the laser but what about the material?

The properties of the material you are going to cut, its shape and thickness matter as well.

The following properties of the material should be taken into account:

- Color.

- Density.

- Heat capacity and thermal conductivity.

- Absorption level for particular wavelength.

- Burning / melting temperature.

- Sensitivity to oxidation.

So when you plan to engrave or cut you need to understand how these properties will effect engraving or cutting processes.

Let me explain it in details.

Color – when using a laser in the visible light spectrum, the darker the material the better for engraving or cutting. The reason is simple – a darker surface reflects less light, that is, more power is applied to the engraved spot. If the material is transparent the laser beam goes through without affecting it.

Density – is a very important property. For example, it’s much easier to cut PVC or PLA than hard wood. More densed material needs more power to cut it through.

Heat capacity and thermal conductivity – it’s easier to engrave on wood and plywood than on metal. More power is required to engrave materials with high thermal conductivity, such as: silver, copper and gold.

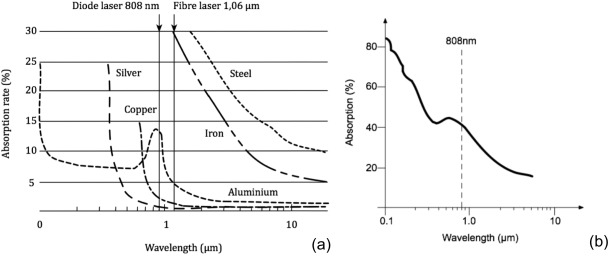

Absorption level for particular wavelength – The absorbtion level depends on the wavelength and the tructure of the material. Every material has its own level of absorbtion for various wavelengths. Thus, aluminum is more sensitive to the 800 nm wavelength.

Burning / melting temperature. The higher the melting temperature the higher power you need to melt the material. For example, the melting temperature of aluminum is about 650 C while that of aluminum oxide (Al2O3) is over 1000 C, which makes engraving on aluminum plates a more complicated process since you need to burn through the aluminum oxide film first covering an aluminum surface.

Sensitivity to oxidation. Engraving is possible due to the process of oxidation taken place on the material surface in the open air. It means that engraving on gold is not possible since gold does not oxidize (does not interact with oxigen).

Hope that this info will help many laser makers in their endeavors.